Method for degrading organic dye through metal organic framework film based on metalloporphyrin

A metal-organic framework, organic dye technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, water pollutants, etc., to achieve the effect of convenient recycling and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

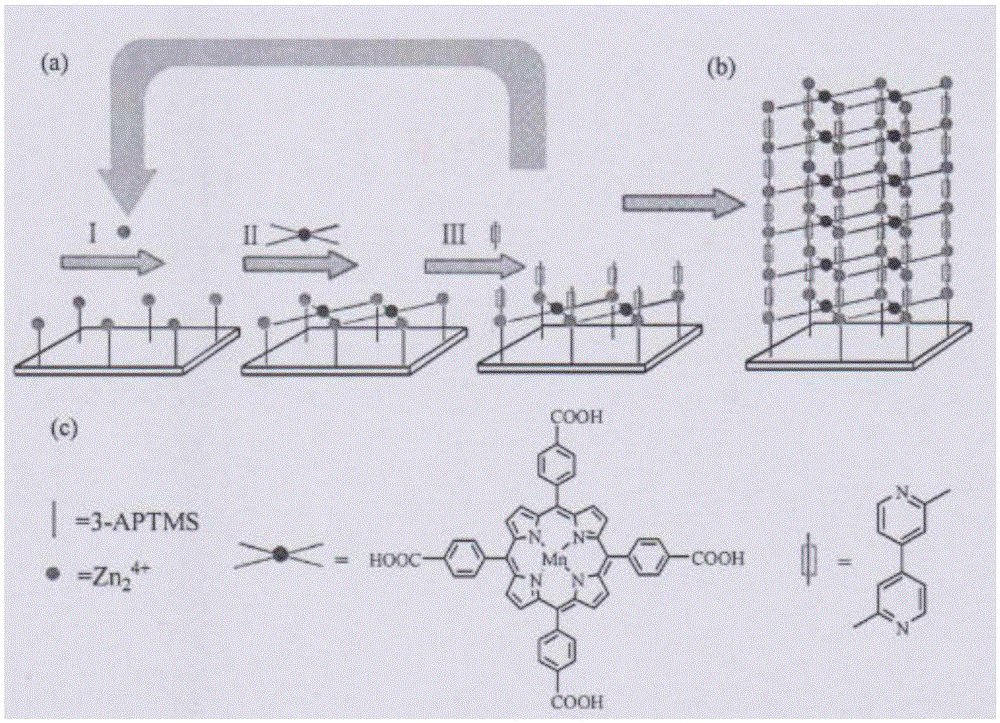

Image

Examples

Embodiment 1

[0013] The APTMS-treated glass substrates (2x3cm) were successively dissolved in zinc acetate (0.1mmol / L), 5,10,15,20-tetra-p-carboxyphenylmanganese porphyrin (2μmol / L) and 2,2'-bis Soak in an ethanol solution of methyl-4,4'-bipyridine (2 μmol / L) at 40°C for 10-12 minutes, wash with ethanol before each soaking, one cycle of soaking is a growth cycle, and 7 cycles of soaking to get a growth cycle A 7-layer MnPor-MOF film was fabricated. Place it in a mesh support and suspend it in methylene blue aqueous solution (4×10 -5 mol / L, 50ml), and placed in the dark for 30 minutes to make the catalyst reach adsorption-desorption equilibrium in the reaction liquid. Then irradiate the glass substrate with 300W xenon arc lamp, H 2 o 2 and methylene blue catalytic photolysis system. The change of absorbance of methylene blue at 665nm at different irradiation times was measured by UV-vis spectrometer to indicate the degree of degradation of methylene blue. After 180min of reaction, the d...

Embodiment 2

[0015] The APTMS-treated glass substrates (2x3cm) were respectively dissolved in zinc acetate (0.1mmol / L), 5,10,15,20-tetracarboxyphenylcobalt porphyrin (2μmol / L) and 2,2'-bis Soak in an ethanol solution of methyl-4,4'-bipyridine (2 μmol / L) at 40°C for 10-12 minutes, wash with ethanol before each soak, and soak for 14 cycles to obtain a CoPor-MOF film with 14 layers grown . Place it in an aqueous solution of Rhodamine B (4×10 -5 mol / L, 50ml), then use a 300W xenon arc lamp to irradiate the glass substrate, H 2 o 2 and rhodamine B catalytic photolysis system. The degree of degradation was expressed by measuring the change of absorbance at 554nm by UV-vis spectrometer, and the degradation rate of rhodamine exceeded 95% after 120 minutes of reaction.

Embodiment 3

[0017] The APTMS-treated glass substrates (2x3cm) were successively dissolved in zinc acetate (0.1mmol / L), 5,10,15,20-tetra-p-carboxyphenylmanganese porphyrin (2μmol / L) and 2,2'-bis Soak in an ethanol solution of methyl-4,4'-bipyridine (2 μmol / L) at 40°C for 10-12 minutes, wash with ethanol before each soaking, one cycle of soaking is a growth cycle, and 14 cycles of soaking to get a growth cycle A 14-layer MnPor-MOF film was fabricated. Place it in methylene blue (1×10 -5 mol / L), Rhodamine B (1×10 -5 mol / L), methyl orange (2×10 -5 mol / L) mixture solution (50mL), then irradiate the catalytic system with a 300W xenon arc lamp, and measure the change of absorbance at 665nm, 554nm and 464nm by UV–vis spectrometer to indicate the degree of degradation, and the degradation rate after 120min of reaction 96%, 95%, 97%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com