Zinc oxide nano-sheet cluster and preparation method thereof

A zinc oxide nanometer and sheet cluster technology is applied in the field of chemistry, which can solve the problems of increasing cost and energy consumption, and achieve the effects of small size dispersion, simple process and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a) Adding a certain amount of zinc acetate and sodium hydroxide to deionized water at 5°C respectively to form an aqueous solution of zinc acetate and an aqueous solution of sodium hydroxide with initial concentrations of 1 mol / L and 4 mol / L respectively;

[0025] b) Take 20mL of the above-mentioned aqueous solution of zinc acetate, slowly add it dropwise to 30mL of the above-mentioned aqueous solution of sodium hydroxide, stir until the mixed solution is completely clear, and obtain Zn(OH) with a molar concentration of 0.4mol / L 4 2- aqueous solution;

[0026] c) the above Zn(OH) 4 2- Quickly pour 50mL of the aqueous solution into 500mL of deionized water at room temperature (25°C), and stir for precipitation reaction for 30 minutes;

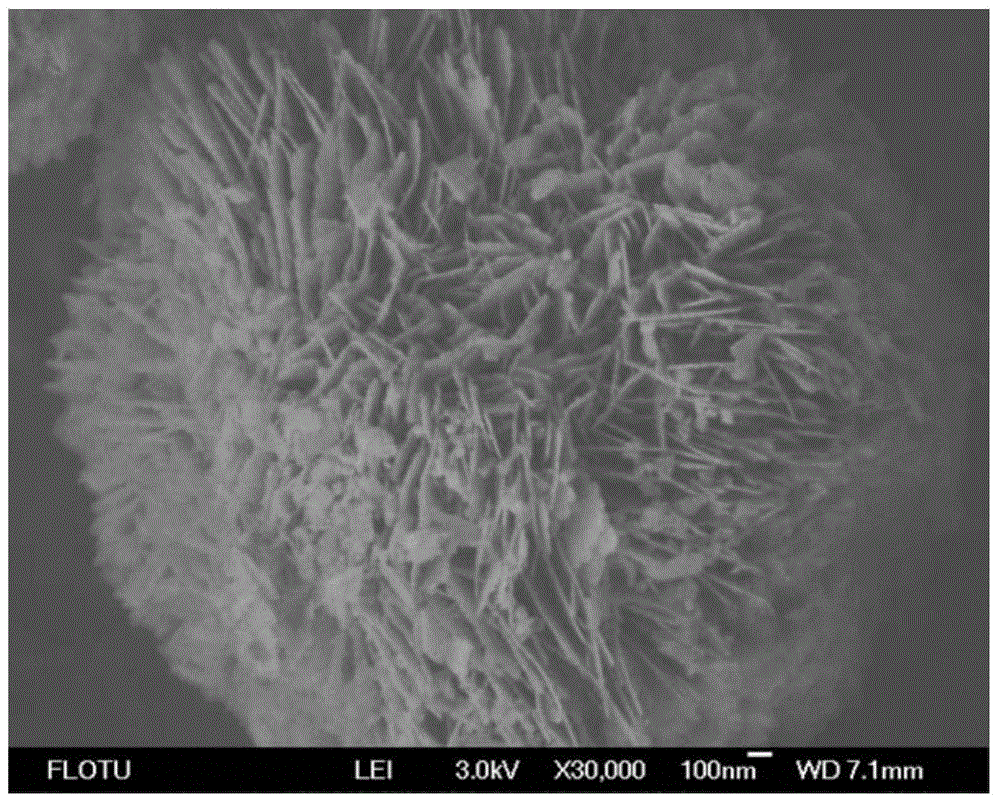

[0027] d) Suction filter the obtained suspension, wash the product twice with deionized water and once with ethanol, and dry to obtain a white powder, which is the zinc oxide nanosheet cluster provided by the present invention, with a ...

Embodiment 2

[0039] According to the steps of Example 1, only the deionized water at normal temperature (25° C.) in step c was replaced with deionized water at 50° C. to obtain the zinc oxide nanosheet clusters provided by the present invention with a yield of 85%.

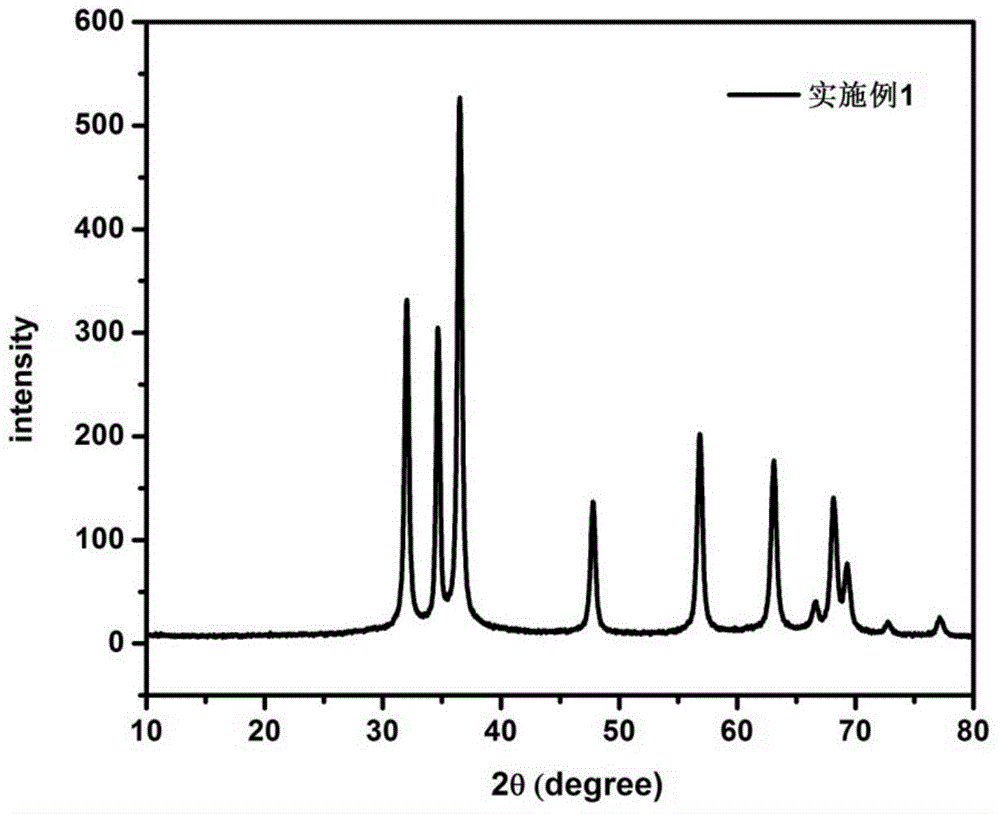

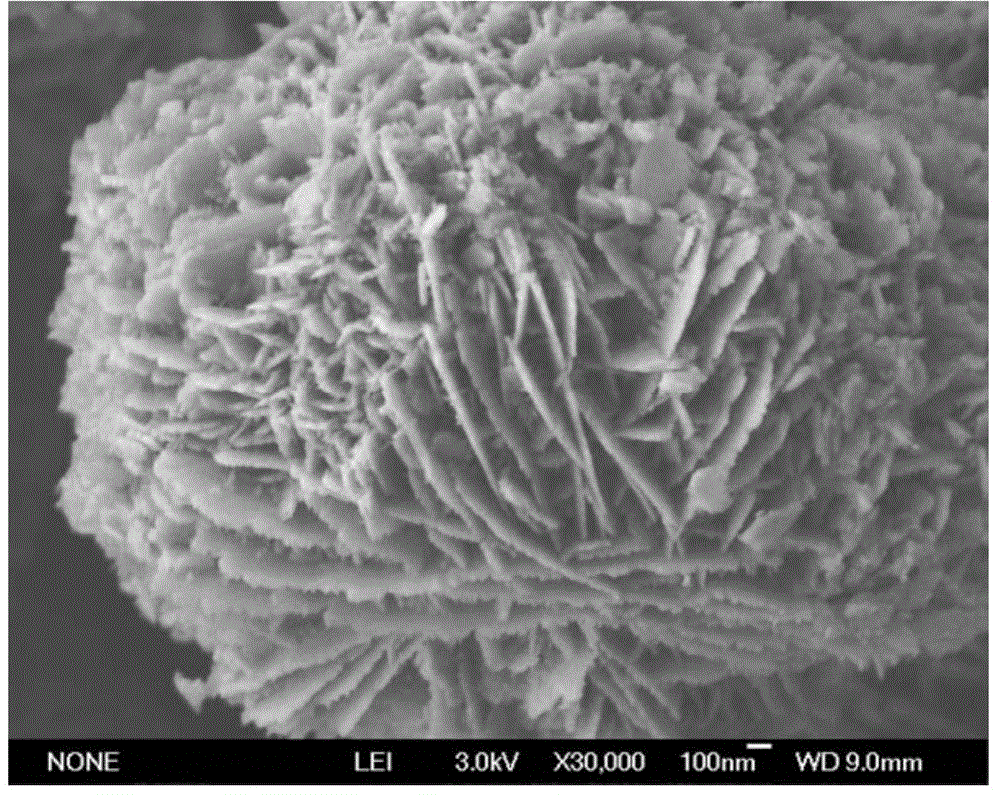

[0040] The scanning electron microscope results and XRD results of the resulting zinc oxide nanosheet clusters are shown in image 3 and 4 .

[0041] It can be seen from the figure that after increasing the reaction temperature, the size of the zinc oxide nanosheet clusters does not change greatly, but the zinc oxide sheets on the nanometer scale become slender compared to Example 1, and the nanosheet clusters are denser, and the nanosheet clusters has a diameter of 6 μm and consists of nanosheets with a thickness of 100 nm.

[0042] XRD results showed that the obtained product was still pure nano zinc oxide.

[0043] According to the method of Example 1, the photoelectric conversion efficiency of the dye-sensitized solar c...

Embodiment 3

[0045] According to the steps of Example 1, only sodium hydroxide in step a) was replaced with potassium hydroxide to obtain the zinc oxide nanosheet clusters provided by the present invention with a yield of 83%.

[0046] The scanning electron microscopy results of the resulting zinc oxide nanosheet clusters are shown in Figure 5 .

[0047] It can be seen from the figure that the product obtained in this example is basically the same as that in Example 1, and the use of different alkaline precursors has little effect on the morphology and composition of the product.

[0048]According to the method of Example 1, the photoelectric conversion efficiency of the dye-sensitized solar cell prepared by using the nano-zinc oxide obtained in this example is 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com