High thermal conductivity flame-retardant nylon composite material and preparation method thereof

A technology of flame-retardant nylon and composite materials, which is applied in the field of high thermal conductivity flame-retardant nylon composite materials and its preparation, can solve problems such as poor dispersion and thermal conductivity, excessive filling, and complicated procedures, and achieve low density and high phase density. Effects of capacitive, easy dispersion and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

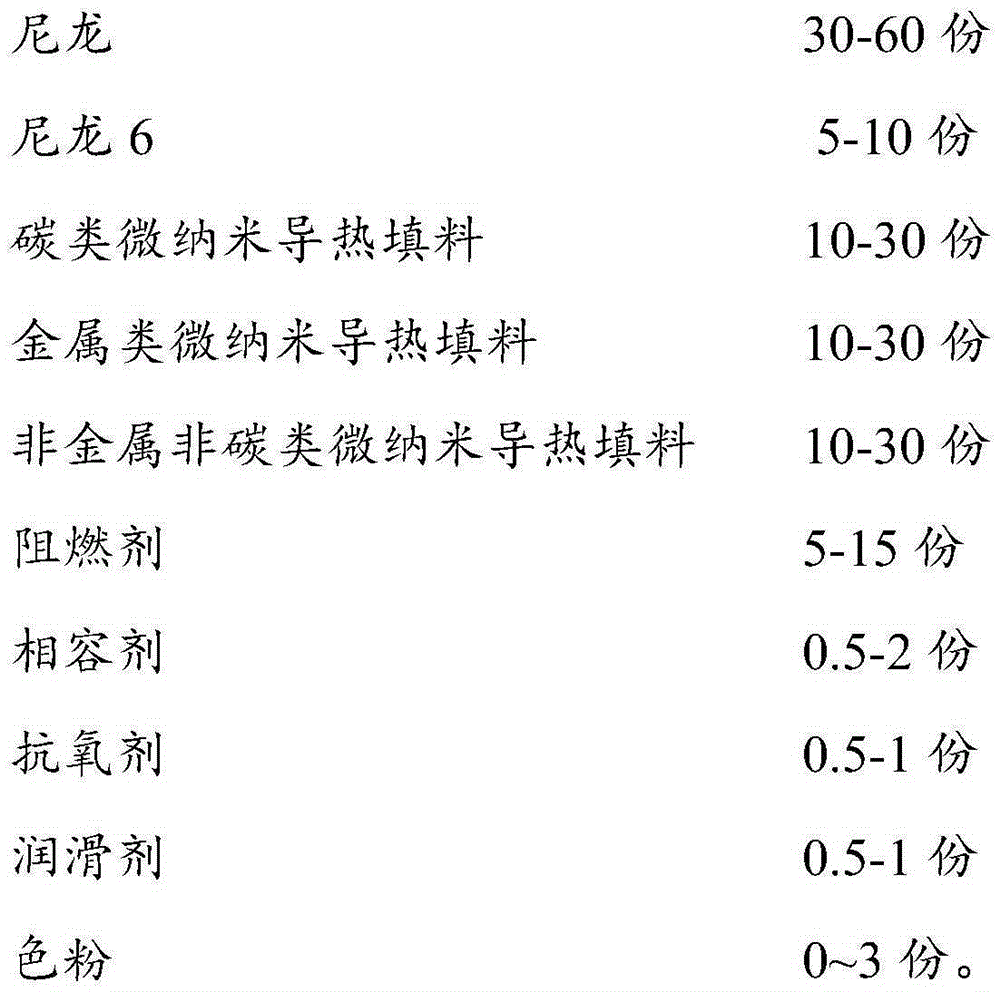

[0039] Correspondingly, on the basis of the high thermal conductivity and flame retardant nylon composite material described above, the embodiment of the present invention also provides a preparation method of the high thermal conductivity and flame retardant nylon composite material. In one embodiment, the preparation method of the high thermal conductivity flame-retardant nylon composite material comprises the following steps:

[0040] Step S01: Weigh the raw materials of each component according to the components of the high thermal conductivity and flame-retardant nylon composite material of the embodiment of the present invention described above;

[0041] Step S02: Mix the carbon-based micro-nano thermally conductive filler, metal-based micro-nano thermally-conductive filler, non-metallic non-carbon micro-nano thermally-conductive filler and compatibilizer weighed in step S01 at 80-150°C for 1-10min, and then add For nylon 6, heat up to 215-230°C and mix for 1-10 minutes ...

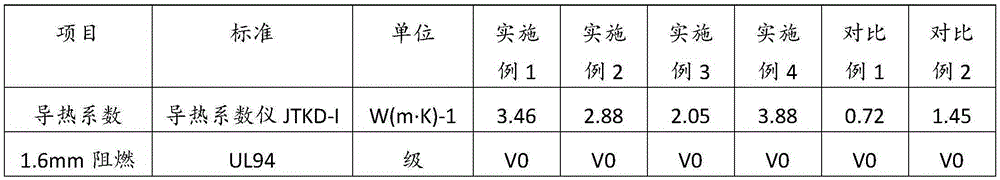

Embodiment 1

[0052] A high thermal conductivity flame retardant nylon composite material and a preparation method thereof, the high thermal conductivity flame retardant nylon composite material is prepared according to the following method:

[0053] S11: Mix 5KG flake graphite, 30KG silver-plated attapulgite (the mass ratio of silver to attapulgite is 0.3), 30KG aluminum nitride fiber and 2KG aluminate coupling agent at 80°C for 10min, then add 10KG nylon 6 powder, Raise the temperature to 215 and mix for 10 minutes to obtain the first mixture;

[0054] S12: Mix the first mixture with 30KG nylon 6 powder, 3.5KG decabromodiphenylethane, 1.5KG antimony trioxide, 0.5KG antioxidant 1098, 0.5KG antioxidant 627, 1KG lubricant silicone powder and color powder mixed to obtain a second mixture;

[0055] S13: The second mixture is melt-extruded at 230-250° C., drawn, water-cooled and pelletized to obtain high thermal conductivity and flame-retardant micro-nano nylon.

Embodiment 2

[0057] A high thermal conductivity flame retardant nylon composite material and a preparation method thereof, the high thermal conductivity flame retardant nylon composite material is prepared according to the following method:

[0058] S21: Mix 30KG expanded graphite, 10KG copper-coated mica powder (the mass ratio of copper to mica powder is 10), 10KG silicon nitride whiskers and 0.5KG stearic acid at 150°C for 1min, then add 5KG nylon 6 powder, and heat up to Mix at 230°C for 1 min to obtain the first mixture;

[0059] S22: Mix the first mixture with 60KG nylon 9T powder, 12KG brominated polystyrene, 3KG antimony trioxide, 0.1KG antioxidant 1010, 0.1KG antioxidant 168, 0.1KG lubricant PETS and toner to obtain the second mixture;

[0060] S23: The second mixture is melt-extruded at 260-300°C, drawn, water-cooled and pelletized to obtain a high thermal conductivity flame-retardant micro-nano nylon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com