Gridless AlGaN/GaN field effect transistor sensor, and preparation method thereof

A field effect transistor and sensor technology, applied in the field of gateless AlGaN/GaN field effect transistor sensor and its preparation, can solve the problems of difficulty in identification of pollutants, difficulty in detection of pollutants, etc., and achieves improved selective adsorption, convenient and rapid reuse , the effect of high-precision quantitative detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Realization of Po 4 3- ion detection as an example.

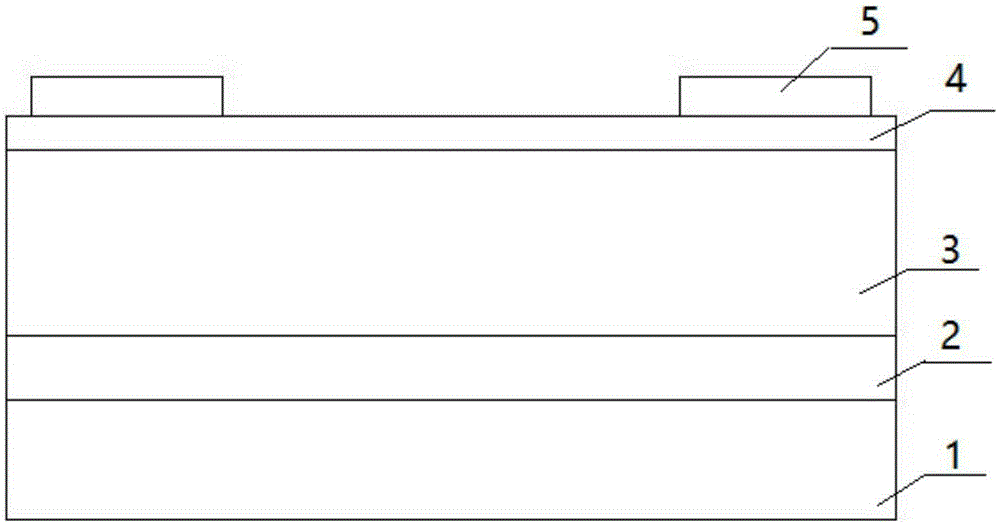

[0046] (1) First, the preparation steps of AlGaN / GaN heterojunction materials:

[0047] 1. A thin AlN nucleation layer of 22nm is grown on the SiC substrate 1;

[0048] 2. Then grow a thick GaN buffer layer of 32um;

[0049] 3. Finally, a 25nm AlGaN barrier layer 4 is grown, and the Al composition of the AlGaN thin film is 0.3.

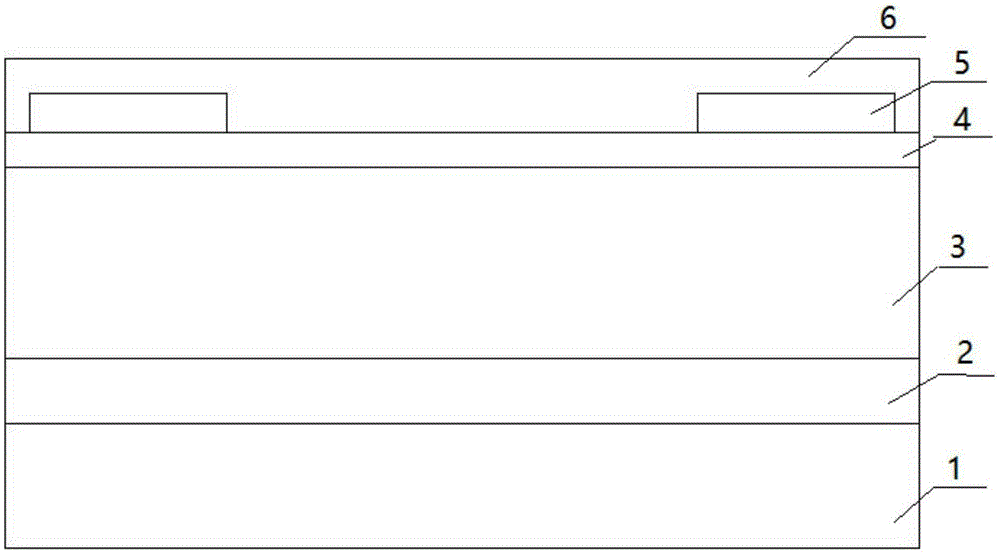

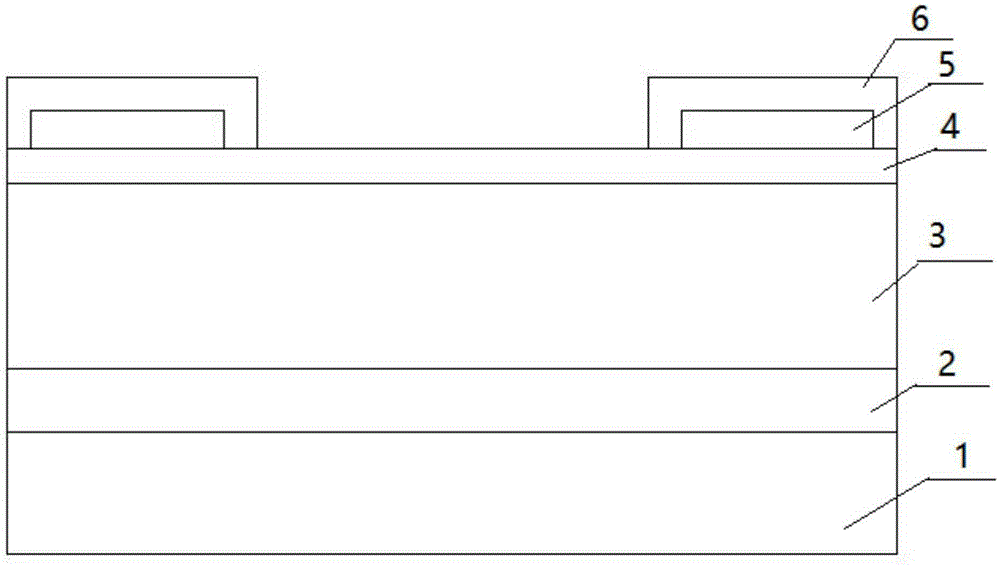

[0050] The second is the preparation process steps of AlGaN / GaN field effect transistor sensor:

[0051] (2) substrate cleaning, first with 50% hydrochloric acid, 50% KOH each treatment for 10 minutes, remove the oxide layer on the surface, rinse repeatedly with deionized water, acetone, alcohol, deionized water in order to ultrasonic 10 minutes;

[0052] (3) Ohmic contact electrodes, on the cleaned AlGaN / GaN heterogeneous crystal sheet, use electron beam evaporation technology to deposit the source electrode 51, the source electrode PAD52 connected to the source electrode, the drain el...

Embodiment 2

[0073] AlGaN / GaN field-effect transistor sensors prepared on sapphire substrate 3 CCOO - ion detection as an example.

[0074] 1. First, the preparation steps of AlGaN / GaN heterojunction materials:

[0075] Method is with embodiment 1. the difference lies in:

[0076] 1. Grow a thin AlN nucleation layer of 1nm on a sapphire substrate;

[0077] 2. Then grow a thick GaN buffer layer 1um;

[0078] 3. Finally, a 15nm AlGaN barrier layer is grown, and the Al composition of the AlGaN film is 0.2.

[0079] Second, the second is the preparation process steps of AlGaN / GaN field effect transistor sensor:

[0080] 1. Substrate cleaning; 2. Ohmic contact electrodes; 3. Making SiO 2 Passivation layer, passivation method is with embodiment 1;

[0081] 4. The surface of the gate-free area is functionalized. Firstly, the gate-free area is oxidized by inductively coupled plasma etching (ICP); 2 Blow dry; then put the substrate into r-aminopropyltrimethoxysilane (AMPS) aqueous solution...

Embodiment 3

[0094] Realization of Cr 2 o 4 2- ion detection as an example.

[0095] 1. First, the preparation steps of AlGaN / GaN heterojunction materials:

[0096] Method is with embodiment 1. the difference lies in:

[0097] 1. Growth of a thin AlN nucleation layer of 3nm on a SiC substrate;

[0098] 2. Then grow a thick GaN buffer layer of 3um;

[0099] 3. Finally, a 20nm AlGaN barrier layer is grown, and the Al composition of the AlGaN film is 0.22.

[0100] Second, the second is the preparation process steps of AlGaN / GaN field effect transistor sensor:

[0101] 1. substrate cleaning; 2. ohmic contact electrode; 3. passivation method with embodiment 1

[0102] 4. The surface of the gate-free area is functionalized. Firstly, the gate-free area is oxidized by inductively coupled plasma etching (ICP); 2 Blow dry; then put the substrate into r-aminopropyltrimethoxysilane (AMPS) aqueous solution (V AMPS :V H2O =1:10) React at 50°C for 24h, put it in a vacuum oven and dry at 120°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com