Sorghum and quinoa multi-grain bread and processing method thereof

A technology of sorghum quinoa and miscellaneous grains, applied in dough preparation, dough processing, pre-baked dough processing, etc., can solve the problems of weakening the gluten protein quality in the mixed flour, time-consuming and labor-intensive fermentation of miscellaneous grain bread, and failure to achieve nutritional balance. Increase antioxidant effect, increase health value, prevent aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

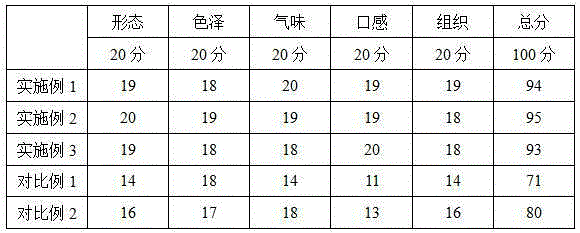

Embodiment 1

[0030] A sorghum quinoa multigrain bread, the preparation process is as follows:

[0031] 20 parts of whole sorghum flour, 10 parts of whole quinoa flour, 50 parts of high-gluten wheat flour, 0.8 parts of dry yeast, 2 parts of butter, 3 parts of skimmed milk powder, 0.3 parts of bread improver, 6 parts of egg liquid, 10 parts of milk, 0.6 parts of salt 2 parts of white sugar, 28 parts of water, 2 parts of beer;

[0032] (1) Preparation of whole sorghum flour: Sorghum is selected, screened, impurity-removed, cleaned, dried in a constant temperature drying oven at 60°C, and then crushed through a 100-mesh sieve to obtain whole sorghum flour; rough sorghum Add water to the whole powder to adjust the water content to 26%, then use a twin-screw extruder to extrude in four stages. min, the screw speed is set to 200r / min to produce extruded material, which is ultrafinely pulverized to 400 mesh to obtain whole sorghum flour;

[0033] (2) Preparation of whole quinoa powder: select, s...

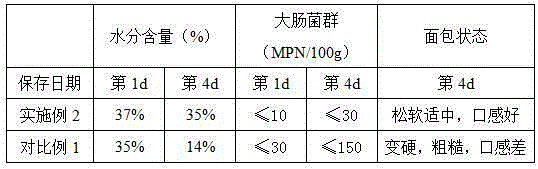

Embodiment 2

[0042] A sorghum quinoa multigrain bread, the preparation process is as follows:

[0043] 26 parts of whole sorghum flour, 20 parts of whole quinoa flour, 60 parts of high-gluten wheat flour, 0.9 parts of dry yeast, 3 parts of butter, 4 parts of skimmed milk powder, 0.4 parts of bread improver, 8 parts of egg liquid, 14 parts of milk, 0.7 parts of salt 3 parts of white sugar, 30 parts of water, 2 parts of beer;

[0044] (1) Preparation of whole sorghum flour: Sorghum is selected, screened, impurity-removed, cleaned, dried in a constant temperature drying oven at 60°C, and then crushed through a 100-mesh sieve to obtain whole sorghum flour; rough sorghum Add water to the whole powder to adjust the water content to 30%, and then use a twin-screw extruder to extrude in four stages. The extrusion temperatures of the four stages are 60°C, 90°C, 110°C, and 150°C respectively, and the feeding speed is 400g / min, the screw speed is set to 300r / min to obtain puffed material, and the p...

Embodiment 3

[0051] A sorghum quinoa multigrain bread, the preparation process is as follows:

[0052] 30 parts of whole sorghum flour, 17 parts of whole quinoa flour, 70 parts of high-gluten wheat flour, 1.2 parts of dry yeast, 4 parts of butter, 2 parts of skimmed milk powder, 0.5 parts of bread improver, 4 parts of egg liquid, 20 parts of milk, 0.8 parts of salt 4 parts of white sugar, 25 parts of water, 3 parts of beer;

[0053] (1) Preparation of whole sorghum flour: same as Example 2;

[0054] (2) Preparation of quinoa whole powder: same as Example 2;

[0055] (3) Preparation of liquid seed: Dissolve 1.2 parts of dry yeast in 1% kojic acid aqueous solution at 30°C to prepare a yeast solution, place it in a constant temperature incubator for activation, and activate it for 20 minutes at a temperature of 30°C; Take 50 parts of high-gluten wheat flour and 4 parts of white sugar, stir and mix evenly, then add 15 parts of water and activated yeast solution, mix well and make it into a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com