Carbon dioxide base waterborne polyurethane, carbon dioxide base waterborne polyurethane coating and preparation method thereof

A technology of water-based polyurethane and carbon dioxide, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of hard coating film and high glass transition temperature, and achieve good oxidation resistance and hydrolysis resistance properties, low glass transition temperature, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

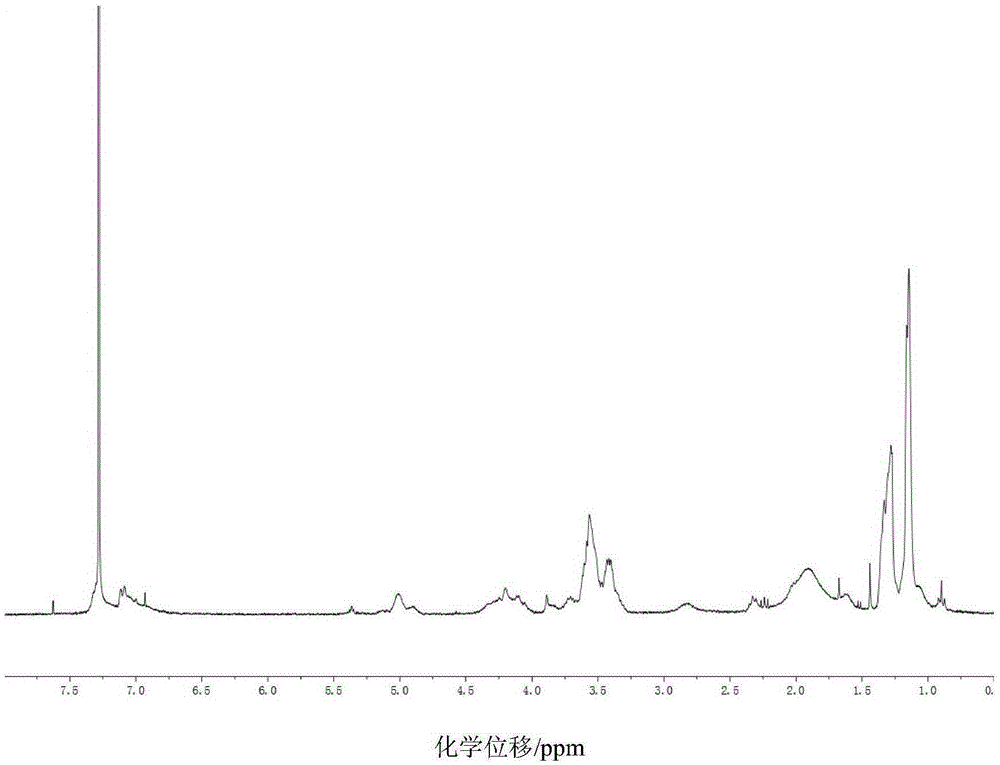

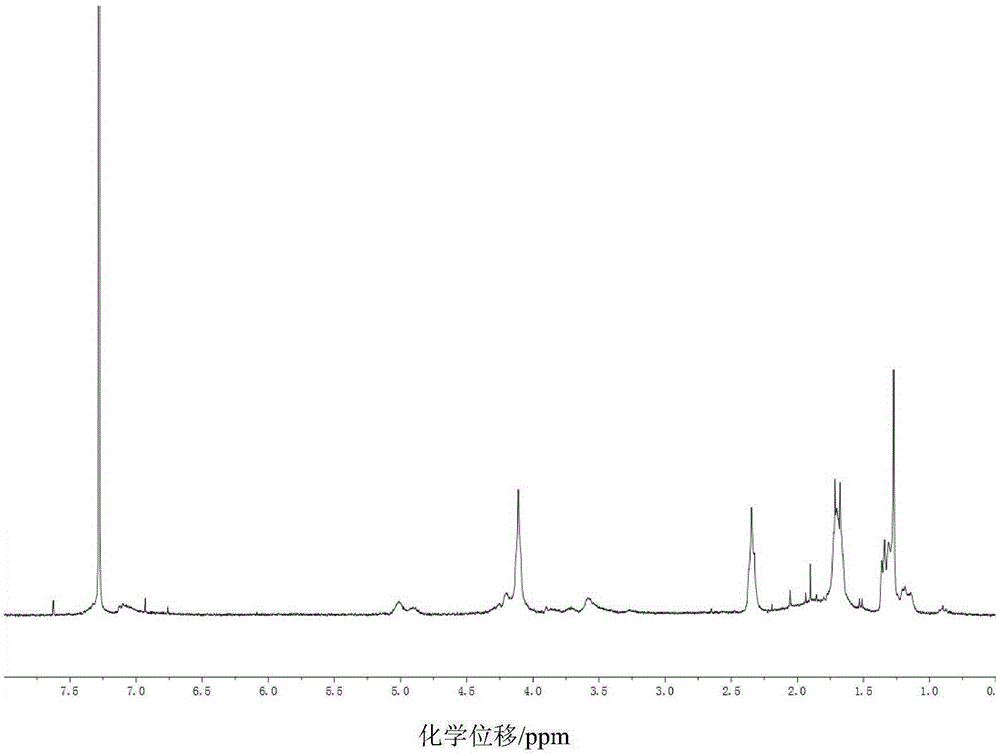

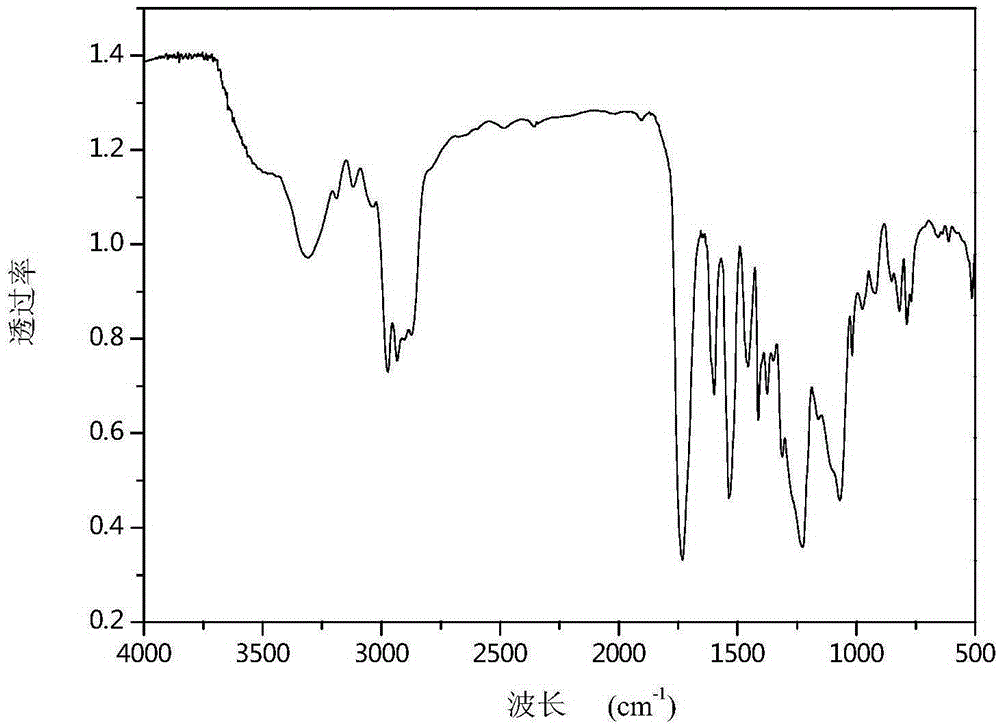

[0084] combine figure 1 and image 3 Illustrative Example 1

[0085] Preparation of carbon dioxide-based water-based polyurethane with formula I structure:

[0086] (1) Under nitrogen protection, 200g poly(carbonate-ether) glycol (number-average molecular weight: 1500 Dalton) and 270g polypropylene glycol (number-average molecular weight: 2000 Dalton) are added in the reactor, and the temperature is raised to 100°C, after vacuum distillation for 3 hours, lower the temperature to 80°C, dissolve 150g of diphenylmethane diisocyanate in 150g of butanone, drop it into the reactor at a speed of 12ml / min, and polymerize for 2.5h to obtain the first prepolymer;

[0087] (2) Dissolve 80g of 2,2-dimethylolpropionic acid and 0.4g of dibutyltin dilaurate in 250g of methyl ethyl ketone, add it to the reaction kettle, and continue the reaction for 4 hours to obtain the second OH-terminated prepolymer;

[0088] (3) Dissolve 100g of diphenylmethane diisocyanate in 340g of methyl ethyl keton...

Embodiment 2

[0095] Preparation of carbon dioxide-based water-based polyurethane with formula I structure:

[0096] (1) Under nitrogen protection, add 680g poly(carbonate-ether) diol (number average molecular weight: 3400 Dalton) and 600g polytetrahydrofuran diol (number average molecular weight: 3000 Dalton) into the reactor , raised the temperature to 100°C, distilled under reduced pressure for 3 hours, then lowered the temperature to 80°C, dissolved 160g of dicyclohexylmethane diisocyanate in 160g of methyl ethyl ketone, dropped it into the reactor at a speed of 10ml / min, and polymerized for 2.5h to obtain the terminal a first prepolymer with NCO;

[0097] (2) 90g of 2,2-dimethylolbutyric acid and 0.5g of dibutyltin dilaurate were dissolved in 280g of butanone, added to the reaction kettle, and the reaction was continued for 4 hours to obtain the second OH-terminated prepolymer;

[0098] (3) Dissolve 110g of dicyclohexylmethane diisocyanate in 320g of butanone, drop it into the reactor...

Embodiment 3

[0104] Preparation of carbon dioxide-based water-based polyurethane with formula I structure:

[0105] (1) Under the protection of nitrogen, 720g poly(carbonate-ether) diol (number average molecular weight: 6000 Dalton) and 560g polycaprolactone diol (number average molecular weight: 2000 Dalton) were added to the reaction In the kettle, heat up to 100°C, distill under reduced pressure for 3 hours, then cool down to 80°C, dissolve 100g of 1,6-hexamethylene diisocyanate in 200g of methyl ethyl ketone, drop it into the reaction kettle at a speed of 11ml / min, and continue to polymerize for 2 hours , to obtain the first prepolymer with NCO at the end;

[0106] (2) Dissolve 80g of 2,2-dimethylolpropionic acid and 0.6g of dibutyltin dilaurate in 310g of methyl ethyl ketone, add it to the reaction kettle, and continue the reaction for 2 hours to obtain the second OH-terminated prepolymer;

[0107] (3) Dissolve 70g of 1,6-hexamethylene diisocyanate in 280g of butanone, drop it into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com