Preparation method and application of nano Cu-organic complex/Ag composite

A technology of organic complexes and composite materials, which is applied in the field of preparation of nano-Cu-organic complexes/Ag composite materials, can solve the problems of energy consumption and time consumption in the preparation of composite materials, achieve good industrial application prospects, reduce costs, and reduce poisoning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Preparation of Ligand H 6 L

[0056] Ligand H 6 L is prepared by heating and reacting 5-aminoisophthalic acid and cyanuric chloride under alkaline conditions. The preparation steps are as follows:

[0057] Add 0.073mol of 5-aminoisophthalic acid, 0.117mol of sodium hydroxide and 0.085mol of sodium bicarbonate into 120mL of water; stir at room temperature for 30min, add 24mL of 1,4-cyanuric chloride containing 3.68g of cyanuric chloride dropwise within 5min Dioxane solution; heat the mixture to 100°C and continue to stir for 24 hours; after cooling to room temperature, neutralize the reaction solution to pH 5 with hydrochloric acid, filter with suction and wash with distilled water for 3 times, and dry to obtain the ligand H 6 L, the productive rate is 95%;

[0058] The ligand H 6 L, the construction formula is as follows:

[0059]

Embodiment 2

[0060] Example 2 Preparation of Cu-organic complex crystals by solvothermal method

[0061] 0.030g of H 6 L and 2 mL DMF, 2 mL DMSO and 100 μL H 2 O shaking and blending, adding 0.164g of Cu(NO 3 ) 2 ·3H 2 O After shaking and blending, add 0.9mL HBF 4 , the mixed solution was sealed in a reaction kettle, heated at 85°C for 3 days, and after natural cooling, the product was centrifuged and washed three times with anhydrous EtOH to obtain blue Cu-organic complex crystals, which were observed under a scanning electron microscope as regular octagonal crystals. Hedral crystal, the average particle size is about 20um;

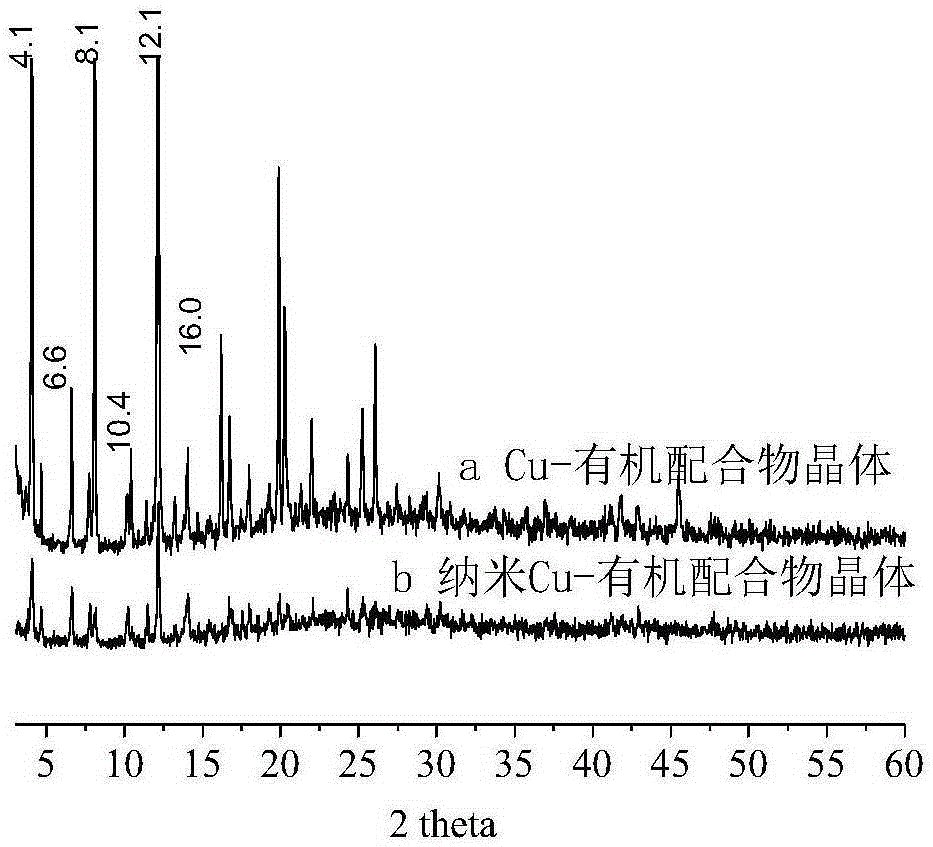

[0062] Single crystal diffraction analysis shows that the Cu-organic complex crystal has the chemical formula [Cu 3 L(H 2 O) 3 ]·10H 2 O·5DMF is a 3D porous metal-organic framework, one of which consists of three Cu 2+ , a L 6- , three H 2 O molecular composition; its XRD pattern as attached figure 1 As shown, its 2θ has characteristic absorption at 4.1,...

Embodiment 3

[0063] Embodiment 3 A kind of preparation method of nanometer Cu-organic complex / Ag composite material

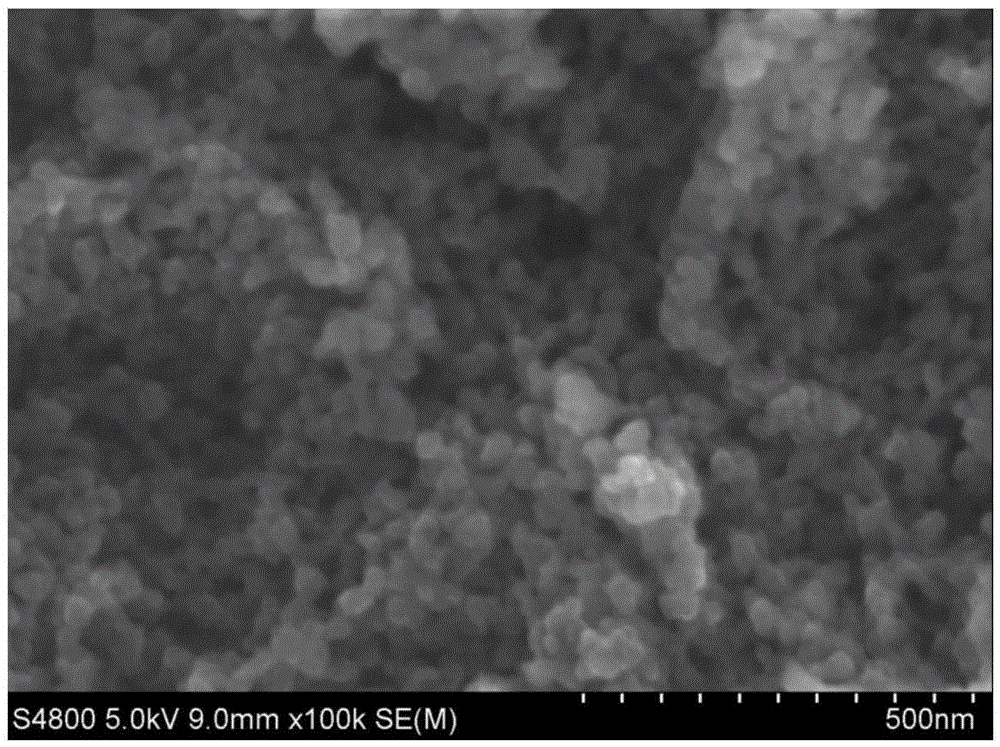

[0064] 0.17gCu(NO 3 ) 2 and 0.02g Ligand H 6 L was added to a mixed solvent of 0.4mL DMF and 0.4mL DMSO, and the two mixtures were blended and shaken for 6 seconds to obtain a Cu-organic complex gel; the Cu-organic complex gel was aged at 100°C 2 days, cooled to room temperature, washed 3 times with ethanol, dried to obtain nano Cu-organic complex crystals;

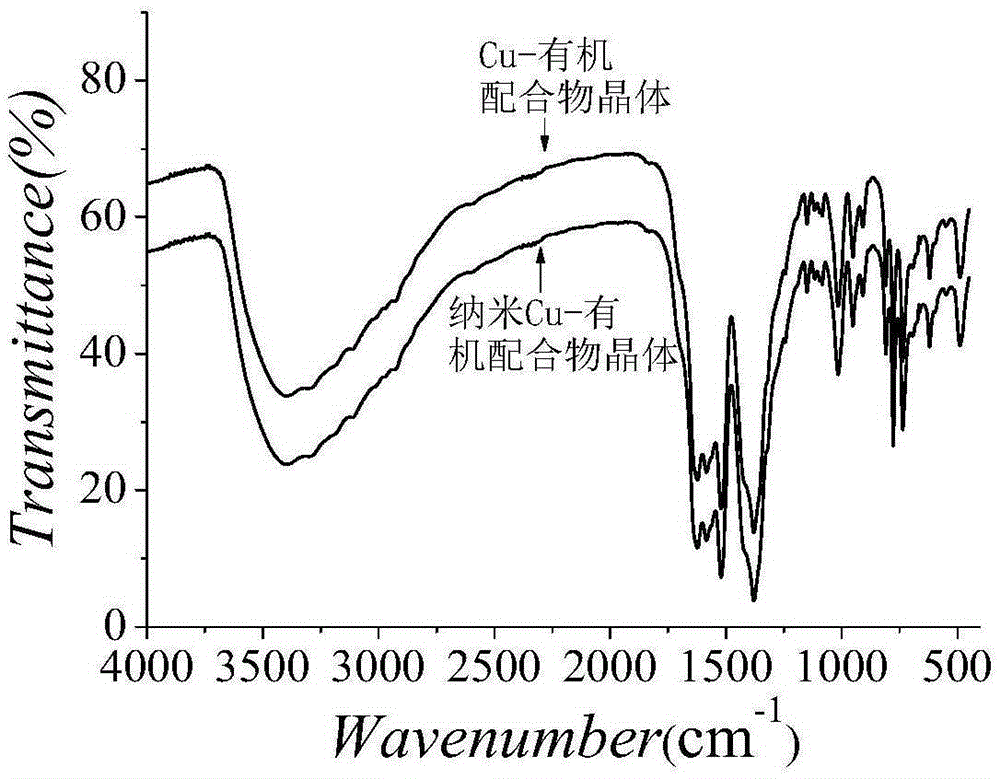

[0065] Described nanometer Cu-organic complex crystal, the XRD comparison of the Cu-organic complex crystal that obtains with solvent method sees attached figure 1 , the XRD pattern shows that the characteristic absorption peaks of the nano-Cu-organic complex crystal and the Cu-organic complex crystal prepared by the solvothermal method are the same, and 2θ has characteristic absorption at 4.1, 6.6, 81, 10.4, 12.1 and 16.0, This shows that the nano-Cu-organic complex crystal has the chemical formula [Cu 3 L(H 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com