Novel supersonic arc spray gun, spraying device and method for preparing fe-cr-ni composite coating

A technology of supersonic arc and spraying device, applied in spraying device, liquid spraying device, device for coating liquid on the surface, etc., can solve the problems of low hardness, poor wear resistance, etc. The effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

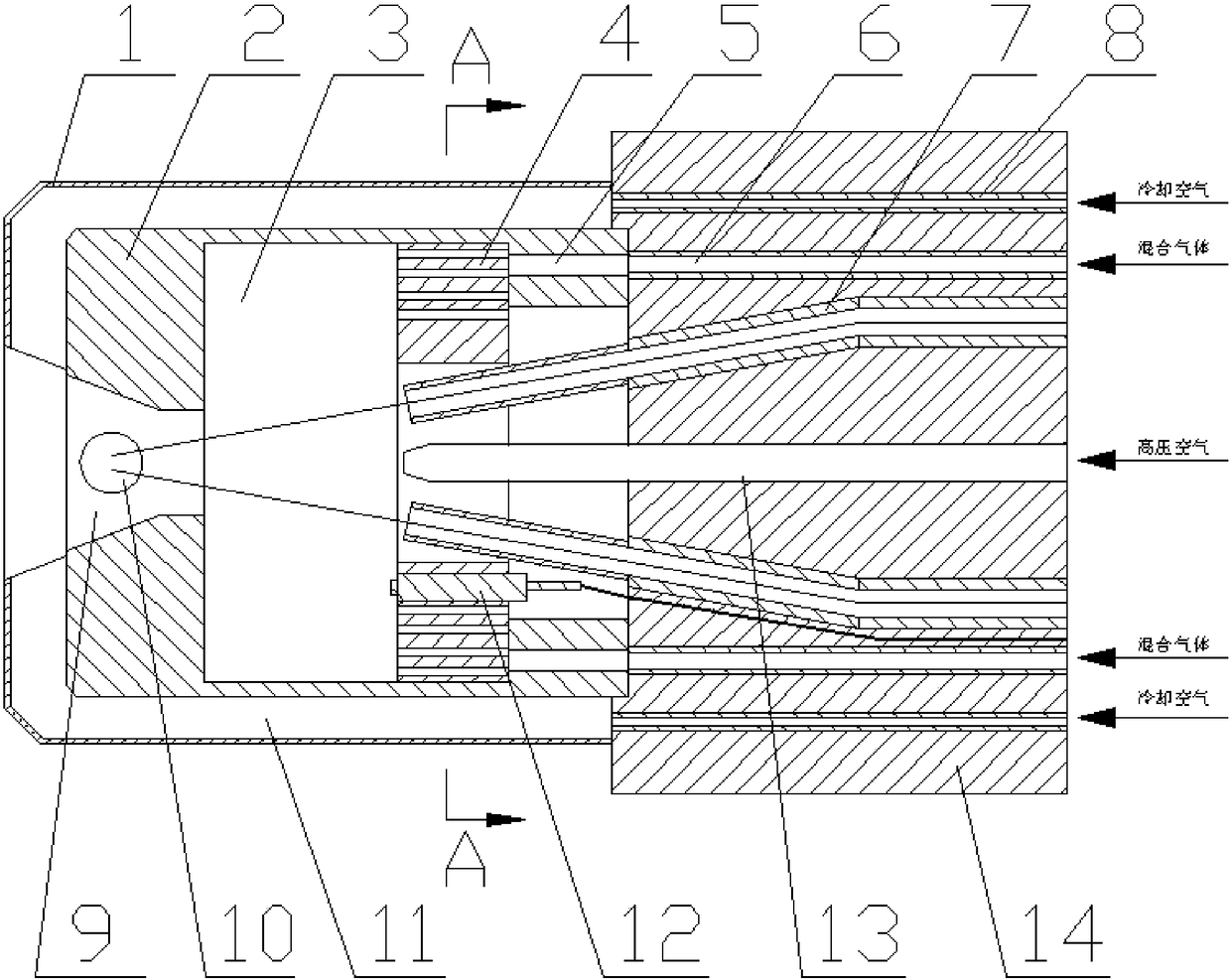

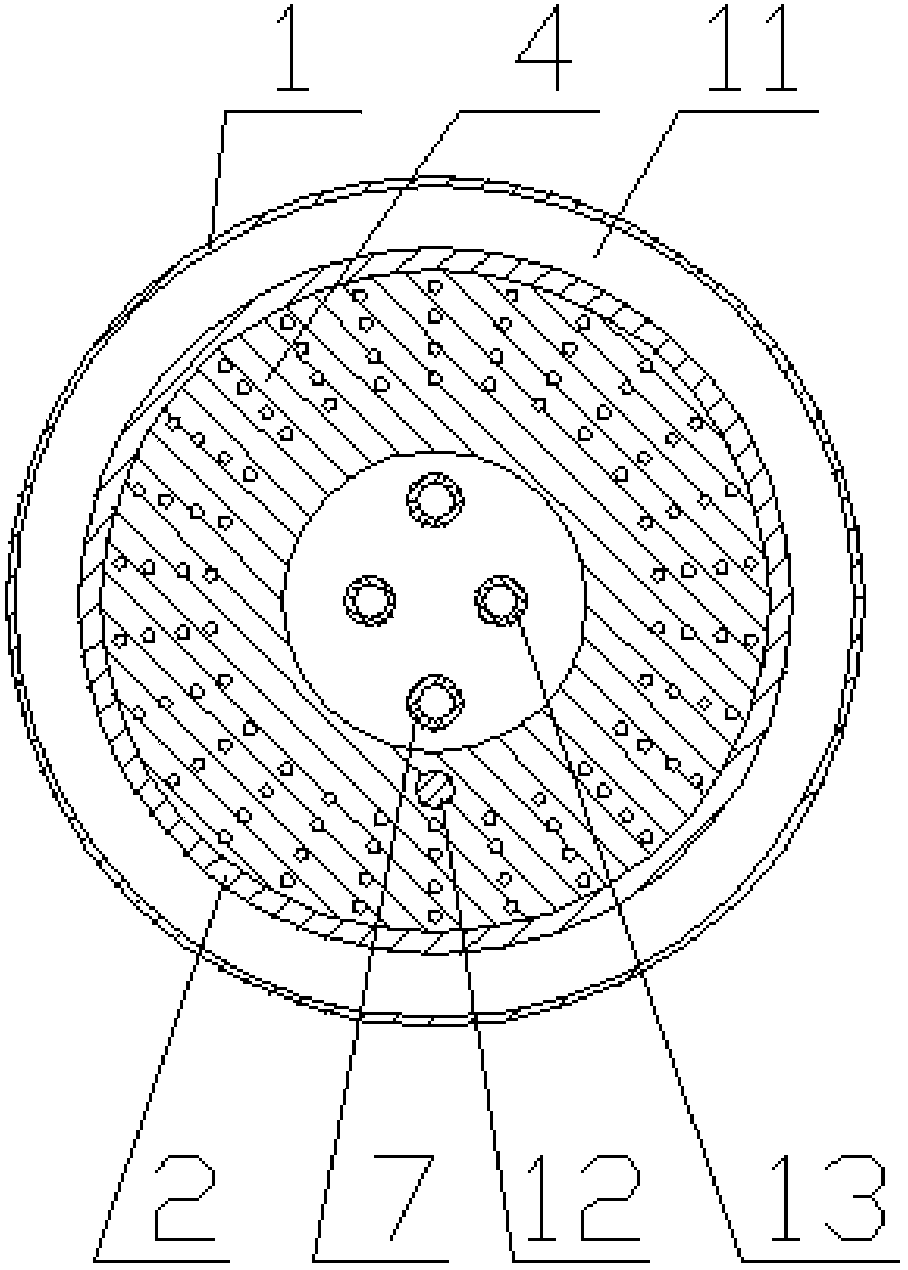

[0025] figure 1 Shown is an implementation case of the novel supersonic arc spray gun of the present invention, including two high-pressure air input pipes 13 and two guide wire pipes 7, and also includes an installation base 14, a combustion chamber housing 2, a protective housing 1 and The ignition device 12, the installation base 14 are provided with a cooling air pipe 8 and a mixed gas pipe 6 for feeding fuel and compressed air, and one end of the combustion chamber housing 2 is provided with 6 circular air intake holes 5 uniformly distributed , the other end has a trumpet-shaped atomizing nozzle 9, the combustion chamber housing 2 is fixedly connected with the installation base 14, a combustion chamber 3 is formed between the two, and a ring-shaped nozzle with several through holes is arranged in the combustion chamber 3. The catalytic ceramic sheet 4, the through hole on the upper part of the catalytic ceramic sheet 4 communicates with one end of the air inlet hole 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com