Copper zinc tin sulfur quantum dots and preparation method thereof

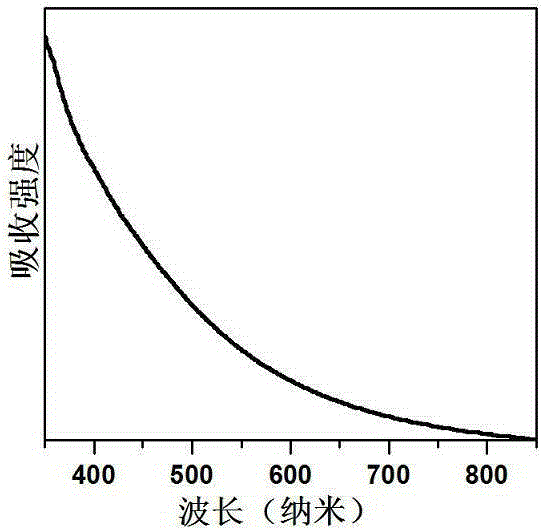

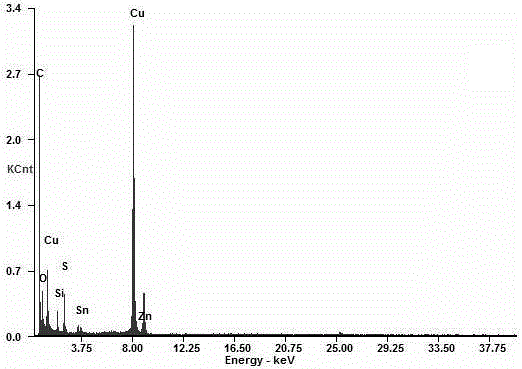

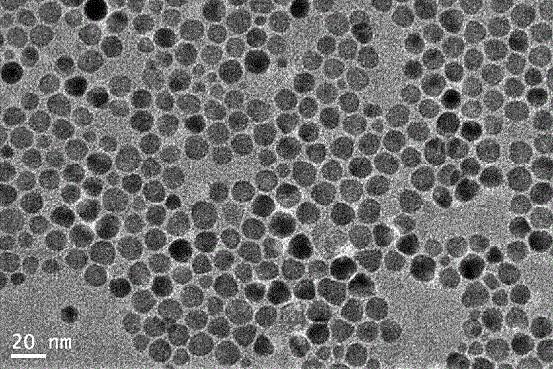

A technology of sulfur quantum and copper zinc tin is applied in the field of preparation of low-cost copper zinc tin sulfur quantum dots, which can solve problems such as the toxicity of quantum dots, and achieve the effect of improving repeatability, excellent properties and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: by atomic number, formula is as follows:

[0032] Chloroform 10000 parts

[0033] Methanol 5000 parts

[0034] Dodecylamine 750 parts

[0035] Fourteen mercaptan 500 parts

[0036] 2 parts copper sulfate

[0037] 1 part zinc nitrate

[0038] 1 part tin acetate

[0039] Preparation Process:

[0040] a. According to the number of atoms, 2 parts of copper sulfate, 1 part of zinc nitrate, 1 part of tin acetate, 500 parts of tetradecyl mercaptan, and 750 parts of dodecylamine were added to a three-necked flask at room temperature, Stir in the open system and heat to 180 degrees for 5 minutes;

[0041] b. the solution obtained in step a is cooled to 60 degrees, and 5000 parts of chloroform and 5000 parts of methanol are added to obtain a cloudy solution;

[0042] c. Centrifuge the turbid solution in step b for 10 minutes in a centrifuge, and add 5000 parts of chloroform to the obtained precipitate to obtain copper-zinc-tin-sulfur quantum dots dispersed i...

Embodiment 2

[0043] Embodiment 2: by atomic number, formula is as follows:

[0044] Dichloromethane 10000 parts

[0045] 5000 parts of ethanol

[0046] Octadecylamine 4125 parts

[0047] Dodecanethiol 2750 parts

[0048] 11 parts copper acetate

[0049] 5.5 parts of zinc nitrate

[0050] 5.5 parts of tin chloride

[0051] Preparation Process:

[0052] a. According to the number of atoms, add 11 parts of copper acetate, 5.5 parts of zinc nitrate, 5.5 parts of tin chloride, 2750 parts of dodecyl mercaptan, and 4125 parts of octadecylamine into a three-necked flask at room temperature , stirred in the open system and heated to 180 degrees for 5 minutes.

[0053] b. Cool the solution obtained in step a to 60°C, add 5000 parts of dichloromethane and 5000 parts of ethanol to obtain a cloudy solution.

[0054] c. Centrifuge the turbid solution in step b for 10 minutes in a centrifuge, and add 5000 parts of dichloromethane to the obtained precipitate to obtain copper-zinc-tin-sulfur quantu...

Embodiment 3

[0055] Embodiment 3: by the number of atoms, the formula is as follows:

[0056] Toluene 10000 parts

[0057] Acetone 5000 parts

[0058] Dodecylamine 7500 parts

[0059] Tetradecyl mercaptan 5000 parts

[0060] 20 parts copper nitrate

[0062] 10 parts tin nitrate

[0063] Preparation Process:

[0064] a. by number of atoms, 20 parts of copper nitrate, 10 parts of zinc sulfate, 10 parts of tin nitrate, 5000 parts of tetradecyl mercaptan, and 7500 parts of dodecylamine were added to a three-necked flask at room temperature, Stir in the open system and heat to 180 degrees for 5 minutes;

[0065] b. the solution obtained in step a is cooled to 60 degrees, and 5000 parts of toluene and 5000 parts of acetone are added to obtain a cloudy solution;

[0066] c. Centrifuge the turbid solution in step b for 10 minutes in a centrifuge, and add 5000 parts of toluene to the obtained precipitate to obtain copper-zinc-tin-sulfur quantum dots dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com