Organic fluorine-silicon surface treatment agent and preparation method thereof

A silicon surface and treatment agent technology, which is applied in the field of organofluorine silicon surface treatment agent and its preparation, can solve the problems of poor stability, low conversion rate, poor surface activity, etc., and achieve excellent high and low temperature resistance, oil resistance and solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

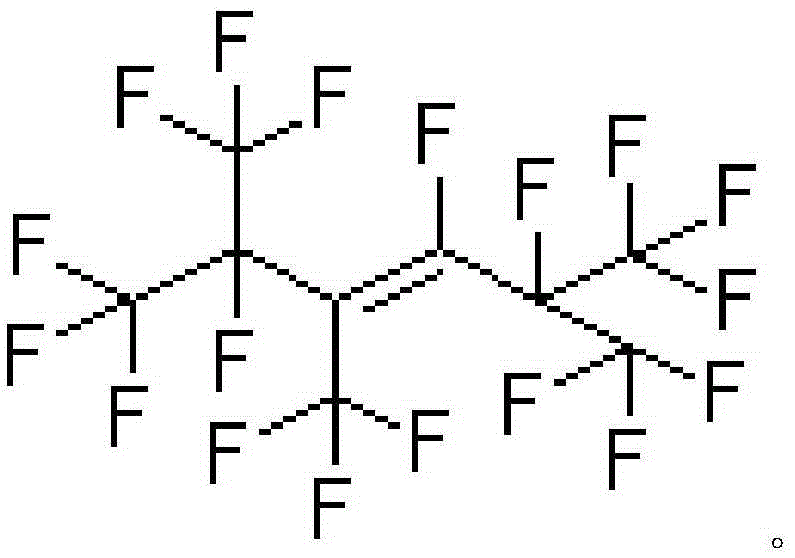

[0037] An organosilicon-fluorine surface treatment agent, which uses hexafluoropropylene trimer as a modifier, ethylene glycol dimethyl ether as a solvent, and triethylamine as a catalyst, through aminopropyltriethoxysilane -NH 2 The group undergoes a nucleophilic substitution reaction with the double-bond fluorine atom of the hexafluoropropylene trimer to synthesize a fluorosilicone compound as shown in the structural formula (VI).

[0038] (VI):

[0039] Concrete reaction steps are as follows:

[0040] Add 90ml of ethylene glycol dimethyl ether, 6.9g of triethylamine, and 30.6g of hexafluoropropylene trimer into the reaction bottle, stir evenly, raise the temperature to 30°C and add 17g of aminopropyltriethoxysilane dropwise, and dropwise The time is 50min, the dropwise addition is completed, and the temperature is raised to 60°C for 3h; after the reaction is completed, distill under reduced pressure at 0.1Mpa and 90°C for 2h to remove the solvent glycol dimethyl ether, ca...

Embodiment 2

[0042] An organosilicon fluorine surface treatment agent, which uses hexafluoropropylene trimer as a modifier, ethylene glycol dimethyl ether as a solvent, and triethylamine as a catalyst, through aminoethylaminopropylmethyl dimethyl -NH of oxysilane 2 The group undergoes a nucleophilic substitution reaction with the double-bond fluorine atom of the hexafluoropropylene trimer to synthesize a fluorosilicone compound as shown in structural formula (VII).

[0043] (Ⅶ):

[0044] Concrete reaction steps are as follows:

[0045] Add 100ml of ethylene glycol dimethyl ether, 6.9g of triethylamine, and 30.6g of hexafluoropropylene trimer to the reaction flask in sequence, stir evenly, raise the temperature to 30°C, and add aminoethylaminopropylmethyldimethoxy 14g of silane, the dropping time is controlled to be 50min. After the dropping is completed, the temperature is raised to 50°C for 3h; after the reaction is completed, vacuum distillation is carried out at 0.1Mpa and 90°C for ...

Embodiment 3

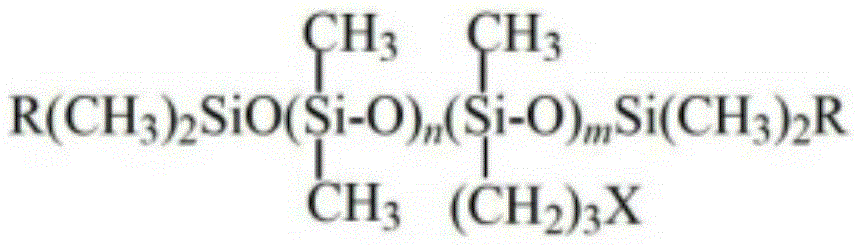

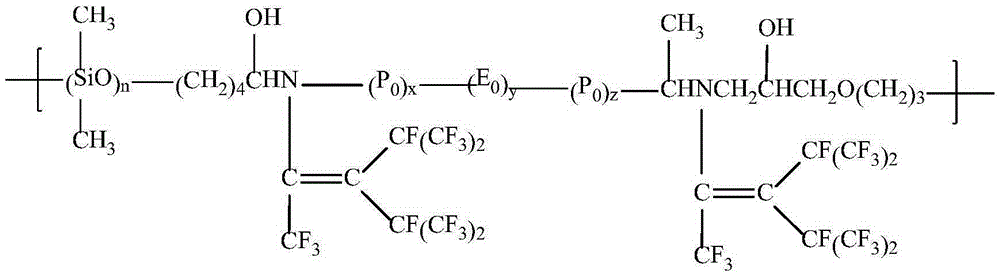

[0047] An organosilicon fluorine surface treatment agent, is that hexafluoropropylene trimer is used as a modifier, ethylene glycol dimethyl ether is used as a solvent, and triethylamine is used as a catalyst, and the general structural formula (Ⅲ) is -NH on the side chain amino silicone oil 2 The group reacts with the double bond fluorine atom of the hexafluoropropylene trimer to undergo a nucleophilic substitution reaction to synthesize a fluorosilicone polymer as shown in the general structural formula (Ⅷ).

[0048] (Ⅷ):

[0049] Concrete reaction steps are as follows:

[0050] Add 70ml of ethylene glycol dimethyl ether, 1.7g of triethylamine, and 40g of side chain amino silicone oil shown in formula (III) to the reaction flask in sequence, and stir under nitrogen protection, and add 7.4 g of hexafluoropropylene trimer dropwise at room temperature. g. Control the dropping time for 30 minutes. After the dropping, add 30ml of ethylene glycol dimethyl ether to maintain ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com