Microalgae culture system, cavity type photobioreactor and microalgae culture method

A technology for photobioreactor and microalgae cultivation, which is applied in the field of microalgae biology, can solve the problems of increased operating costs, high production and operation costs, and difficult construction, and achieves the goals of increasing stability and reducing production energy consumption and costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

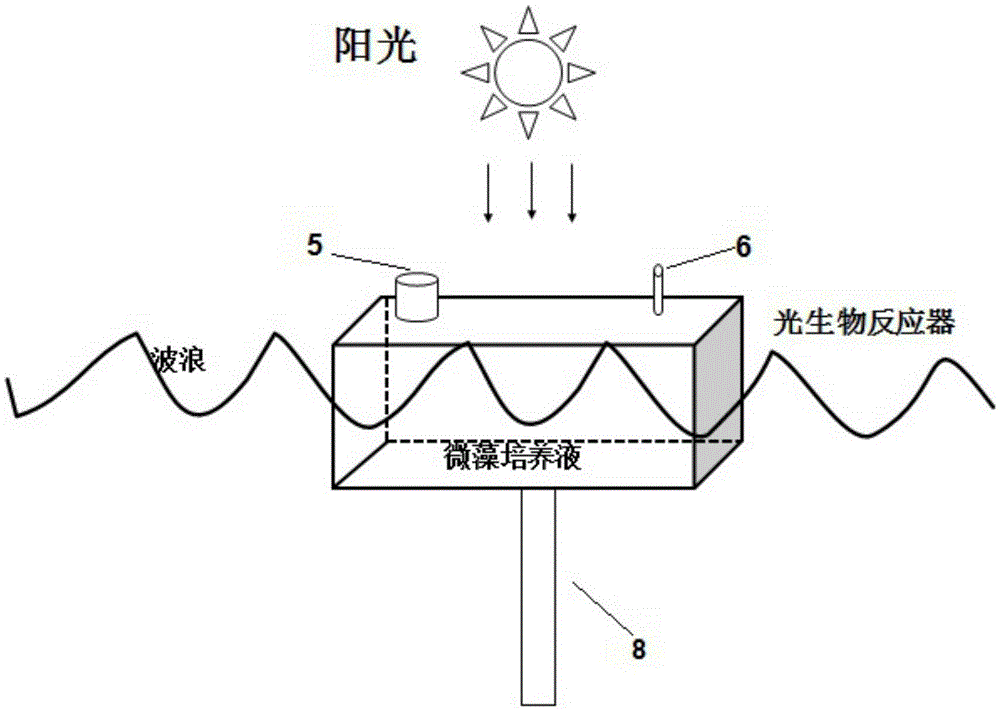

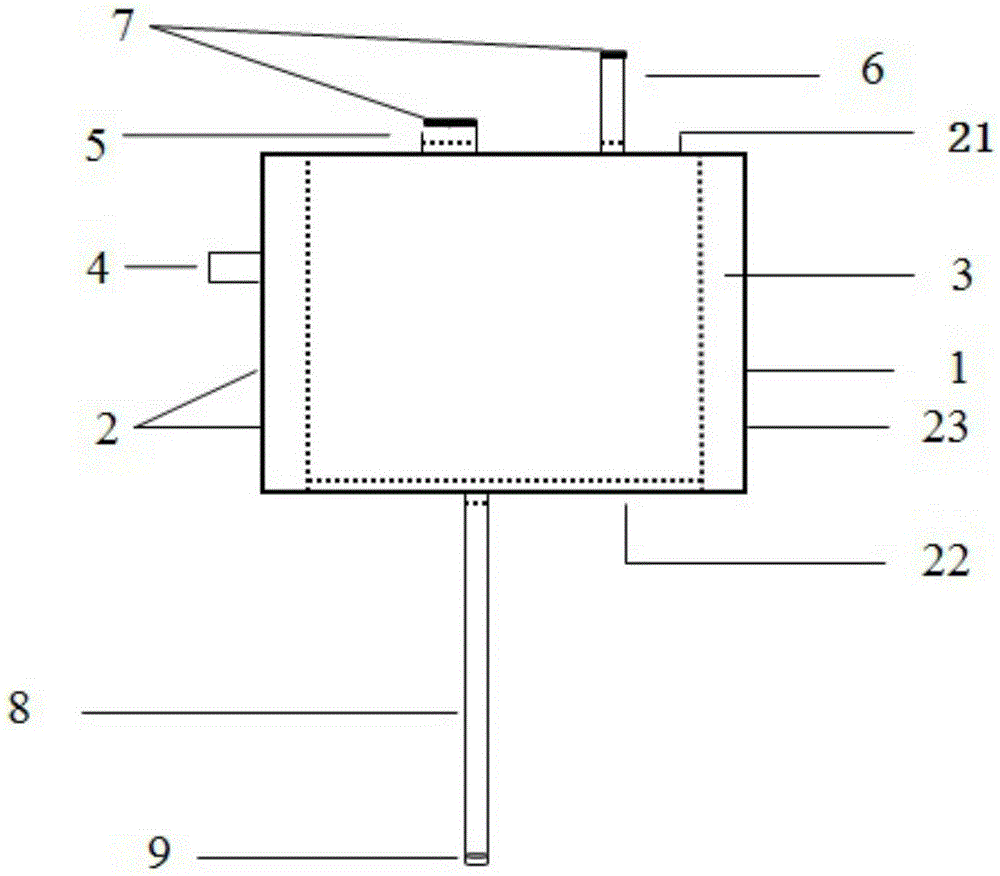

[0088] Embodiment 1 cavity type photobioreactor

[0089] Such as figure 1 , figure 2 As shown, the reactor includes a chamber body 1, the chamber wall 2 of the chamber body 1 is a sealed body with a hollow sandwich structure 3, and an air filling port 4 is provided on the outer layer of the hollow sandwich structure 3. The chamber wall 2 consists of the chamber body 1 consisting of an upper chamber wall 21 , a lower chamber wall 22 and a side chamber wall 23 .

[0090] The upper part of the cavity 1 is respectively provided with a material inlet and outlet 5 and a vent 6 , both of which pass through the cavity wall 2 and communicate with the inside of the cavity 1 . When in use, materials for cultivation, such as microalgae and microalgae culture fluid, are put in through the inlet and outlet 5, and during the cultivation process of the microalgae, samples are also taken through the inlet and outlet to observe the growth of the microalgae. Both the material inlet and outle...

Embodiment 2

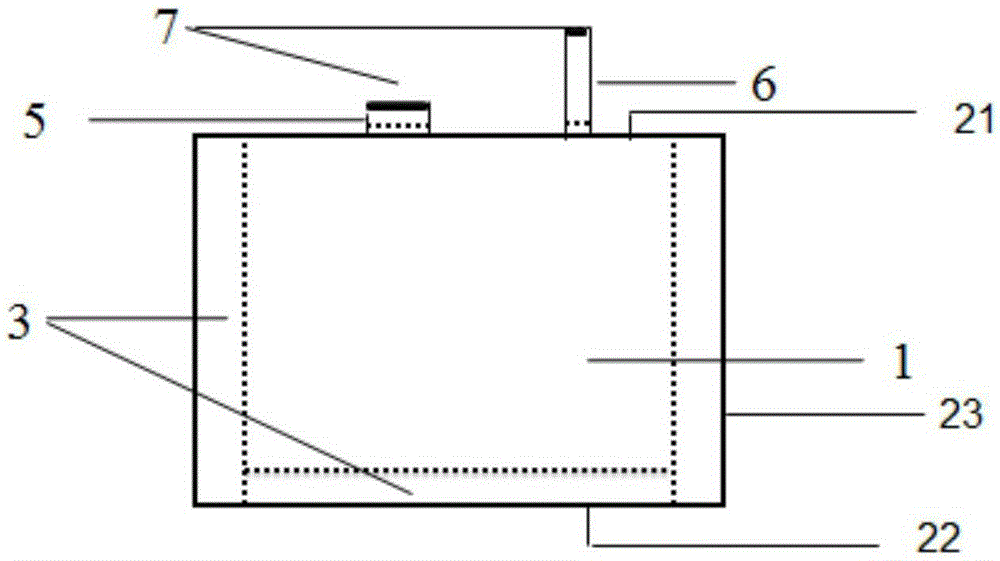

[0093] Embodiment 2 Rigid cavity type photobioreactor

[0094] Such as image 3 , Figure 4 As shown, the reactor includes a cavity body 1 , and the cavity wall 2 of the cavity body 1 is formed by bonding the cavity body 1 with an upper cavity wall 21 , a lower cavity wall 22 and a side cavity wall 23 . Both the side chamber wall 23 and the lower chamber wall 22 are sealed bodies with a hollow sandwich structure 3 . The upper part of the cavity 1 is respectively provided with a material inlet and outlet 5 and a vent 6 , both of which pass through the cavity wall 2 and communicate with the inside of the cavity 1 .

[0095] When in use, materials for cultivation, such as microalgae and microalgae culture fluid, are put in through the inlet and outlet 5, and during the cultivation process of the microalgae, samples are also taken through the inlet and outlet to observe the growth of the microalgae. Both the material inlet and outlet 5 and the air vent 6 are provided with an ai...

Embodiment 3

[0097] Embodiment 3 Flexible cavity type photobioreactor

[0098] Such as Figure 5 , Image 6 As shown, the reactor includes a cavity 1 , and the cavity wall 2 of the cavity 1 is composed of an upper cavity wall 21 , a lower cavity wall 22 and a side cavity wall 23 . The chamber wall 2 is a highly transparent polyvinyl chloride (PVC) film.

[0099] The side cavity wall 23 is a sealing body with a hollow interlayer structure 3. In the vertical direction, it is composed of three hollow sealing units I24. The hollow sealing units I24 are sealed and stacked. Each hollow sealing unit I is equipped with a And the inflation port 4 of deflation.

[0100] The upper cavity wall 21 is a sealing body with a hollow interlayer structure 3, and is composed of several hollow sealing units II 25 in the horizontal direction, and the hollow sealing units II 25 are sealed and connected. The upper part of the cavity 1 is respectively provided with a material inlet and outlet 5 and a vent 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com