Application of saccharomyces cerevisiae in biosynthetic L-phenylacetylcarbinol

A technology of phenylacetyl carbinol and Saccharomyces cerevisiae is applied in the field of bioengineering, which can solve the problems of complex process and high cost, and achieve the effects of simplified separation procedure, stable growth characteristics and high tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The acquisition of embodiment 1 benzaldehyde tolerant yeast strain

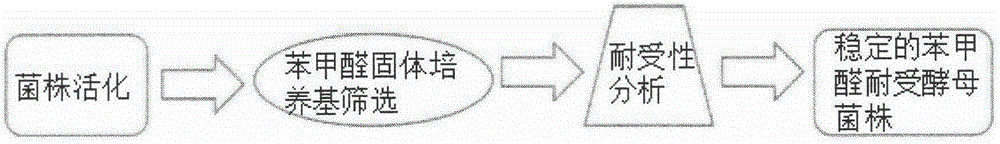

[0022] For the acquisition of benzaldehyde-tolerant yeast strains, see figure 1 ,Proceed as follows:

[0023] (1) Screening of benzaldehyde-resistant strains: Activate and pick a single colony for fermentation from commercially available yeast strains to obtain yeast cells; take 1 g of yeast cells and suspend them in 10 ml of normal saline, and take 50 μl of the cell fluid and inoculate them in 0.05 %, 0.1%, 0.2%, 0.4%, 0.6%, 0.8% on solid culture plates, cultured at 30°C, and observed the growth of plate colonies every 12 hours;

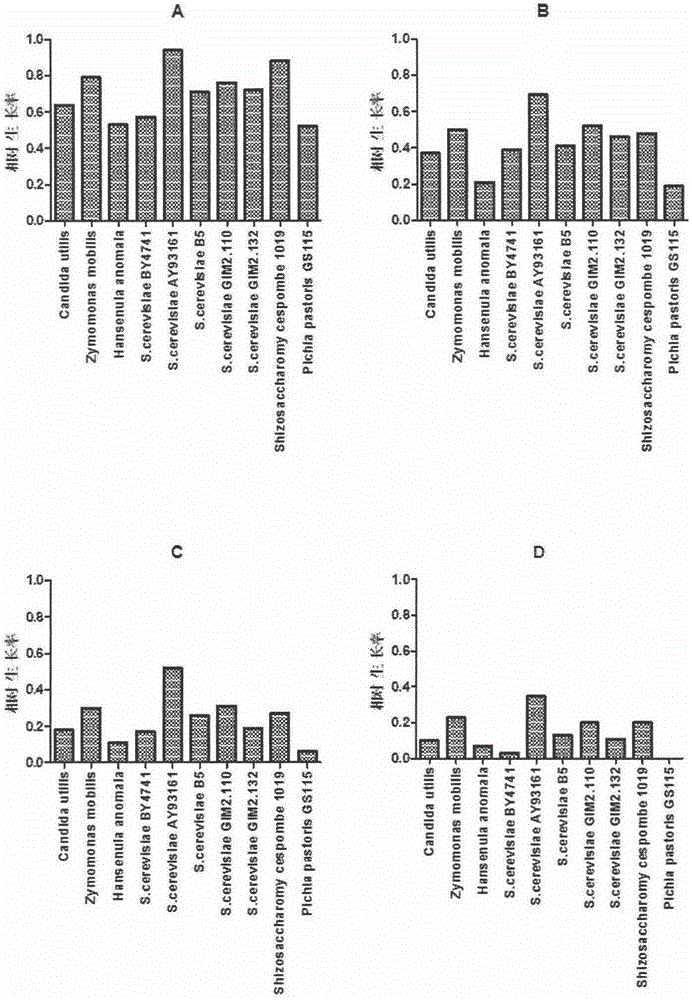

[0024] (2) Tolerance analysis: pick the tolerant single colony on the solid culture plate containing benzaldehyde 0.2%, 0.4%, 0.6%, inoculate to 150ml containing 0.2%, 0.4%, 0.6%, 0.8% benzaldehyde respectively Fermentation 24h' in the seed culture medium

[0025] (3) by OD 600 =0.1 initial cell concentration inoculated into the same high-concentration seed culture mediu...

Embodiment 2

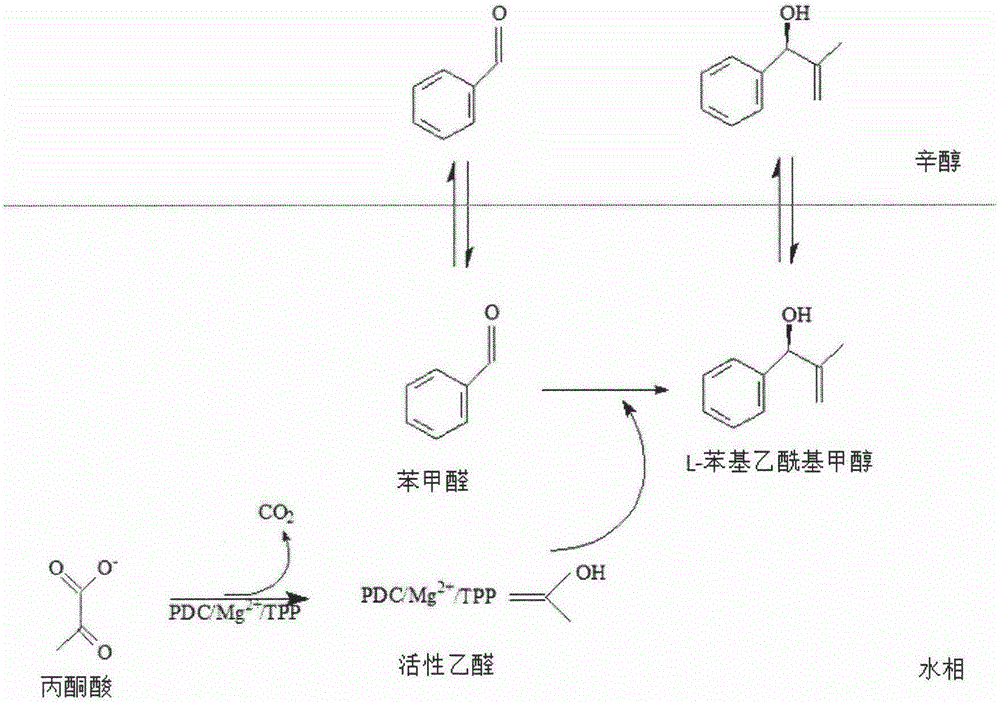

[0027] Example 2 Biosynthesis of L-PAC

[0028] (1) Construction of biocatalyst

[0029] Utilize composite carrier to immobilize benzaldehyde tolerant yeast strain, be biocatalyst; Wherein, described composite carrier is the immobilization buffer containing polyvinyl alcohol and sodium alginate, and described immobilization buffer is containing 20mmol / LMgSO 4 and 0.5MKH of 1mmol / L thiamine pyrophosphate (TPP) 2 PO 4 / K 2 HPO 4 Buffer, the mass percentage concentration of the polyvinyl alcohol is 5-15%; the mass percentage concentration of the sodium alginate is 1.5-2.5%;

[0030] The specific operation is: add polyvinyl alcohol and sodium alginate and 1g of benzaldehyde-tolerant yeast strain to 4ml of 20mmol / LMgSO 4 and 0.5MKH of 1mmol / L thiamine pyrophosphate (TPP) 2 PO 4 / K 2 HPO 4 In the buffer solution, after mixing, use a 20ml syringe to draw the mixture and drop it into 4% CaCl containing 0.2% glutaraldehyde at 4°C 2 Granulate and solidify in saturated boric ac...

Embodiment 3

[0041] This example is basically the same as Example 2, except that in step (3), 1.2% additive β-cyclodextrin is added to the reaction system.

[0042] HPLC detection was performed on the finally obtained reaction liquid, and the concentration of the prepared L-PAC was 34 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com