Preparation method and applications of copper oxychloride isomeride

A technology of isomers and copper chloride is applied in the field of preparation of basic copper chloride, which can solve the problems of strong oxidation, hardening and corrosion processing, and destruction of vitamins, and is suitable for large-scale production, convenient storage and use , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0050] Botallackite, the raw material used in all of the following embodiments, is obtained according to the preparation method vegetation comprising the following steps:

[0051] A1: Prepare respectively ammonium chloride aqueous solution, copper chloride aqueous solution (wherein copper concentration is 200g / L) and NH 3 The mass concentration is 12% aqueous ammonia solution;

[0052] A2: Preheating the ammonium chloride aqueous solution, the copper chloride aqueous solution and the ammonia aqueous solution respectively, so that the temperatures of these three solutions are all 85° C.;

[0053] A3: Add the ammonium chloride aqueous solution into the reactor, the amount added is 50% of the total volume of the material when the reaction ends, then add the copper chloride aqueous solution and ammonia aqueous solution while stirring, and control the pH of the reaction system to be 5.5 , the reaction feeding time is 25min, the copper chloride in the copper chloride aqueous soluti...

Embodiment 1

[0055] Preparation concentration is 20% calcium chloride aqueous solution;

[0056] 1000 kilograms of feed-grade botallackite and 4000 liters of water are added to the reactor, stirred while feeding steam, and 400 liters of prepared calcium chloride aqueous solution is added to the reactor to form a reaction system, mixed, stirred, Heat the reaction system at 75°C, add aqueous ammonia solution to control the pH of the reaction system to be 5, and control the reaction time to 120min to generate a precipitate, which is paratacamite precipitation, that is, a basic copper chloride with isomers;

[0057] The generated paratacamite precipitation is filtered, washed with tap water, dried at 105°C, and sieved through a sieve with a diameter of 45 μm to obtain a particle size greater than 45 μm and a weight of 990 kg (i.e. the conversion rate from raw materials to products) Up to 99%) dark green paratacamite powder, named P1.

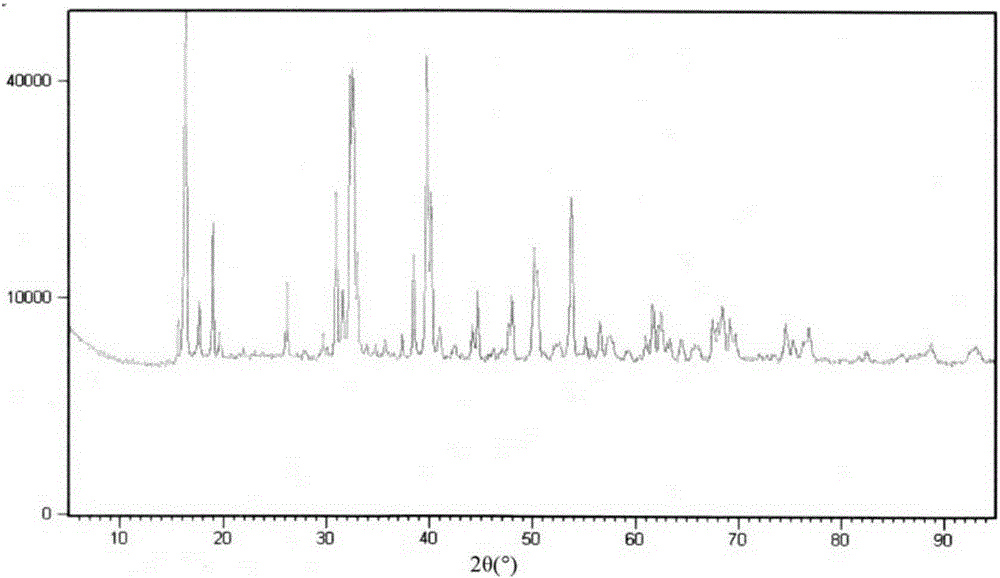

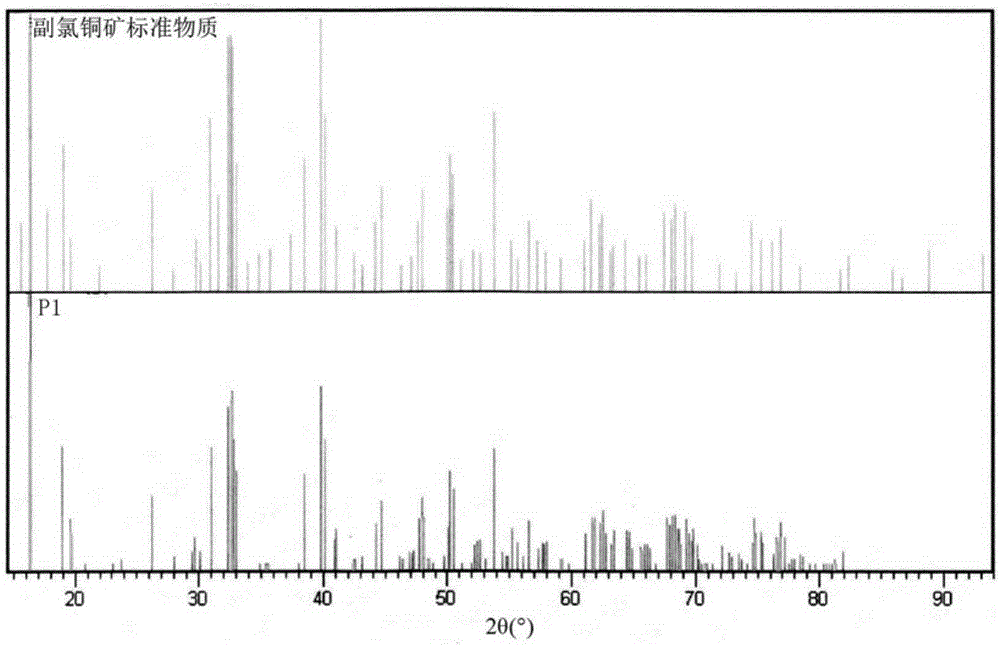

[0058] like figure 1 , figure 2 As shown, the Nationa...

Embodiment 2

[0061] Preparation concentration is 5% calcium chloride aqueous solution;

[0062] Add 1200 kilograms of feed grade Botallackite and 4000 liters of water into the reactor, stir while introducing steam, and add 800 liters of prepared calcium chloride aqueous solution into the reactor to form a reaction system, mix, stir, Heat the reaction system at 50°C, add aqueous ammonia solution to control the pH of the reaction system to be 7, and control the reaction time to 300min to generate a precipitate, which is paratacamite precipitation, that is, a basic copper chloride with isomers;

[0063] The generated paratacamite precipitate was filtered, washed with tap water, dried at 105°C, and sieved through a sieve with a diameter of 45 μm to obtain a dark green paratacamite powder with a particle size greater than 45 μm and a weight of 1190 kg. Name it P2.

[0064] like figure 1 , figure 2 As shown, the National 863 Shenzhen Material Surface Analysis and Testing Center uses RigakuD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com