Ceramic fiber heat insulation plate

A technology of ceramic fiber and heat insulation board, which is applied in the field of inorganic refractory materials, to achieve the effect of increasing the service temperature, good stability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

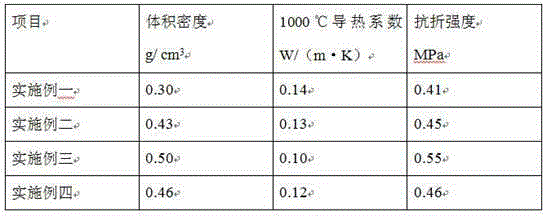

Examples

Embodiment 1

[0019] A ceramic fiber heat insulation board, the ceramic fiber heat insulation board is made of the following raw materials in parts by weight: 3 parts of nano-scale titanium dioxide, 4 parts of nano-scale alumina, 2 parts of vanadium pentoxide, and 5 parts of nano-scale silicon carbide , 35 parts of micron-sized silicon carbide, 1 part of dispersant, 3 parts of zirconium latex, 4 parts of dolomite powder, 30 parts of micron-sized alumina; diameter is 12 μm, the particle diameter of the nanoscale titanium dioxide is 40nm, the particle diameter of the nanoscale silicon carbide is 40nm, and the particle diameter of the micronscale silicon carbide is 8 μm; the dispersant is sodium silicate and calcium carbonate The mixture of sodium silicate and calcium carbonate in a mass ratio of 3:1, the zirconium latex is a mixture of zirconium dioxide, diyttrium trioxide and hydrogen peroxide, the zirconium dioxide and diyttrium trioxide The mass ratio is 95:5, and the mass ratio of zirconi...

Embodiment 2

[0027] A ceramic fiber heat insulation board, the ceramic fiber heat insulation board is made of the following raw materials in parts by weight: 5 parts of nano-scale titanium dioxide, 9 parts of nano-scale alumina, 8 parts of vanadium pentoxide, and 7 parts of nano-scale silicon carbide , 45 parts of micron-sized silicon carbide, 5 parts of dispersant, 4 parts of zirconium latex, 8 parts of dolomite powder, and 40 parts of micron-sized alumina; diameter is 17 μm, the particle diameter of the nanoscale titanium dioxide is 20nm, the particle diameter of the nanoscale silicon carbide is 30nm, and the particle diameter of the micronscale silicon carbide is 4 μm; the dispersant is sodium silicate and calcium carbonate The mixture of sodium silicate and calcium carbonate in a mass ratio of 3:1, the zirconium latex is a mixture of zirconium dioxide, diyttrium trioxide and hydrogen peroxide, the zirconium dioxide and diyttrium trioxide The mass ratio is 95:5, and the mass ratio of zi...

Embodiment 3

[0035]A ceramic fiber heat insulation board, the ceramic fiber heat insulation board is made of the following raw materials in parts by weight: 4 parts of nano-scale titanium dioxide, 6 parts of nano-scale alumina, 4 parts of vanadium pentoxide, and 6 parts of nano-scale silicon carbide , 40 parts of micron-sized silicon carbide, 3 parts of dispersant, 3.5 parts of zirconium latex, 6 parts of dolomite powder, 35 parts of micron-sized alumina; the particle diameter of the nano-sized alumina is 60nm, and the particle size of the micron-sized alumina diameter of 15 μm, the particle size of the nano-sized titanium dioxide is 30 nm, the particle size of the nano-sized silicon carbide is 35 nm, and the particle size of the micron-sized silicon carbide is 7 μm; the dispersant is sodium silicate and calcium carbonate The mixture of sodium silicate and calcium carbonate in a mass ratio of 3:1, the zirconium latex is a mixture of zirconium dioxide, diyttrium trioxide and hydrogen peroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com