Fiber-reinforced type polyether sulphone alloy blended and modified resin and preparation method thereof

A polyarylethersulfone and blending modification technology is applied in the field of fiber-reinforced polyarylethersulfone alloy blending modified resin and its preparation, which can solve the problem of difficulty in increasing molecular weight, large loss of sulfolane recovery rate, weakening of polymerization rate, etc. To solve the problem of mechanical properties, shorten the reaction time, and improve the mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

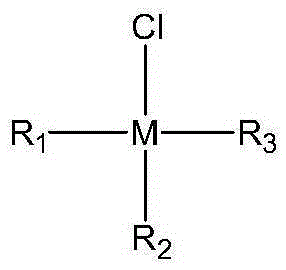

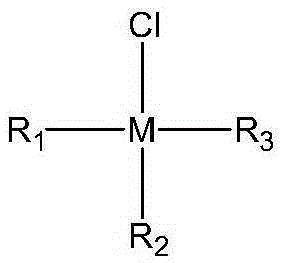

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of chain-extended polyaryl ether sulfone resin

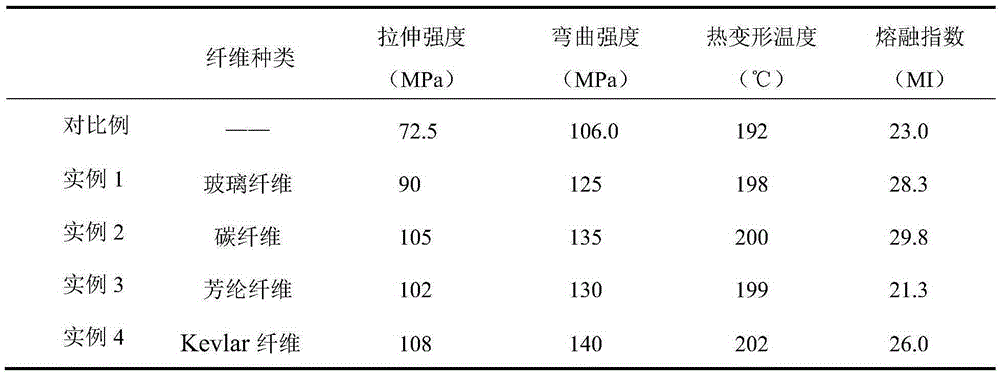

[0038] In a 300L stainless steel reaction kettle equipped with a nitrogen pipe, a condensing water separator and a high-efficiency stirrer, first add 85.00KG sulfolane and start stirring to raise the temperature to 80°C, and then add 36.0KG4,4'-dichlorodiphenylsulfone, 23.0KG 4,4′-biphenyldiphenol, after the monomers are completely dissolved, add 15.0KG sodium carbonate to the system when the temperature rises to 110°C, then add 65.0 liters of tetramethylbenzene, continue to stir and heat up to 200°C to form a salt At the beginning of the reaction, the water generated in the system azeotropes with tetramethylbenzene, and cooling water begins to drip from the condenser tube, and layers are separated in the water separator. The salt-forming reaction is complete, the salt-forming stage takes 1.2 hours, and the solid content of the system in the salt-forming reaction stage is 26%; after the salt-forming is com...

Embodiment 2

[0042] Same as Example 1, except that 68% of the polyarylethersulfone resin synthesized above, 15% of pure resin PSU, and 21% of carbon fiber are used instead of glass fiber, other conditions are the same, and the test results are shown in Table 1.

Embodiment 3

[0044] Same as Example 1, except that 75% of the polyarylethersulfone resin synthesized above, 10% of pure resin PSU, and 11% of aramid fiber are used instead of glass fiber, other conditions are the same, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com