Preparation method of fast high-sensitivity photonic crystal humidity sensor

A humidity sensor and photonic crystal technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of poor mechanical properties of sensor devices, high cost of humidity sensors, poor parallel stability, etc. , increase stability and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

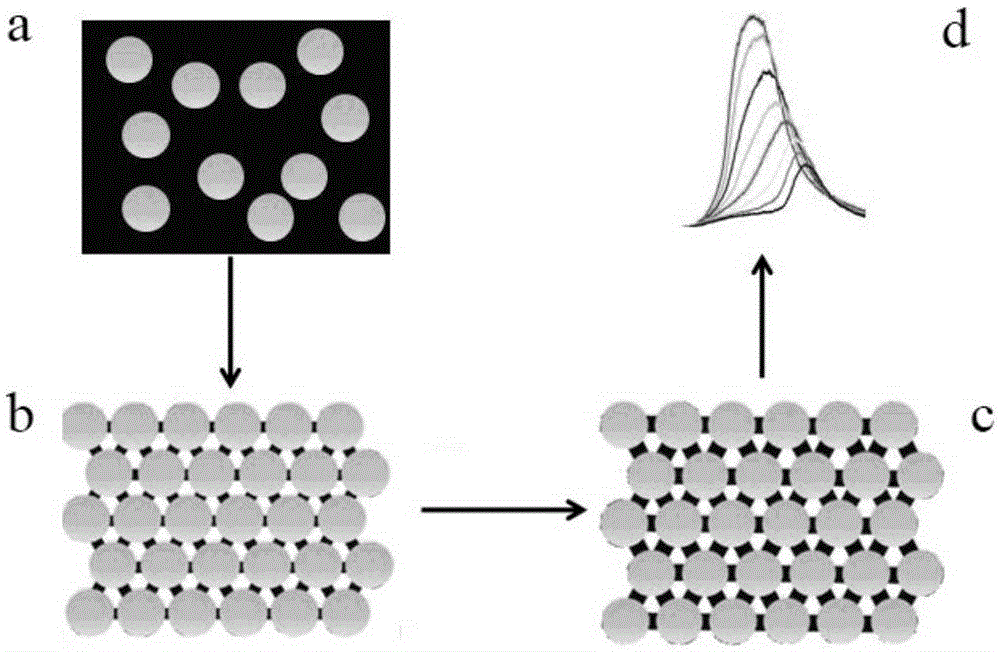

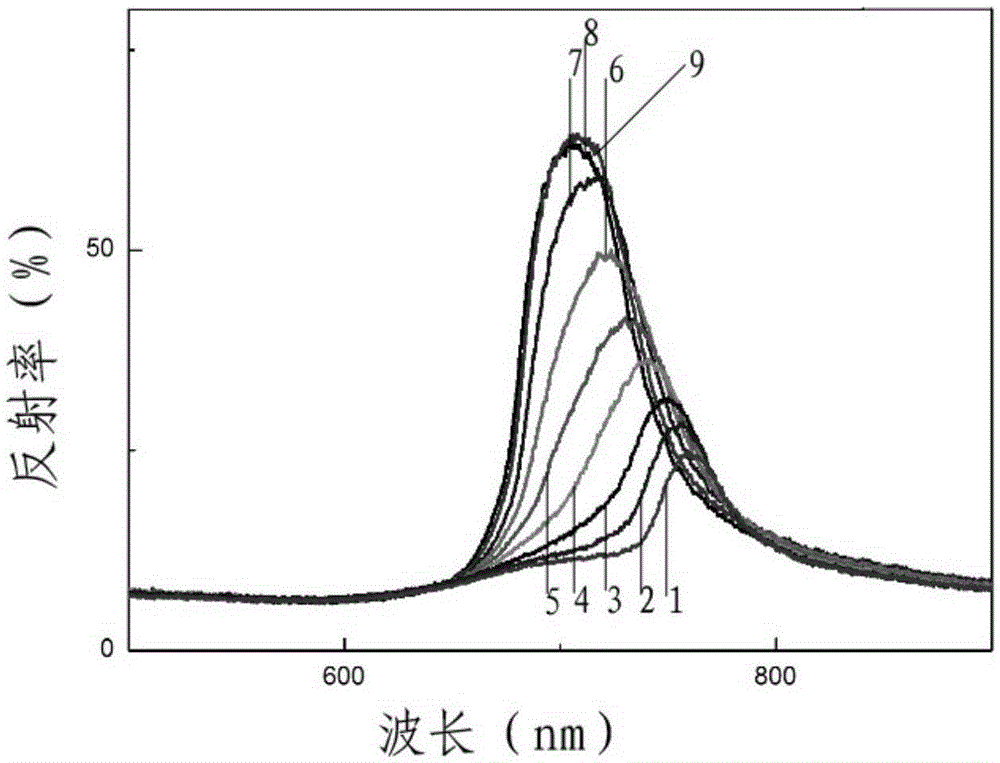

[0019] Specific embodiment one: the preparation method of the fast and highly sensitive humidity sensor of this embodiment is characterized in that: the preparation method of the fast and highly sensitive photonic crystal humidity sensor is carried out according to the following steps:

[0020] 1. Treatment of the base material: place the base material in a mixed solution of hydrogen peroxide with a mass fraction of 25% to 35% and concentrated sulfuric acid with a mass fraction of 96% to 98% in a volume ratio of 1: (2 to 3) Ultrasonic cleaning in medium, followed by ultrasonic cleaning in acetone solution, absolute ethanol solution and ultrapure aqueous solution for 10-20 minutes, and then drying in an oven; remove impurities on the surface of the substrate to ensure the hydrophilicity and cleanliness of the glass substrate;

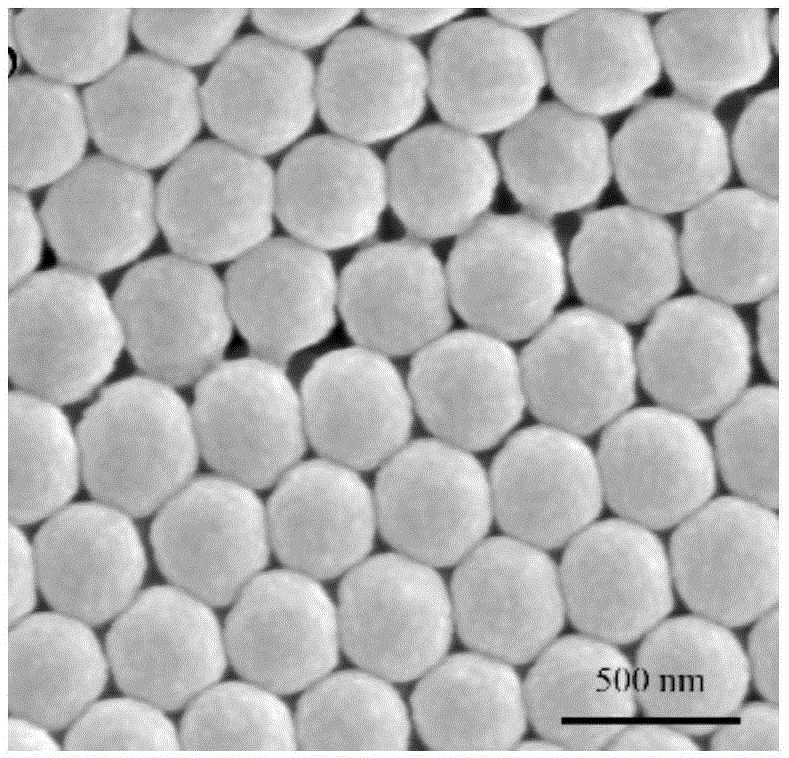

[0021] 2. Prepare the assembly solution: take the microsphere material and disperse it in ethanol with a mass fraction of 98% to 99% to prepare a mixed s...

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the base material described in step 1 is polymethyl methacrylate (PMMA), polypropylene (PP), polycarbonate (PC), polystyrene Methylsiloxane (PDMS), polyvinyl chloride (PVC), polysilicon or amorphous silicon. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the microsphere material described in step 2 is polymethyl polymethyl methacrylate (PMMA), polypropylene (PP), polycarbonate ( PC), polydimethylsiloxane (PDMS), polystyrene (PS) silica (SiO 2 ), titanium dioxide (TiO 2 ) or polyacrylic acid (PAA) and colloidal particles copolymerized between them. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com