Making method of molecularly imprinted electrochemical sensing electrode for detecting propylene chorohydrin

A molecular imprinting and sensing electrode technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of high detection cost, inability to quickly monitor the content of chloropropanol in seasonings in real time, and long detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Synthesis of photocrosslinkable amphiphilic random copolymers

[0016] Weigh a certain amount of DMA, HEA, EHA, St and initiator AIBN into a three-necked flask, add an appropriate amount of ethyl acetate as a solvent, stir evenly at room temperature, and react at 80°C for 20h. AIBN was dissolved in ethyl acetate and added dropwise to the constant temperature reaction system. After the dropwise addition, the temperature of the system was raised to 90° C., and the reaction was continued for 4 hours to obtain the amphiphilic acrylate random copolymer Poly(DMA-co-HEA-co-EHA-co-St).

[0017] Add a certain amount of IPDI and an appropriate amount of solvent ethyl acetate into a three-necked flask equipped with a thermometer, a stirrer and a dropping funnel, add dropwise HEA, stir at room temperature for 2 hours, use DBTDL as a catalyst and DBHT as an initiator, and react at 50°C for 5 hours , to obtain isocyanates with terminal unsaturated bonds.

[0018] Graftin...

Embodiment 2

[0020] Example 2: Preparation of molecularly imprinted micelles

[0021] Dissolve the polymer, template molecule and photoinitiator benzophenone in ethylene glycol butyl ether, and add an appropriate amount of lactic acid to the polymer mixed solution to adjust the pH, and stir to make the template molecule and the polymer fully interact to form a complex things. Then, the precipitant water is slowly dropped into the solution to induce it to form molecularly imprinted polymer micelles, and then it is added into a large amount of water to fix the micelles to obtain an imprinted micellar solution.

Embodiment 3

[0022] Example 3: Preparation of molecularly imprinted electrochemical electrodes

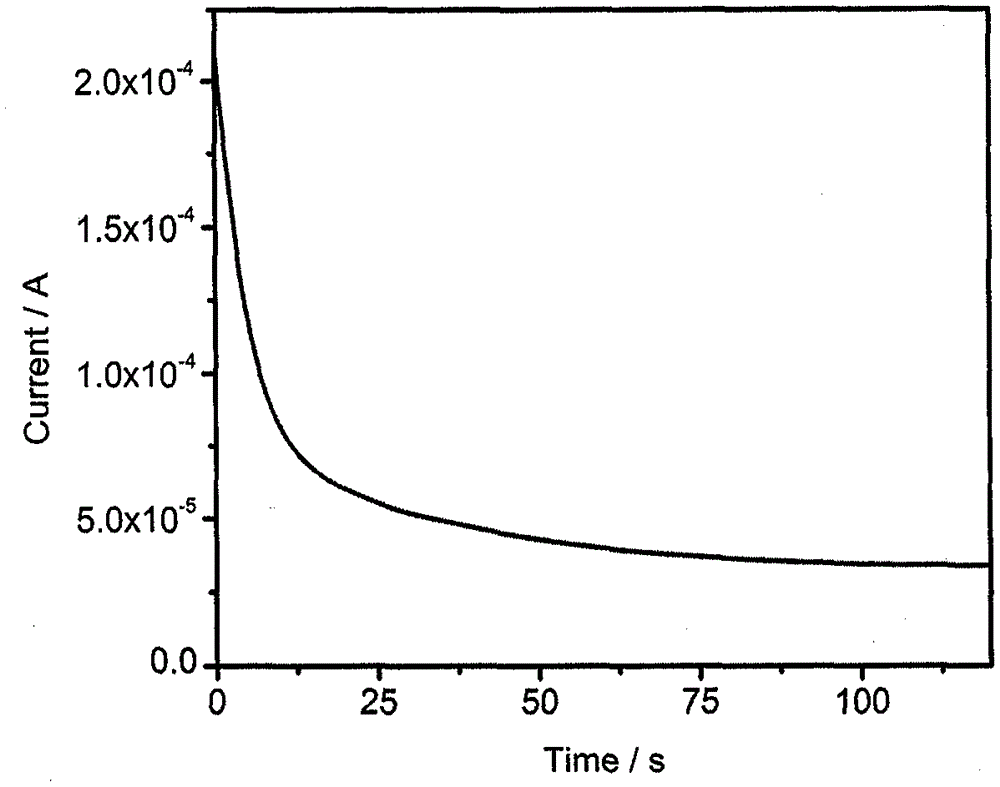

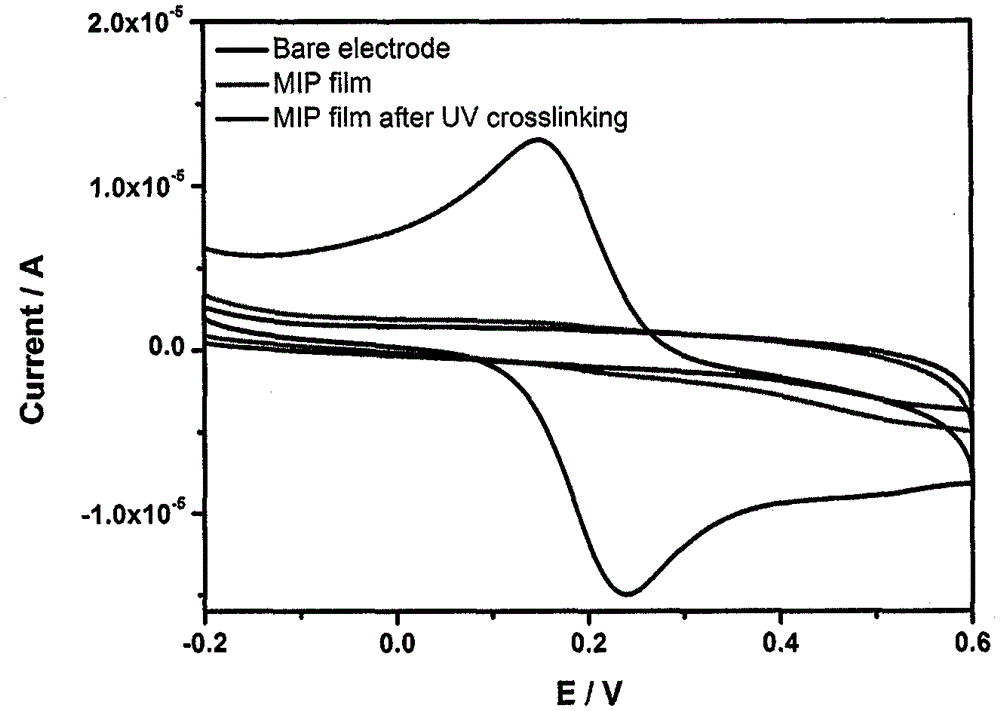

[0023] Polish the bare gold electrode with polishing powder, then ultrasonically clean it with absolute ethanol and water for 5 minutes, and finally rinse it with ultrapure water repeatedly, and dry it for later use. Using the chloropropanol molecularly imprinted micellar solution as the electrodeposition solution, the bare gold electrode was deposited in the deposition solution for 120 s by controlled potential electrolysis (CPE) to prepare the molecularly imprinted polymer micellar film. UV light was applied for 10 min to immobilize the polymer membrane to imprint the acupoints. Finally, the template molecules were eluted with a mixed solution of acetic acid and methanol, and stored in air.

[0024] The fabrication of the non-imprinted electrode is the same as above except that the template molecule chloropropanol is not added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com