Preparation method for molybdenum dioxide-active carbon composite material

A composite material, molybdenum dioxide technology, applied in the field of materials science, can solve the problems of difficult purification, complicated process, and many impurities, and achieve the effects of short reaction time, good repeatability, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

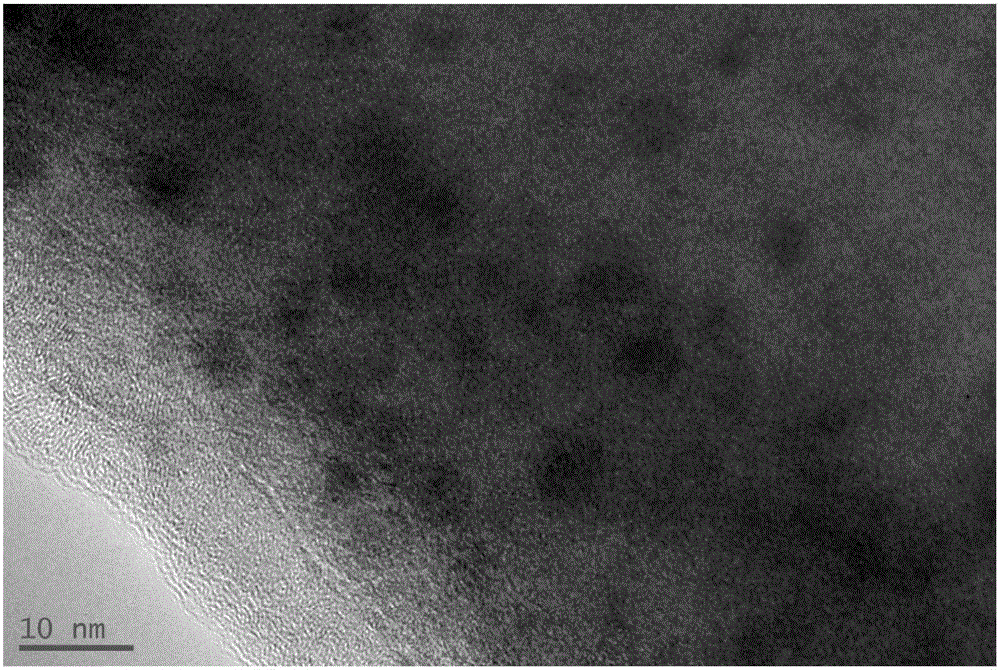

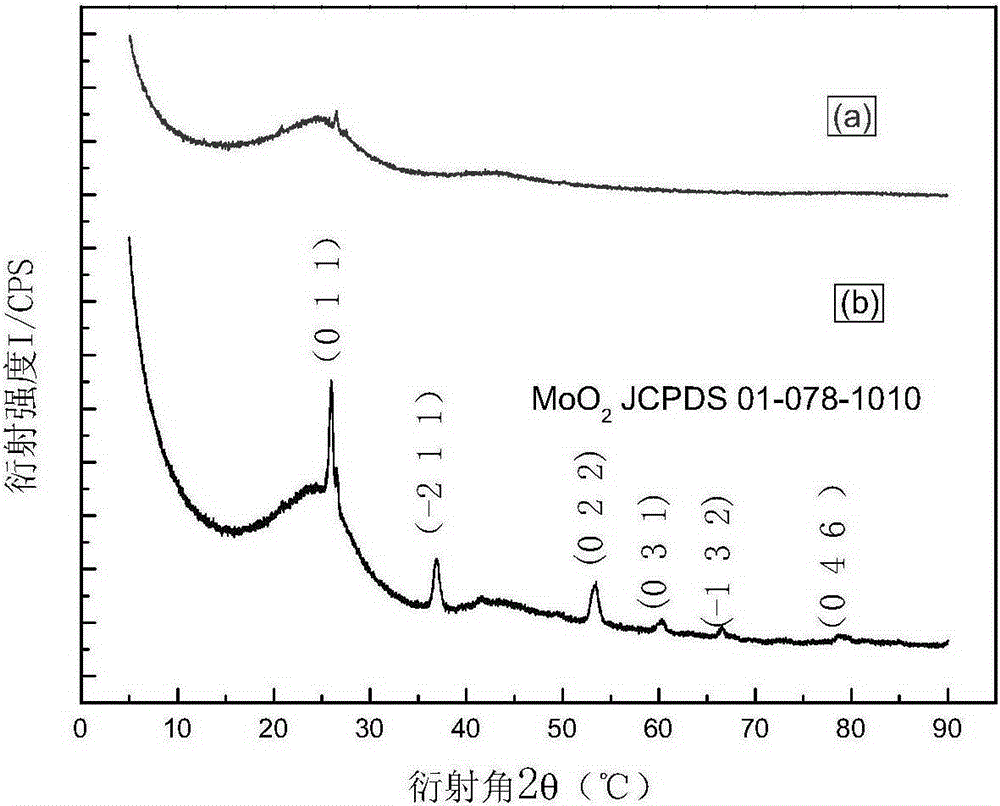

[0030] Use 95mL of 0.025mol / L sodium molybdate solution as the anolyte, and 90mL of 0.025mol / L hydrochloric acid solution as the catholyte. Both cathode and anode use inert electrode titanium mesh, and electrolyze at a constant current of 0.6A for 15min. Repeat this twice to ensure that Na+ can be completely removed or its content is at an extremely low level, then add 0.5g of activated carbon to the molybdic acid solution obtained from the anode tank, soak for 10h under the condition of magnetic stirring, filter , Drying in an oven, put the dried material into a tube furnace in a nitrogen atmosphere at a heating rate of 2.5~10°C / min, and treat it at a high temperature of 400°C for 2 hours to obtain a molybdenum dioxide-activated carbon composite material. The obtained product is tested for EDS and XRD, such as figure 1 .

[0031] By observing figure 1 TEM image, it can be seen that molybdenum dioxide particles are uniformly dispersed in the pores of activated carbon. figu...

Embodiment 2

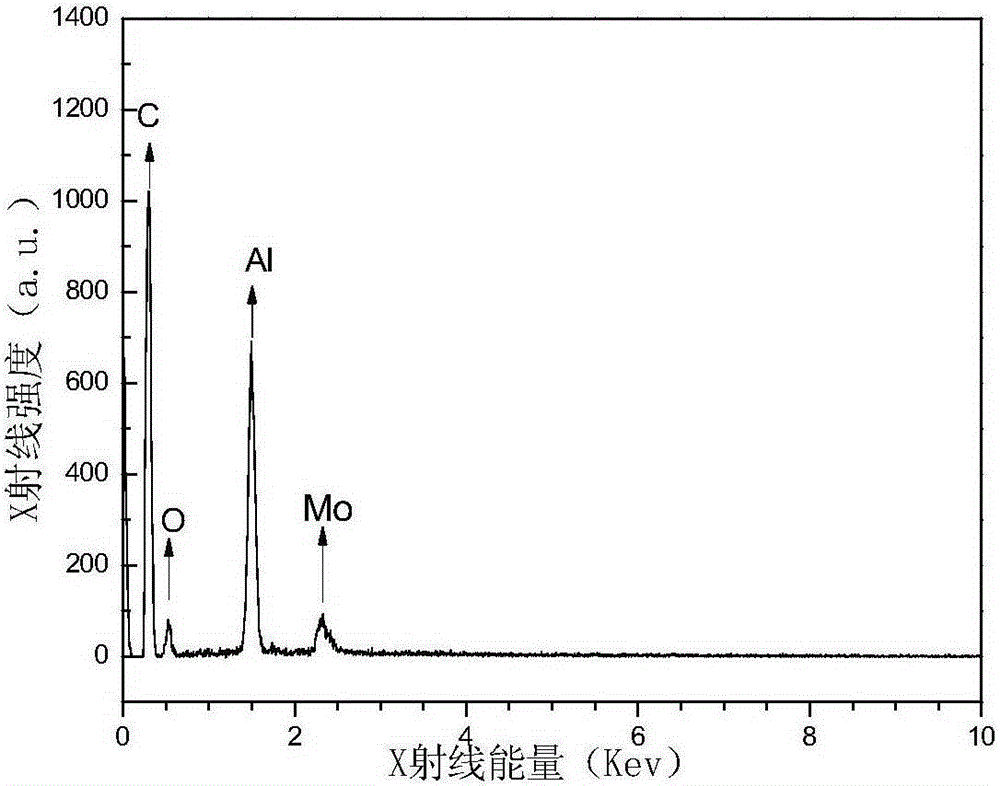

[0033] Use 95mL of 0.01mol / L sodium molybdate solution as the anolyte, and 90mL of 0.01mol / L sodium hydroxide solution as the catholyte. Both cathode and anode use inert electrode titanium mesh, and the constant current 0.6A electrolysis is repeated for 6 minutes. 2 times to ensure Na + It can be completely removed or its content is kept at a very low level, then add 1g of activated carbon into the molybdic acid solution obtained from the anode tank, immerse for 10h under the condition of magnetic stirring, filter, and oven dry, and dry to obtain the substance Put it into a tube furnace in a nitrogen atmosphere at a heating rate of 2.5~10°C / min, and treat it at a high temperature of 400°C for 2 hours to obtain a molybdenum dioxide-activated carbon composite material. The obtained product is tested for EDS and XRD, such as image 3 , 4 .

[0034] By observing image 3 From the EDS diagram, it can be obtained that there are only three elements of Al, Mo, and O in the product...

Embodiment 3

[0036] Use 95mL of 0.05mol / L sodium molybdate solution as the anolyte, and 90mL of 0.05mol / L sodium chloride solution as the catholyte. Both cathode and anode use inert electrode titanium mesh, and electrolyze at a constant current of 0.6A for 30min. This is repeated twice to ensure that Na + It can be completely removed or its content is kept at a very low level, then add 1g of activated carbon into the molybdic acid solution obtained from the anode tank, impregnate for 6 hours under the condition of magnetic stirring, filter, and oven dry, and dry the obtained substance Put it into a tube furnace in a nitrogen atmosphere at a heating rate of 2.5~10°C / min, and treat it at a high temperature of 400°C for 2 hours to obtain a molybdenum dioxide-activated carbon composite material.

[0037] By observing Figure 5From the EDS diagram, it can be obtained that there are only three elements of Al, Mo, and O in the product, and Al is the element introduced during the sample preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com