A kind of preparation method of catalytic carbon paper

A technology of catalytic carbon and carbon paper, which is applied in the direction of solid electrolyte fuel cells, structural parts, electrical components, etc., can solve the problem of merging the catalytic layer and diffusion layer of fuel cells, and achieve the improvement of free carrier density and oxygen reduction catalysis Good activity and widening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

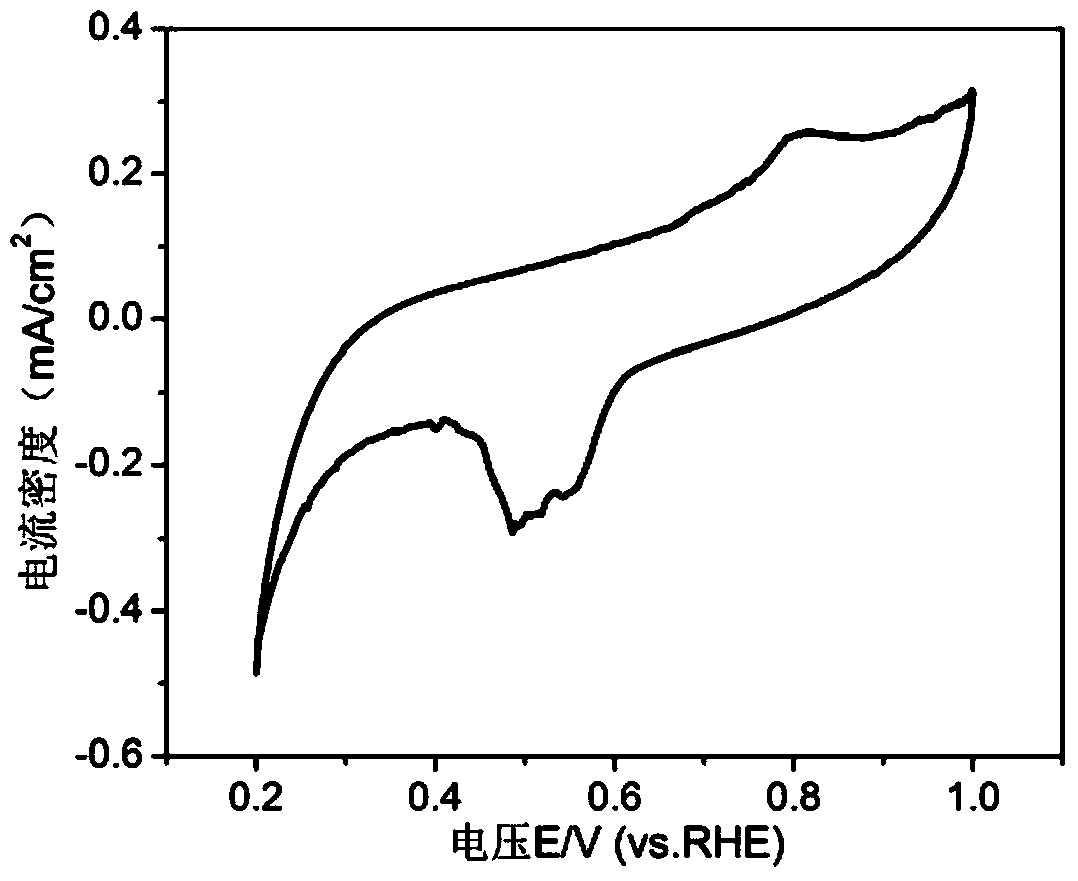

Embodiment 1

[0020] Using natural phosphorus flake graphite as raw material, concentrated sulfuric acid, sodium nitrate, and potassium permanganate as oxidant, prepare graphite oxide solution by Hummers method, put the prepared graphene oxide solution into alcohol for ultrasonic treatment for 2 hours, and then put it into electrolysis In the tank, fiber carbon paper treated at a high temperature of 2800°C was used as the working electrode. After a DC voltage of -1.8V was applied for 2 hours, the graphene oxide was reduced to graphene, and the graphene was coated on the carbon paper; the prepared carbon paper Place in vacuum drying at 50°C for 24 hours; the carbon paper obtained above is doped with nitrogen and sulfur under the gas deposition method with nitrogen source and sulfur source gas, at 800°C, catalyzed after 2 hours Carbon paper, in which the volume ratio of ammonia gas to hydrogen sulfide gas is 1:2. The obtained catalytic carbon paper has good oxygen reduction catalytic activity...

Embodiment 2

[0022] Using natural phosphorus flake graphite as raw material, concentrated sulfuric acid, sodium nitrate, and potassium permanganate as oxidant, prepare graphite oxide solution by Hummers method, put the prepared graphene oxide solution into alcohol for ultrasonic treatment for 2 hours, and then put it into electrolysis In the tank, fiber carbon paper treated at a high temperature of 2500°C was used as the working electrode. After a DC voltage of -1.75V was applied for 3 hours, the graphene oxide was reduced to graphene, and the graphene was coated on the carbon paper; the prepared carbon paper Place in vacuum drying at 50°C for 24 hours; the carbon paper obtained above is doped with nitrogen and sulfur under the gas deposition method with nitrogen source and sulfur source gas, and catalyzed at 700°C after 2 hours. Carbon paper, in which the volume ratio of ammonia gas to hydrogen sulfide gas is 1:1. The obtained catalytic carbon paper has good catalytic activity for oxygen ...

Embodiment 3

[0024] Using natural phosphorus flake graphite as raw material, concentrated sulfuric acid, sodium nitrate, and potassium permanganate as oxidants, the Hummers method is used to prepare graphite oxide solution, and the prepared graphene oxide solution is put into alcohol for ultrasonic treatment for 2.5 hours, and then placed in electrolysis In the tank, fiber carbon paper treated at a high temperature of 2480°C was used as the working electrode. After a DC voltage of -1.7V was applied for 2.5 hours, the graphene oxide was reduced to graphene, and the graphene was coated on the carbon paper; the prepared carbon paper Place in vacuum drying at 60°C for 26 hours; use the carbon paper obtained above to dope the carbon paper with nitrogen and sulfur under the gas deposition method with nitrogen source and sulfur source gas, and obtain catalytic Carbon paper, in which the volume ratio of ammonia gas to hydrogen sulfide gas is 1:1. The obtained catalytic carbon paper has good cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com