A kind of preparation method of step-release drug carrier based on two-phase system

A two-phase system, step-by-step release technology, used in pharmaceutical formulations, medical preparations with non-active ingredients, liquid delivery, etc., can solve the problems of normal cytotoxic side effects, drug accumulation, etc. The effect of maintaining blood concentration and improving curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

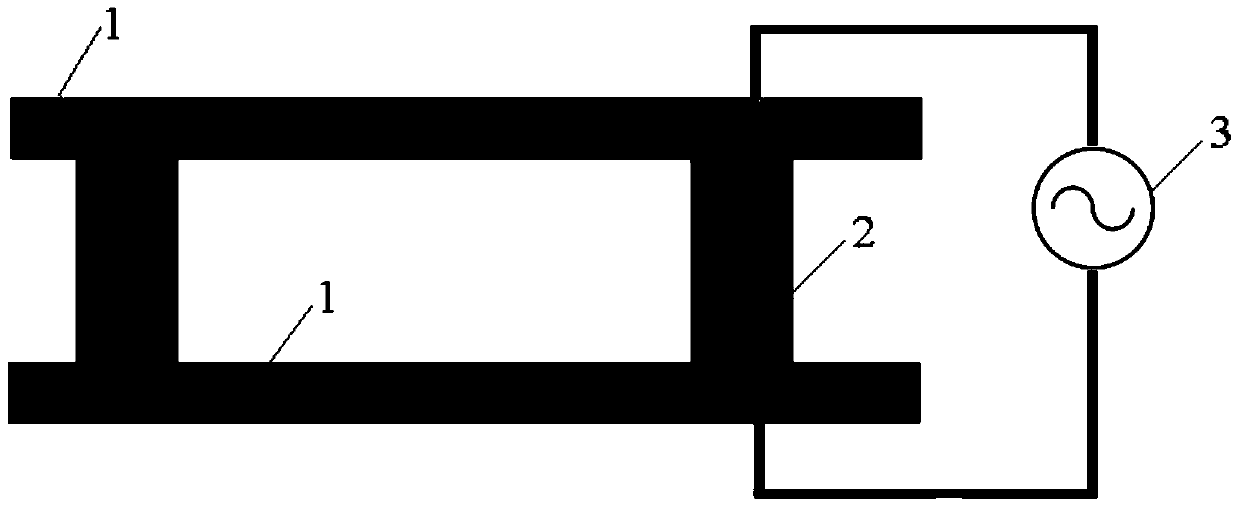

[0024] Specific embodiment 1: This embodiment is a preparation method of a step-by-step release drug carrier based on a two-phase system, which is completed in the following steps:

[0025] 1. ITO surface cleaning: First, use absolute ethanol to ultrasonically clean two pieces of ITO glass electrodes for 15-20 minutes to obtain two pieces of ITO glass electrodes after cleaning with absolute ethanol; then use distilled water to clean the two pieces of ITO glass electrodes with absolute ethanol Electrodes were ultrasonically cleaned for 15-20 minutes, and finally dried with nitrogen to obtain two cleaned ITO glass electrodes;

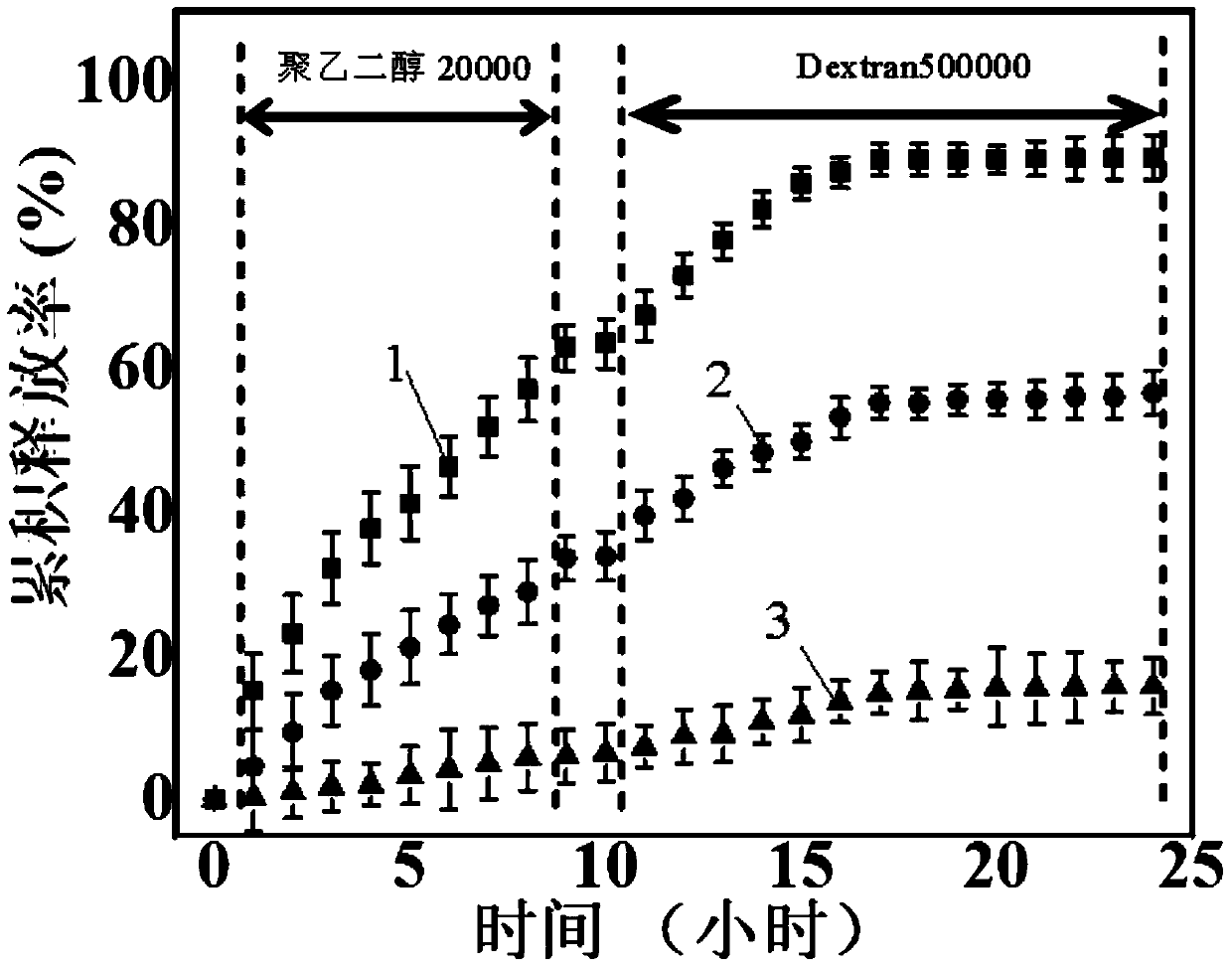

[0026] 2. Dissolve polyethylene glycol 20000 and Dextran500000 in distilled water to obtain a two-phase aqueous solution;

[0027] The volume ratio of the mass of polyethylene glycol 20000 described in step 2 to distilled water is 0.09g: (2.5mL~3mL);

[0028] The volume ratio of the mass of Dextran500000 described in step 2 to distilled water is 0.1g: (2...

specific Embodiment approach 2

[0039] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass of dipalmitoylphosphatidylcholine described in step three and the volume ratio of chloroform are 5mg:1mL. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the polyethylene glycol 20000 described in step 2 to distilled water is 0.09g:2.8mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com