Method for doping synthesized sulfur with graphene

A technology of sulfur-doped graphene and graphene gel, which is applied in the field of synthesizing sulfur-doped graphene, can solve the problems of high cost, low yield, complicated preparation process of sulfur-doped graphene, etc., and achieves large processing capacity and high cost. Inexpensive and easy to scale up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

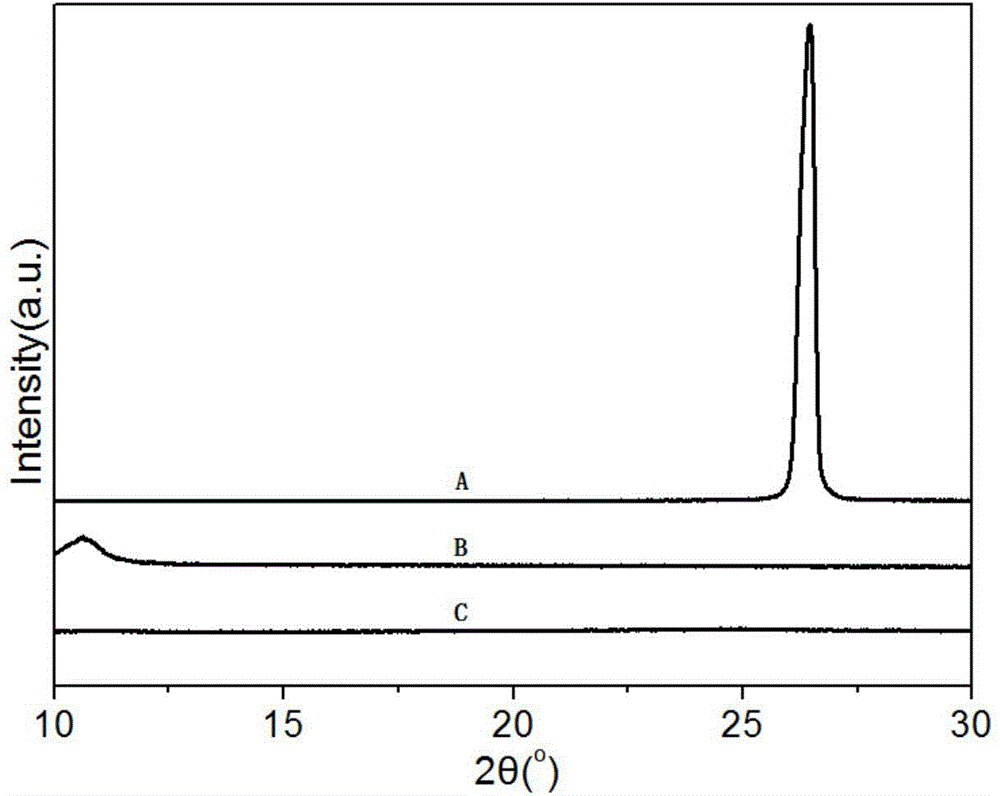

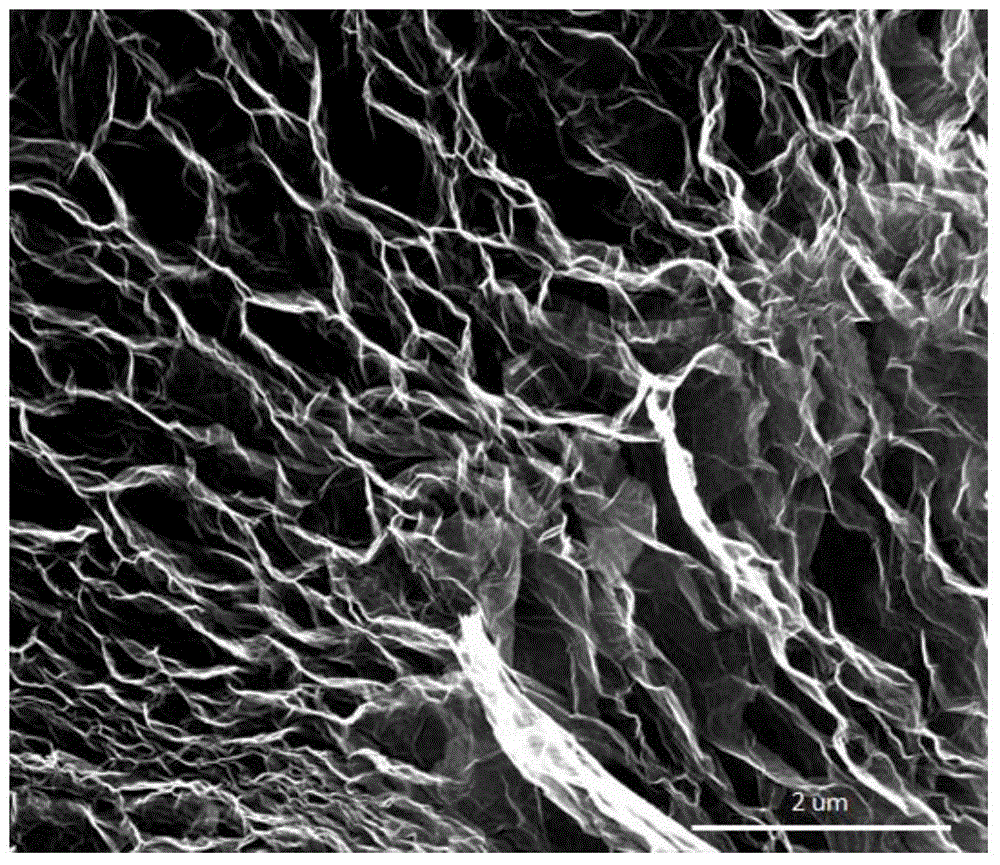

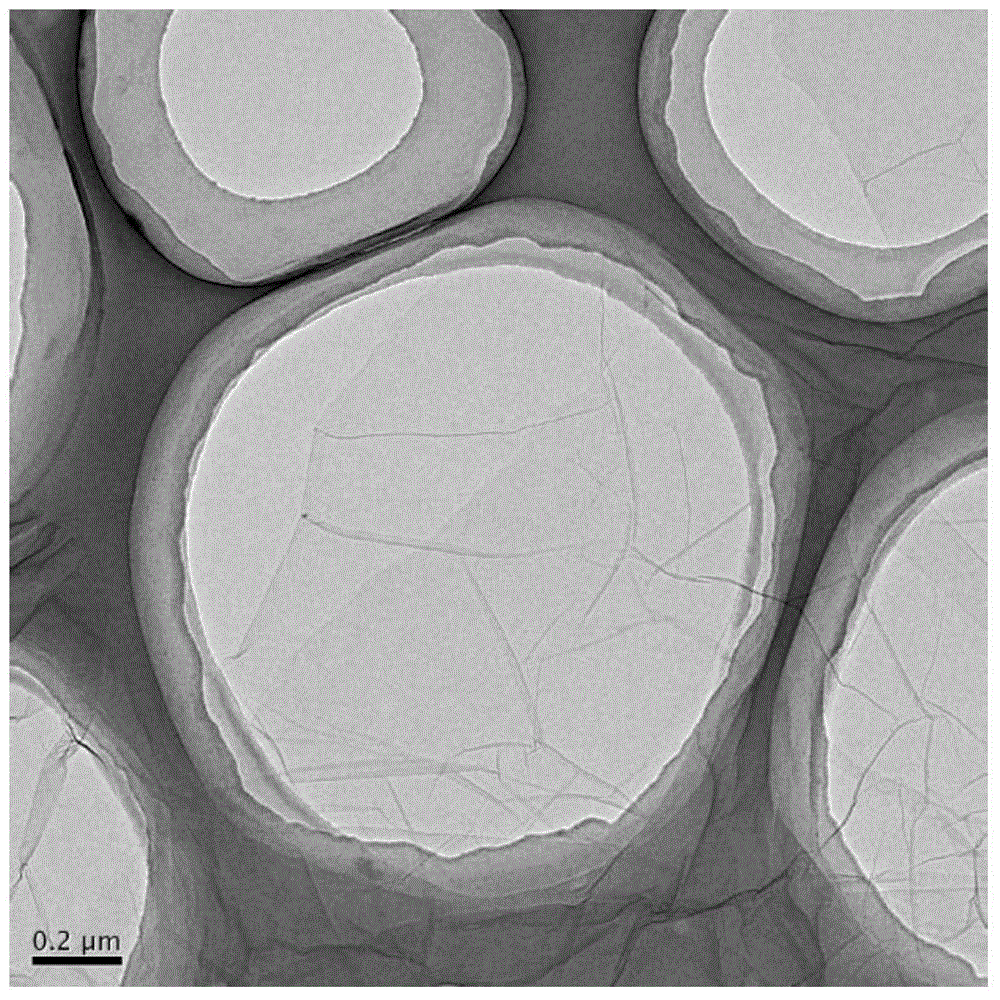

[0028] 300 mg of graphite oxide was ultrasonically stripped in 100 ml of deionized water for 1.5 hours to prepare a 3 mg / ml graphene oxide solution, which was freeze-dried at -40°C for 24 hours to obtain a porous graphene oxide gel, and the volume percentage of hydrogen sulfide was introduced A mixed gas of 20% hydrogen sulfide and nitrogen was reacted at 900° C. for 30 minutes and cooled to room temperature to obtain sulfur-doped graphene, wherein the atomic percentage of sulfur was 1.65%.

[0029] The obtained sulfur-doped graphene X-ray diffraction spectrum (XRD) figure, scanning electron microscope (SEM) figure, transmission electron microscope (TEM) figure, and X-ray photoelectron spectrum (XPS) figure see accompanying drawing, show that sulfur atom Already replaced carbon atoms into the graphene lattice.

Embodiment 2

[0031] 50 mg of graphite oxide was ultrasonically stripped in 100 ml of deionized water for 1 hour to prepare a 0.5 mg / ml graphene oxide solution, which was freeze-dried at -40°C for 48 hours to obtain a porous graphene oxide gel, and the volume percentage of hydrogen sulfide was introduced A mixed gas of 5% hydrogen sulfide and nitrogen was reacted at 550° C. for 2 hours and cooled to room temperature to obtain sulfur-doped graphene, wherein the atomic percentage of sulfur was 2.37%.

[0032] The obtained sulfur-doped graphene X-ray diffraction spectrum (XRD) figure, scanning electron microscope (SEM) figure, transmission electron microscope (TEM) figure, and X-ray photoelectron spectrum (XPS) figure are similar to [embodiment 1] .

Embodiment 3

[0034] 500 mg of graphite oxide was ultrasonically stripped in 100 ml of deionized water for 2 hours to prepare a 5 mg / ml graphene oxide solution, which was freeze-dried at -20°C for 12 hours to obtain a porous graphene oxide gel, and the volume percentage of hydrogen sulfide was introduced A mixed gas of 30% hydrogen sulfide and nitrogen was reacted at 900° C. for 1 hour and cooled to room temperature to obtain sulfur-doped graphene, wherein the atomic percentage of sulfur was 1.53%.

[0035] The obtained sulfur-doped graphene X-ray diffraction spectrum (XRD) figure, scanning electron microscope (SEM) figure, transmission electron microscope (TEM) figure, and X-ray photoelectron spectrum (XPS) figure are similar to [embodiment 1] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com