Rare-earth metal complex, catalyst composition and application

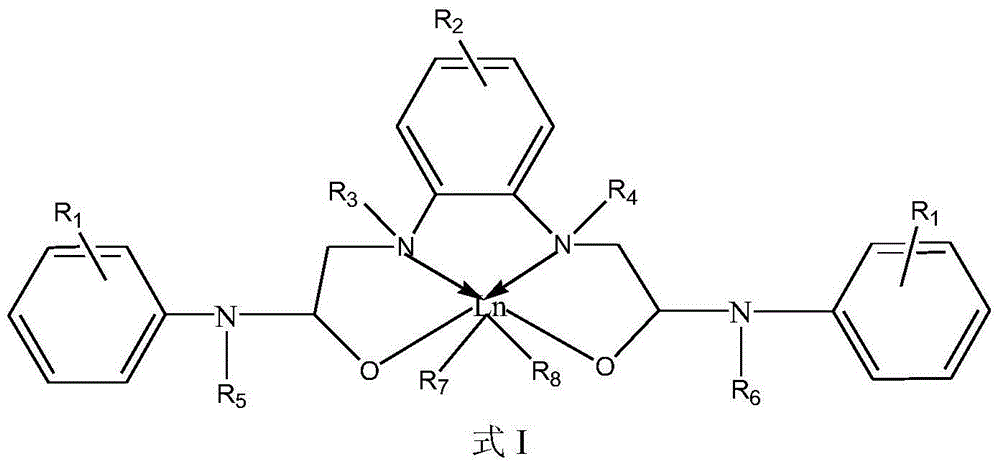

A technology of rare earth metal complexes, which is applied in the field of rare earth metal complexes and catalyst compositions composed of said complexes, and can solve the problems of low polymer molecular weight, conversion rate of only about 50%, and reduced conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

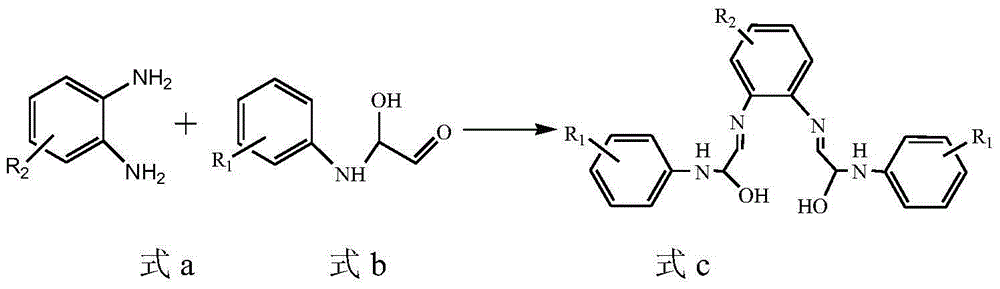

[0049] Preparation of Ligand Compounds:

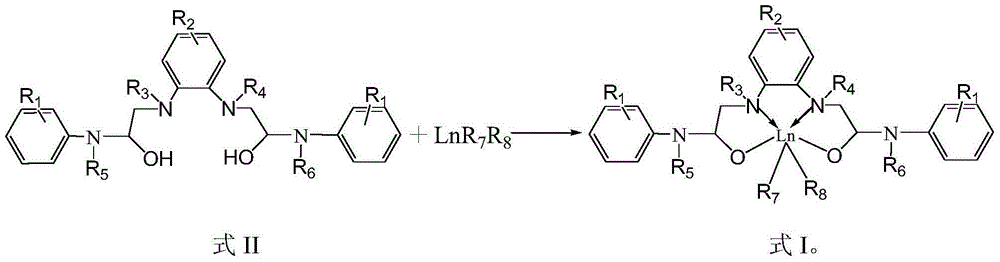

[0050] Preparation of Rare Earth Metal Complex M

[0051] 1) Ligand synthesis

[0052] Add o-phenylenediamine (1.08g, 10mmol) and 2-hydroxy-2-phenylaminoacetaldehyde (3g, 20mmol) into a 100ml round bottom flask, add 20ml of ethanol, and stir at room temperature for 1 hour. Ethyl acetate was added to the reaction solution, and a large amount of white solid was precipitated. The solid was filtered with suction, washed with cold ethyl acetate, and vacuum-dried to obtain bis-imine (2.69 g, 7.8 mmol, yield 78%) as a white solid. Dissolve bisimine (3.46g, 10mmol) and sodium cyanoborohydride (1.26g, 20mmol) in DMF, stir and react at room temperature for 2 hours, add ethyl acetate, a large amount of white solid precipitates, suction filter, and use cold The solid was rinsed with ethyl acetate and dried under vacuum to obtain a white solid of bis-secondary amine (3.3 g, yield 95%).

[0053] The proton nuclear magnetic spectrum data of produc...

Embodiment 1

[0085] At room temperature, add 10 μmol of rare earth metal complex A (Ln is scandium, R 1 , R 2 for hydrogen, R 3 , R 4 , R 5 and R 6 is methyl, R 7 is trimethylsilyl methylene, R 8 nitrate), 20 μmol of benzyl alcohol and 5mL of toluene solvent, react at 20°C for 5 minutes, add 40mmol of lactide monomer, stir and react at 25°C for 15 minutes, add ethanol solution of hydrochloric acid with a volume concentration of 10% to terminate the reaction, The reaction solution was poured into ethanol for sedimentation, filtered to obtain a white solid, and dried in a vacuum oven at 40°C for 48 hours to obtain a polylactide solid with a conversion rate of 98% according to NMR. The molecular weight Mn of polylactide analyzed by GPC was 0.81 million, and the molecular weight distribution Mw / Mn was 1.25.

Embodiment 2

[0087] At room temperature, add 10 μmol of rare earth metal complex G (Ln is yttrium, R 1 , R 2 is methyl, R 3 , R 4 , R 5 and R 6 is ethyl, R 7 is hexamethyldisilazide, R 8nitrate), 20 μmol of benzyl alcohol and 50 mL of toluene solvent, react at 20 ° C for 5 minutes, add 30 mmol of lactide monomer, stir and react at 25 ° C for 3 h, add ethanol solution of hydrochloric acid with a volume concentration of 10% to terminate the reaction , Pour the reaction solution into ethanol to settle, filter to obtain a white solid, dry the white solid in a vacuum oven at 40°C for 48 hours to obtain a polylactide solid, and the conversion rate of NMR test is 98%. The molecular weight Mn of the polylactide analyzed by GPC was 120,000, and the Mw / Mn was 1.03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com