Polygonatum odoratum polysaccharide sulfation method

A polysaccharide from Polygonatum polysaccharides and sulfated technology, which is applied in the field of sulfated esterification, can solve the problems of unfavorable antiviral activity, toxic side effects, adverse reactions, etc., and achieve the effects of high sulfuric acid substitution degree of the product, simple operation, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

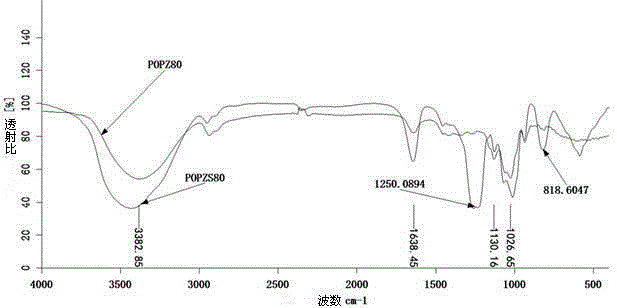

Image

Examples

Embodiment 1

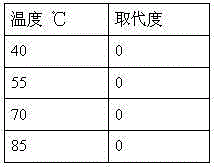

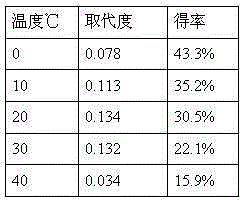

[0019] Take 200mg of dried Polygonatum polysaccharide and add it to 30ml of formamide (water has been removed), stir to dissolve, add 800mg of sulfur trioxide pyridine complex, react at 40°C for 5h, and constantly fill with nitrogen during the reaction. After the reaction, the reaction solution was moved to ice water, and 2 mol / L sodium hydroxide was added to adjust the pH of the solution to between 7 and 8. Concentrate the reaction solution to half its original volume, add 4 times the volume of ice-free ethanol, seal it and put it in a 4°C refrigerator for precipitation for 12 hours, collect the precipitate by centrifugation, wash the precipitate with methanol until the precipitate has no pyridine smell. Add a small amount of deionized water to dissolve in the dialysis bag, first dialyze with tap water for 1 to 2 days, then dialyze with deionized water for 2 days, change the water 2 to 3 times a day. The dialysate was concentrated and then freeze-dried to obtain sulfated Poly...

Embodiment 2

[0021] Take 200mg of dried Polygonatum polysaccharide and add it to 30ml of formamide (water has been removed), stir to dissolve, add 800mg of sulfur trioxide pyridine complex, react at 60°C for 4h, and constantly fill with nitrogen during the reaction. After the reaction, the reaction solution was moved to ice water, and 2 mol / L sodium hydroxide was added to adjust the pH of the solution to between 7 and 8. Concentrate the reaction solution to half of the original volume, add 4 times the volume of ice-free ethanol, seal it and put it in a refrigerator at 4°C for precipitation for 12 hours, collect the precipitate by centrifugation, wash the precipitate with methanol until the precipitate has no pyridine smell. Add a small amount of deionized water to dissolve in the dialysis bag, first dialyze with tap water for 1 to 2 days, then dialyze with deionized water for 2 days, change the water 2 to 3 times a day. The dialysate was concentrated and then freeze-dried to obtain sulfate...

Embodiment 3

[0023] Take 200mg of dried Polygonatum polysaccharide and add it to 30ml of formamide (water has been removed), stir to dissolve, add 800mg of sulfur trioxide pyridine complex, react at 80°C for 6h, and constantly fill with nitrogen during the reaction. After the reaction, the reaction solution was moved to ice water, and 2 mol / L sodium hydroxide was added to adjust the pH of the solution to between 7 and 8. Concentrate the reaction solution to half of the original volume, add 4 times the volume of ice-free ethanol, seal it and put it in a refrigerator at 4°C for precipitation for 12 hours, collect the precipitate by centrifugation, wash the precipitate with methanol until the precipitate has no pyridine smell. Add a small amount of deionized water to dissolve in the dialysis bag, first dialyze with tap water for 1 to 2 days, then dialyze with deionized water for 2 days, change the water 2 to 3 times a day. The dialysate was concentrated and then freeze-dried to obtain sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com