Method for preparing reusable oil-absorbing sponge

The technology of oil-absorbing sponge and melamine sponge is applied in the field of preparation of hydrophobic and lipophilic melamine sponge, which can solve the problems of complicated operation and high cost, and achieve the effects of simple operation, good elasticity and continuous oil absorption improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Containing 40nmSiO 2 Add melamine sponge to the ethanol solution of the particles, SiO 2 The mass ratio of the particle mass to the melamine sponge is 0.8. After stirring for 1 hour, octyltrimethoxysilane with a solution volume fraction of 2% is added dropwise, stirred and reacted for 15 hours, and the solution in the sponge is taken out and squeezed dry, and placed in a vacuum oven to dry to constant weight.

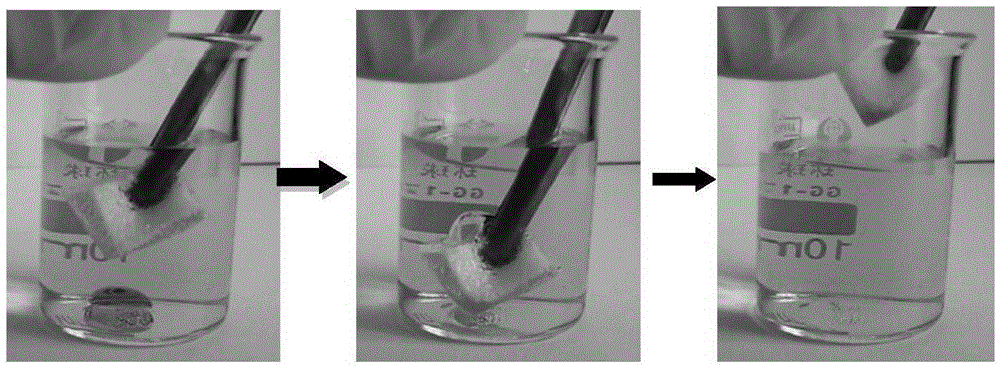

[0031] from figure 1 It can be seen that after the modified melamine sponge is immersed in water, the surface has a phenomenon similar to a "silver mirror". The sponge is wrapped in water droplets but does not absorb water, but it can absorb chloroform that is dyed red by Sudan Red III underwater.

Embodiment 2

[0033] Containing 100nmSiO 2 Add melamine sponge to the ethanol solution of the particles, SiO 2 The mass ratio of the particle mass to the melamine sponge is 5. After stirring for 5 hours, drip vinyltrimethoxysilane with a volume fraction of 20% of the solution, stir and react for 24 hours, take out and squeeze the solution in the sponge, and place it in a vacuum oven to dry to constant weight.

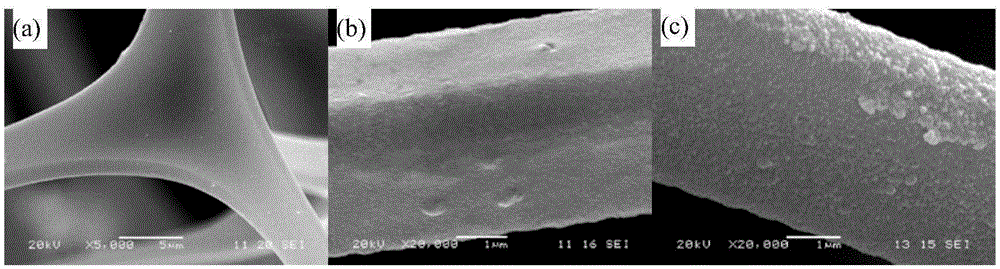

[0034] figure 2 (a) is the scanning electron microscope image of unmodified melamine sponge. It can be seen from the figure that the sponge has a porous three-dimensional network structure. This structure makes the sponge have certain elasticity, and the network holes can also be filled with other substances. , the surface of the sponge skeleton is smooth; (b) is a scanning electron microscope image of a modified melamine sponge, as can be seen from the figure, the sponge still has a porous three-dimensional network structure, and the surface of the skeleton is coated with a small...

Embodiment 3

[0036] Containing 50nmSiO 2 Add melamine sponge to the ethanol solution of the particles, SiO 2 The mass ratio of the particles to the melamine sponge is 4. After stirring for 6 hours, add methyltriethoxysilane with a solution volume fraction of 0.4% dropwise, stir and react for 4 hours, take out and squeeze the solution in the sponge, and dry in a vacuum oven to constant weight.

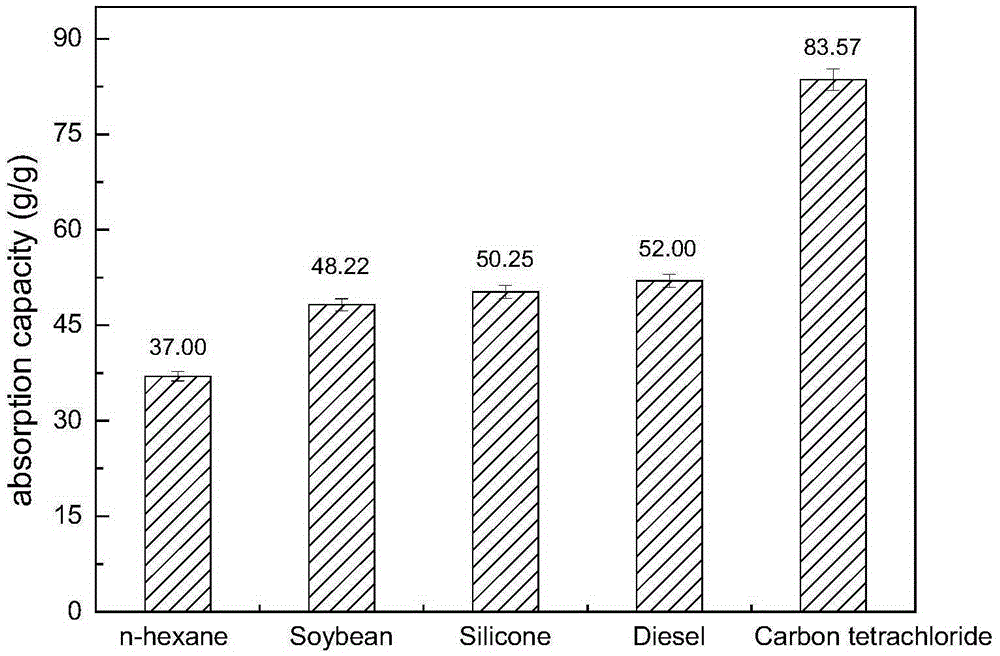

[0037] from image 3 It can be seen that the modified melamine sponge has a high absorption rate for n-hexane, soybean oil, silicone oil, diesel oil, and carbon tetrachloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com