(LMO-NCM-AC)/(LTO-AC) hybrid battery capacitor and preparation method thereof

A technology of LTO-AC and hybrid batteries, which is applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitors, and hybrid capacitor electrodes. Single material performance, good cohesiveness, and the effect of improving the dispersion of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

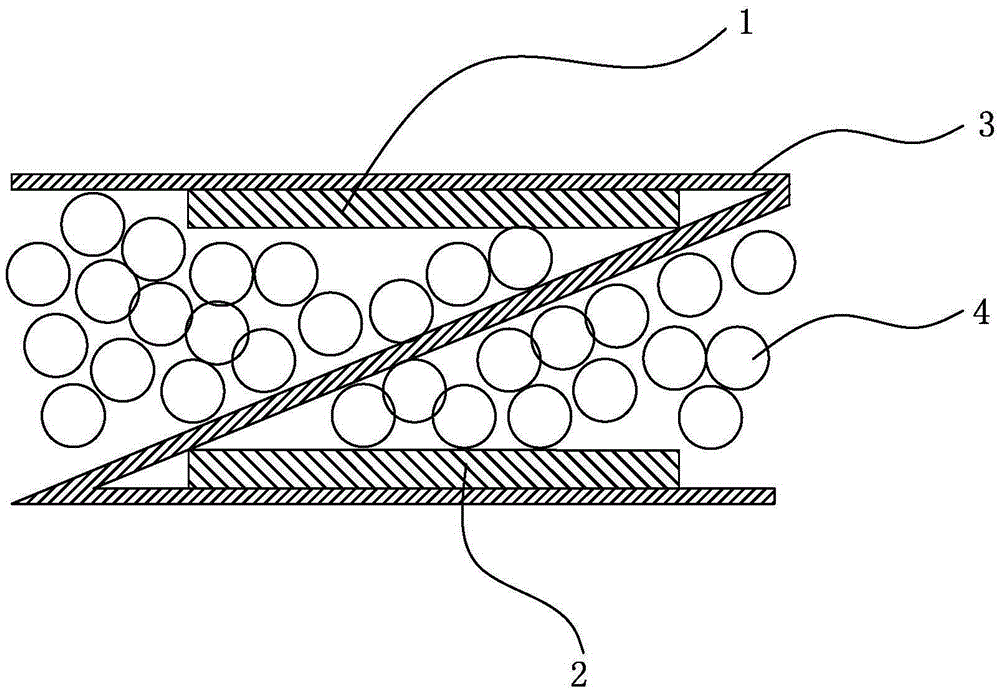

Image

Examples

Embodiment 1

[0043] Dissolve 83% of LMO-NCM (the mass ratio of LMO and NCM is 5:5), 4% of activated carbon, 4% of conductive carbon black, 2% of carbon nanotubes, and 7% of LA132 in pure water for Stir at a high speed for 2 hours at a stirring speed of 6000 r / min to prepare a positive electrode slurry. Then use the coating equipment to evenly coat the positive electrode slurry on both sides of the current collector aluminum foil, dry, roll and cut to obtain the positive electrode sheet, wherein the thickness of one side of the positive electrode material is 117 μm.

[0044]Dissolve 83% of LTO, 4% of activated carbon, 4% of conductive carbon black, 2% of carbon nanotubes, and 7% of LA132 in pure water, and perform high-speed stirring for 2 hours at a stirring speed of 6000r / min to make a negative electrode slurry. Then use the coating equipment to evenly coat the negative electrode slurry on both sides of the current collector aluminum foil, and after drying, rolling and cutting to obtain ...

Embodiment 2

[0047] Dissolve 80% LMO-NCM (the mass ratio of LMO and NCM is 3:7), 6% activated carbon, 4% conductive graphite, 3% carbon nanotubes, 2% LA132, 3.5% gelatin in pure In the water, high-speed stirring was performed for 1 hour at a stirring speed of 6000 r / min, and then 1.5% PAAS was added for high-speed stirring for 1 hour to prepare positive electrode slurry. Then use the coating equipment to evenly coat the positive electrode slurry on both sides of the current collector aluminum foil, dry, roll and cut to obtain the positive electrode sheet, wherein the thickness of one side of the positive electrode material is 117 μm.

[0048] Dissolve 80% of LTO, 6% of activated carbon, 4% of conductive graphite, 3% of carbon nanotubes, 2% of LA132, and 3.5% of gelatin in pure water, and carry out high-speed stirring for 1 hour at a stirring speed of 6000r / min , and then add 1.5% of PAAS and carry out high-speed stirring for 1 h to make negative electrode slurry. Then use the coating equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com