Transportation and sale freshness retaining method for treating navel oranges with non-woven cloth freshness retaining bags by fennel liquid

A fresh-keeping method and liquid processing technology, applied in the field of fruit and vegetable storage and fresh-keeping, can solve the problems of inability to remove harmful gases in time, fruit senescence and physiological diseases, increase fruit rot rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

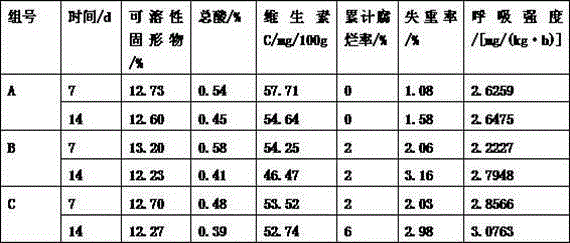

[0033] Gannan navel oranges picked at the end of November were selected as test materials with uniform size, uniform color, and no mechanical damage and pests. 450 test materials each, after cleaning, were treated with 3% fennel extract prepared by the above extraction method (specific embodiment 1) as group A, 3% clove extract as group B, and 3% cinnamon extract as group A. Group C, water treatment control group D, soaked for 3 to 5 minutes respectively, removed and drained, and left at room temperature for 1 to 2 days to allow the water on the skin surface to evaporate naturally. Single fruit packaged in polyethylene plastic film bags, stored in a common warehouse (20°C, RH 82%), the test results are shown in the table below.

[0034]

[0035] Through the test, 3% fennel, clove and cinnamon extracts all had antiseptic effects on navel oranges, and the rot rate at the later stage of storage was significantly lower than that of the control, and the soluble solids and vitami...

Embodiment 2

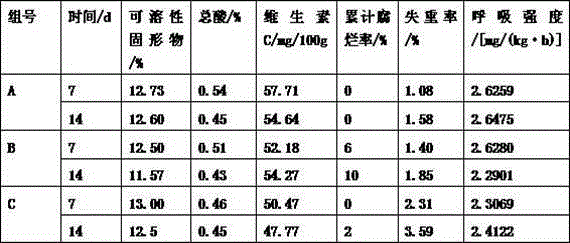

[0037] The Gannan navel oranges, which were picked at the end of November and stored at 4°C for 4 months, were used as test subjects. Fruits with uniform size, uniform color, and no mechanical damage, diseases and insect pests were selected. The non-woven fresh-keeping bags treated with methylcellulose are packaged as group A (i.e. the above-mentioned specific embodiment); the fruit is soaked with 3% fennel extract, and treated with 1% hydroxypropyl methylcellulose + 0.5% glycerin compound liquid coating film It is group B; the blank control is group C, and 450 test materials in each of the three groups are stored at room temperature (25°C, RH82%), and the fruit quality is tracked during the period.

[0038] results and analysis

[0039]

[0040] Through the test, the weight loss rate and rot rate of navel oranges in group A using the above-mentioned out-of-warehouse technology were extremely significantly (P<0.01) lower than those directly coated with film and the blank co...

Embodiment 3

[0042] Gannan navel oranges picked at the end of November and refrigerated at 4°C for 4 months were selected as test materials with uniform size, uniform color, and no mechanical damage and pests. 450 fruits per treatment.

[0043] A: Fruit soaked in 3% fennel extract, non-woven fresh-keeping bag (soaked in hydroxypropyl methylcellulose composite film solution) single fruit packaging treatment A.

[0044]The formula of hydroxypropyl methylcellulose composite membrane liquid is: 1% hydroxypropyl methylcellulose + 0.5% glycerin

[0045] B: Dipping fruit with 3% fennel extract, non-woven fresh-keeping bag (soaked in chitosan starch composite film solution) single fruit packaging treatment B.

[0046] The formula of chitosan starch composite film solution is: 1.5% chitosan solution + 3% acetic acid + 0.5% glycerin + 2% starch + 0.1% Tween

[0047] C: 3% fennel + 1.5% chitosan solution + 3% acetic acid + 0.5% glycerin + 2% starch + 0.1% Tween compound liquid coating treatment C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com