Folium mori powder biological complete feed and production method thereof

A technology of full-price feed and mulberry leaf powder, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of low apparent digestibility, poor palatability, unfavorable utilization of mulberry leaves for livestock and poultry, etc. Feed intake, nutritional balance, easy to grasp the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

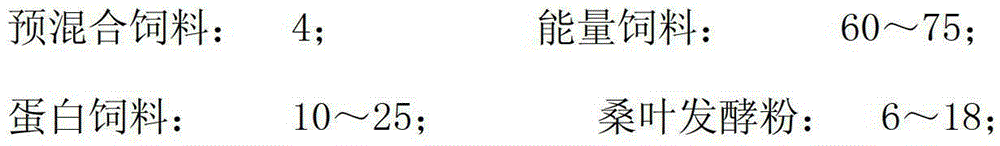

[0034] Embodiment 1: a kind of mulberry leaf powder biological complete feed, it is prepared from the raw material of following weight portion:

[0035]

[0036] Wherein, the premixed feed includes the following raw materials in parts by weight: stone powder: 30, calcium hydrogen phosphate: 30, salt: 5, L-lysine hydrochloride: 5, ferrous sulfate: 0.5, manganese sulfate: 0.3, Zinc sulfate: 0.3, copper sulfate: 0.1, menadione sodium bisulfite: 0.003, DL-α-tocopheryl acetate: 0.02, vitamin D3: 0.001, vitamin A acetate: 0.001;

[0037] The mulberry leaf fermentation powder includes the following raw materials in parts by weight: dried mulberry leaves: 80, soybean meal: 5, corn: 5, salt: 0.2, citric acid: 0.4, water: 77, strains: 2, and the strains are A mixed strain of Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum and Aspergillus oryzae; the concentration of each strain in the strains is as follows: Bacillus subtilis is 1.0×10 9 CFU / g, Saccharomyces cere...

Embodiment 2

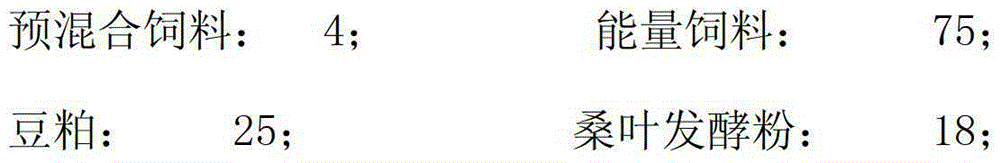

[0038] Embodiment 2: a kind of mulberry leaf powder biological complete feed, it is prepared from the raw material of following weight portion:

[0039]

[0040] Wherein, the premixed feed includes the following raw materials in parts by weight: stone powder: 45, calcium hydrogen phosphate: 40, salt: 10, L-lysine hydrochloride: 11, ferrous sulfate: 1.5, manganese sulfate: 0.8, Zinc sulfate: 0.8, copper sulfate: 0.5, sodium bisulfite menadione: 0.006, DL-α-tocopheryl acetate: 0.08, vitamin D3: 0.005, vitamin A acetate: 0.005; the mulberry leaf fermentation The powder includes the following raw materials in parts by weight: dried mulberry leaves: 90, soybean meal: 10, corn: 8, salt: 0.5, citric acid: 0.6, water: 85, strains: 4, and the strains are Bacillus subtilis, Saccharomyces cerevisiae A mixed strain of yeast, Lactobacillus plantarum and Aspergillus oryzae; the concentration of each strain in the strains is as follows: Bacillus subtilis is 1.5×10 9 CFU / g, Saccharomyces ...

Embodiment 3

[0041] Embodiment 3: a kind of mulberry leaf powder biological complete feed, it is prepared from the raw material of following weight portion:

[0042]

[0043]Wherein, the premixed feed includes the following raw materials in parts by weight: stone powder: 32, calcium hydrogen phosphate: 33, salt: 6, L-lysine hydrochloride: 6, ferrous sulfate: 0.7, manganese sulfate: 0.4, Zinc sulfate: 0.4, copper sulfate: 0.2, menadione sodium bisulfite: 0.0032, DL-α-tocopheryl acetate: 0.03, vitamin D3: 0.004, vitamin A acetate: 0.002;

[0044] The mulberry leaf fermentation powder includes the following raw materials in parts by weight: dry mulberry leaves: 82, soybean meal: 6, corn: 6, salt: 0.3, citric acid: 0.45, water: 80, strains: 2.5, and the strains are Mixed strains of Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum and Aspergillus oryzae; Bacillus subtilis is 1.5×10 9 CFU / g, Saccharomyces cerevisiae is 1.5×10 8 CFU / g, Lactobacillus plantarum is 1.8×10 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com