Cleaning agent suitable for cleaning hollow fiber nanofiltration membranes and preparation method thereof

A nanofiltration membrane and cleaning agent technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as damage to membrane elements, achieve reduced cleaning frequency, fast and efficient permeation flux, and restore permeation flux. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

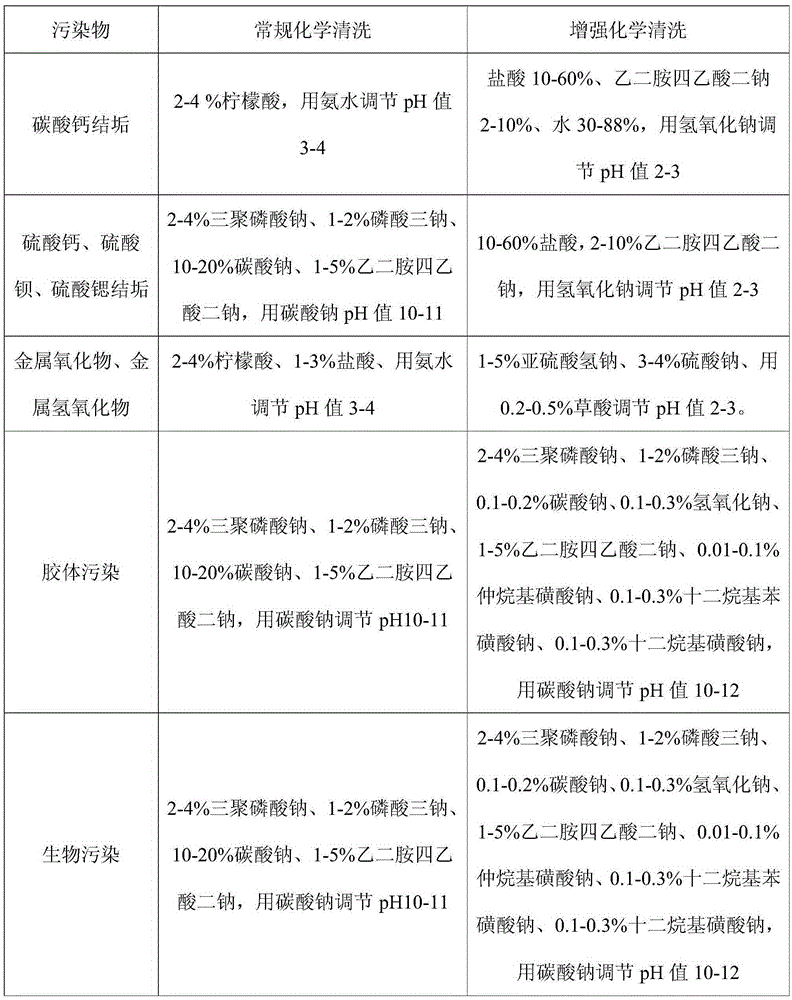

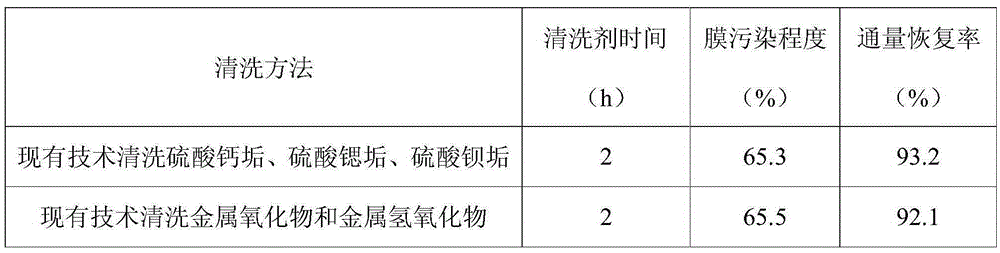

Method used

Image

Examples

Embodiment 1

[0035] By weight percentage, 2% citric acid and 98% water are successively added in an enamel reactor with a stirring function, stirred at room temperature for 1-3 hours, and the pH value is adjusted with volumetric concentration of 20% ammonia water to make it It is 3, promptly get the medium fiber nanofiltration membrane cleaning agent that is suitable for cleaning calcium carbonate scale pollution.

Embodiment 2

[0037] According to the percentage by weight, 3% sodium tripolyphosphate, 1% trisodium phosphate, 10% sodium carbonate, 1% disodium edetate, and 85% water are added to an enamel reactor with stirring function , stir at room temperature for 1-3 hours, and use sodium carbonate with a pH value of 10 to obtain a medium-fiber nanofiltration membrane cleaning agent suitable for cleaning calcium sulfate scale, strontium sulfate scale, and barium sulfate scale pollution.

Embodiment 3

[0039] By weight percentage, 40% hydrochloric acid (content 31%), 2% disodium ethylenediamine tetraacetate, 58% water are successively added in an enamel reactor with a stirring function, and stirred at room temperature for 1-3 hours , adjust the pH value to 2.5 with sodium hydroxide to obtain a medium fiber nanofiltration membrane cleaning agent suitable for cleaning calcium carbonate scale, calcium sulfate scale, strontium sulfate scale, and barium sulfate scale pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com