A biological and chemical coupling sludge conditioning method

A sludge conditioning and sludge mixing technology, which is applied in the field of environmental engineering, can solve the problems of high cost, poor sludge dehydration effect, long cycle, etc., achieve long biological reaction cycle, improve coagulation and adsorption efficiency, and dosing A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

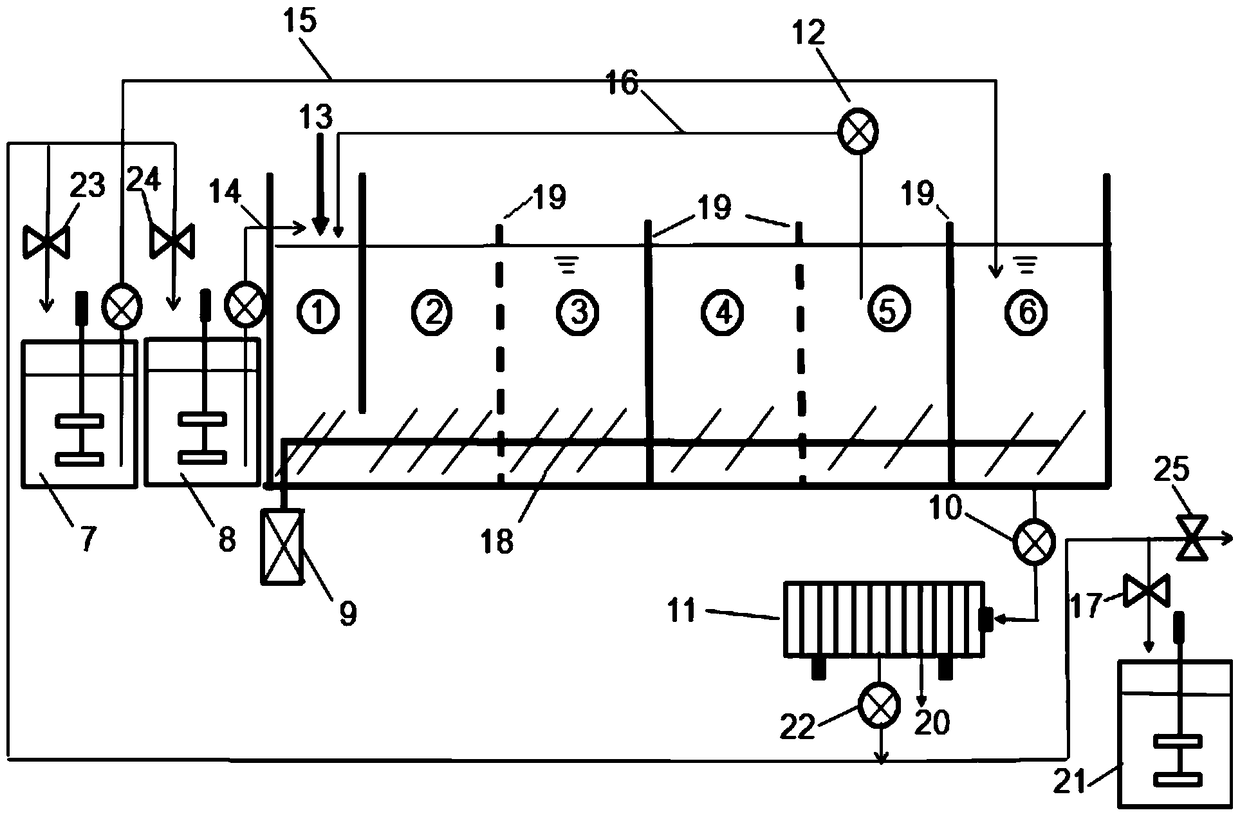

[0019] Specific implementation mode one: combine figure 1 Description of this embodiment, the biological and chemical coupling sludge conditioning method of this embodiment is carried out according to the following steps:

[0020] 1. The material to be treated enters the contact zone 1 through the feed pipe 13, and the mixed sludge in the fifth reaction zone 5 enters the contact zone 1 through the sludge return pump 12 and the sludge return pipe 16, and at the same time, the mixed sludge in the stirring tank 8 of the agent A The mixed solution of agent A enters the contact zone 1 through the agent A dosing pipe 14, and the mixed solution of the material to be treated, the return sludge and the agent A forms mixed sludge under the action of air agitation in the contact zone 1, and the mixed sludge enters from the bottom of the partition The second reaction zone 2 then bypasses the baffle plate 19 and enters the third reaction zone 3, the fourth reaction zone 4 and the fifth rea...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that step 1 medicament A: every kg consists of 50-300g nanometer sulfur powder, 200-400g ferrous sulfate, 100-200g ferric chloride, 100-1000mg vitamin A, 1-5g zinc chloride, 5-50g potassium dihydrogen phosphate, 50-150g thermally modified diatomite, 5-50g glucose, 5-50g animal glue and 2-50g surfactant. Other steps and parameters are the same as those in Embodiment 1.

[0025] In this embodiment, the heat-modified diatomite is to heat the diatomite at 200° C.-500° C. for 1-5 hours.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment is different from Embodiment 2 in that the surfactant is one or any combination of stearic acid, quaternary ammonium salt, and polysorbate. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com