Functional protecting surface material with good adhesive performance and preparation method for function protecting surface material

A surface material, ethyl technology, applied in the field of materials, can solve problems such as unpublished reports, achieve good protection performance, simple process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

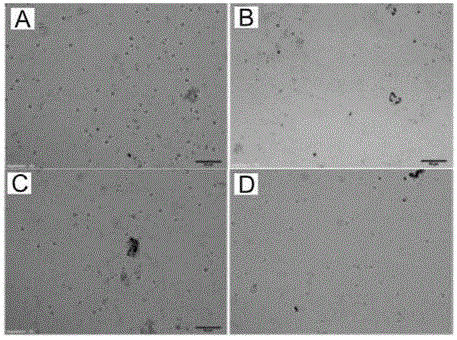

Image

Examples

Embodiment 1

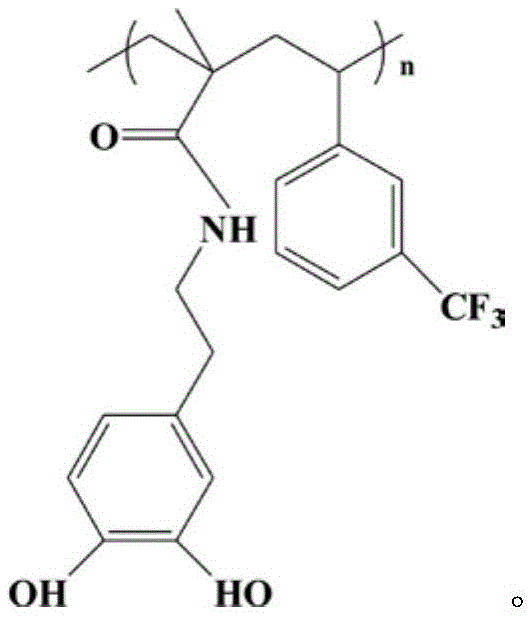

[0026] N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer, the structural formula of the copolymer is:

[0027]

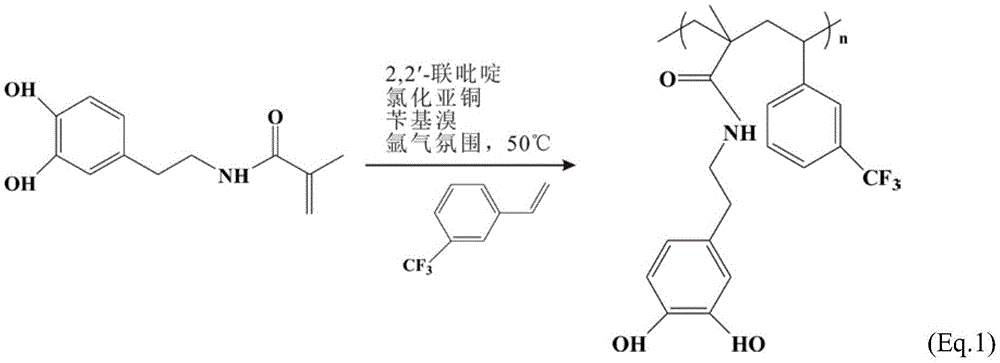

[0028] N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer is prepared by the following method: ① In parts by weight, weigh 3 parts of 3-(trifluoromethyl)styrene , 0.2 parts of N-(3,4-dihydroxyphenyl) ethyl-methacrylamide, 0.03 parts of cuprous chloride, 0.4 parts of 2,2′-bipyridyl, 0.03 parts of benzyl bromide; For the treated toluene, argon gas was passed through it for 15 minutes; the materials prepared in step ① were added to the toluene, and stirred and reacted for 6 hours under the protection of argon at a temperature of 50° C.; the reaction equation is shown in Eq.1. ③ Evaporate the solution after the reaction in step ②, and then wash it with methanol and acetone for 4 times to remove the solvent attached to the surface of the precipitate to obtain the product. Each part by weight is 10 g.

[0029]

[0030] The reaction mechanism of preparing ...

Embodiment 2

[0033] The difference from Example 1 is that the N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer is prepared by the following method: ① In parts by weight, weigh 4 parts of 3- (Trifluoromethyl)styrene, 0.3 part of N-(3,4-dihydroxyphenyl)ethyl-methacrylamide, 0.06 part of cuprous chloride, 0.1 part of 2,2′-bipyridyl, 0.04 part Benzyl bromide; ②Take the pre-dried toluene, and blow it with argon for 5 minutes; add the materials prepared in step ① into toluene, and stir for 8 hours under the protection of an inert gas atmosphere at a temperature of 60°C. ③ Evaporate the solution after the reaction in step ②, and then wash it twice with methanol and acetone respectively to remove the solvent attached to the surface of the precipitate to obtain the product.

[0034] The preparation method of the functional protective surface material with good adhesion properties comprises the following steps: ① Weigh an appropriate amount of N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copol...

Embodiment 3

[0036] The difference from Example 1 is that the N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer is prepared by the following method: ① In parts by weight, take 5 parts of 3- (Trifluoromethyl)styrene, 0.4 parts of N-(3,4-dihydroxyphenyl)ethyl-methacrylamide, 0.01 parts of cuprous chloride, 0.2 parts of 2,2′-bipyridyl, 0.05 parts Benzyl bromide; ② Take the pre-dried toluene and blow it with argon for 10 minutes; add the materials prepared in step ① to toluene, and stir for 1 hour under the protection of an inert gas atmosphere at a temperature of 70°C. ③ Evaporate the solution after the reaction in step ②, and then wash it three times with methanol and acetone respectively to remove the solvent attached to the surface of the precipitate to obtain the product.

[0037] The preparation method of the functional protective surface material with good adhesion properties comprises the following steps: ① Weigh an appropriate amount of N-(3,4-dihydroxyphenyl) ethyl-methacrylamid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com