A dispersant for two-phase fermentation system

A technology of dispersant and chelating agent, applied in the field of two-phase fermentation, can solve the problems of easy agglomeration, low conversion efficiency and yield, etc., and achieves the effect of solving agglomeration, reducing stirring and dispersing time, and having strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

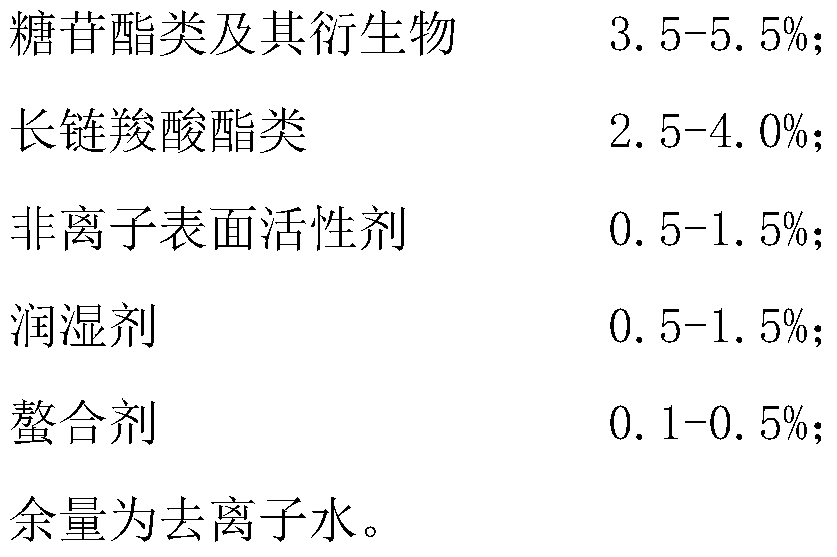

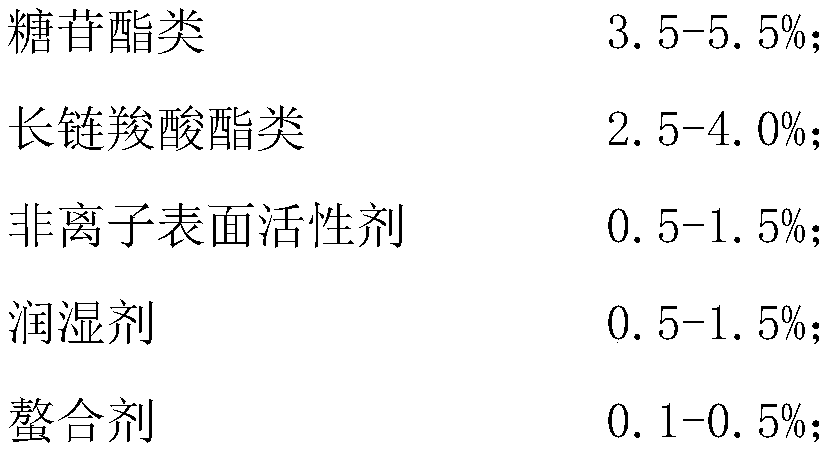

Method used

Image

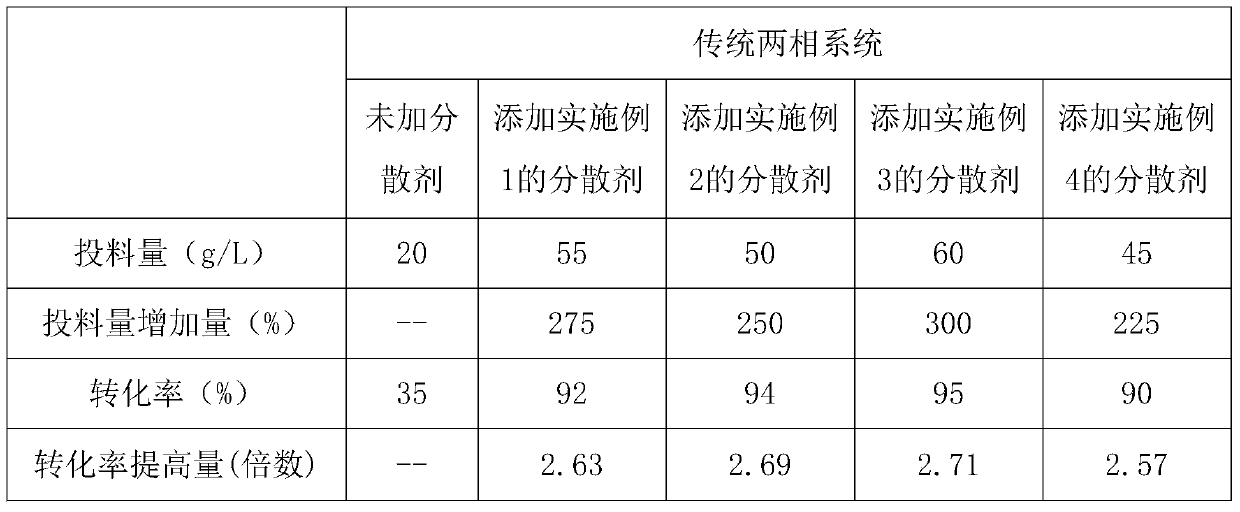

Examples

Embodiment 1

[0033] (1) Take 35g of methyl glucoside myristate, 40g of propyl alkyl carboxylate, 10g of fatty alcohol polyoxyethylene ether AEO-9, 5g of propylene glycol, 1g of EDTA-2Na, and 909g of water for subsequent use;

[0034] (2) Add methyl glucoside myristate, propyl alkyl carboxylate, AEO-9, and propylene glycol into a high-speed shearing machine and shear at a high speed to obtain a microemulsion with a particle size of about 300nm. Dissolve EDTA-2Na in water, dissolve evenly, add into the microemulsion, stir at 550r / min at high speed for 35min, and raise the temperature to 45°C at the same time; then stir at 100r / min at low speed for 30min, cool and filter to obtain the dispersant microemulsion of the present invention.

Embodiment 2

[0036] (1) Take 45g of sucrose ester SE-10, 35g of alkyl carboxylate heptyl ester, 15g of alkyl glycoside APG0810, 10g of butanediol, 5g of N-oleoyl sarcosine, and 890g of water for later use;

[0037] (2) Add sucrose ester SE-10, heptyl alkyl carboxylate, alkyl glycoside APG0810, and butanediol into a high-speed shearing machine and shear evenly at high speed to obtain a microemulsion with a particle size of about 250 nm. Dissolve N-oleoyl sarcosine in water, dissolve evenly, add it into the microemulsion, stir at 500r / min at high speed for 30min, and at the same time raise the temperature to 50°C; then stir at 120r / min at low speed for 30min, cool and filter to obtain the dispersion of the present invention agent microemulsion.

Embodiment 3

[0039] (1) Get 55g of sucrose ester SE-13, 25g of methyl phenol carboxylate, 5g of sorbitan ester-60, 15g of glycerol, 3g of EDTA-2Na, and 897g of water for subsequent use;

[0040](2) Add sucrose ester SE-13, methyl alkylphenol carboxylate, sorbitan ester-60, and glycerol into a high-speed shearing machine and shear at a high speed to obtain a microemulsion with a particle size of about 450 nm. Dissolve EDTA-2Na in water, dissolve evenly, add into the microemulsion, stir at 600r / min at high speed for 40min, and at the same time raise the temperature to 50°C; then stir at 150r / min at low speed for 30min, cool and filter to obtain the dispersant microemulsion of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com