Preparation method of p-type tin dioxide thin film capable of realizing near-band-edge ultraviolet luminescence

A technology of tin dioxide and thin film, which is applied in the field of preparation of p-type SnO2 thin film, can solve the problems of low solid solubility, reduce acceptor ionization energy, etc., and achieve the effect of improving solid solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

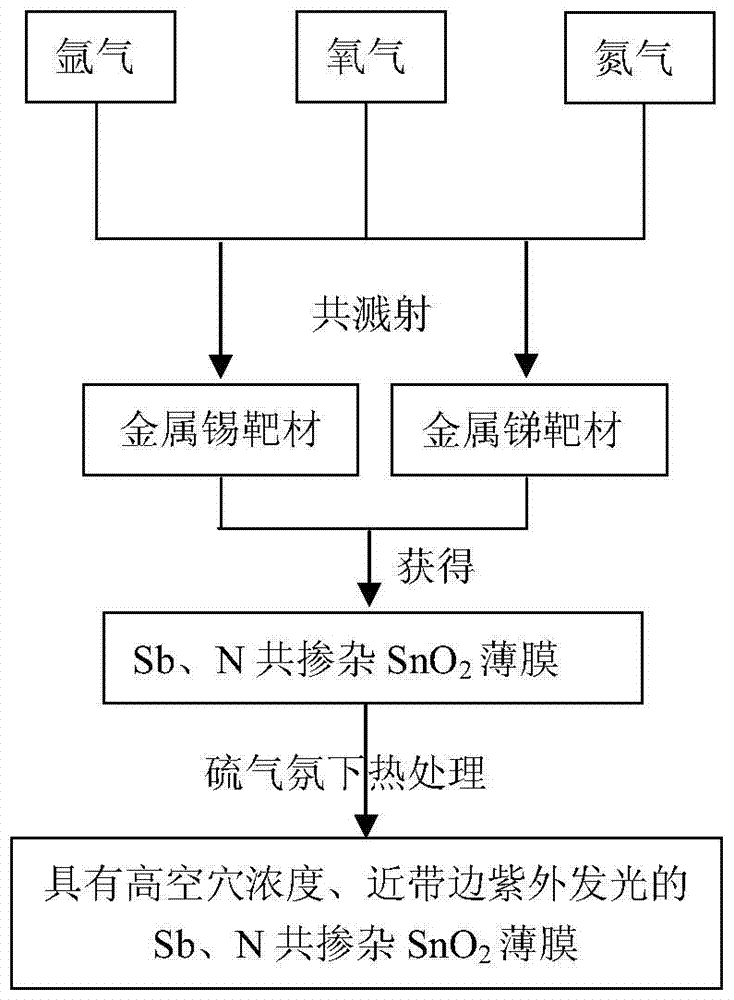

Method used

Image

Examples

Embodiment

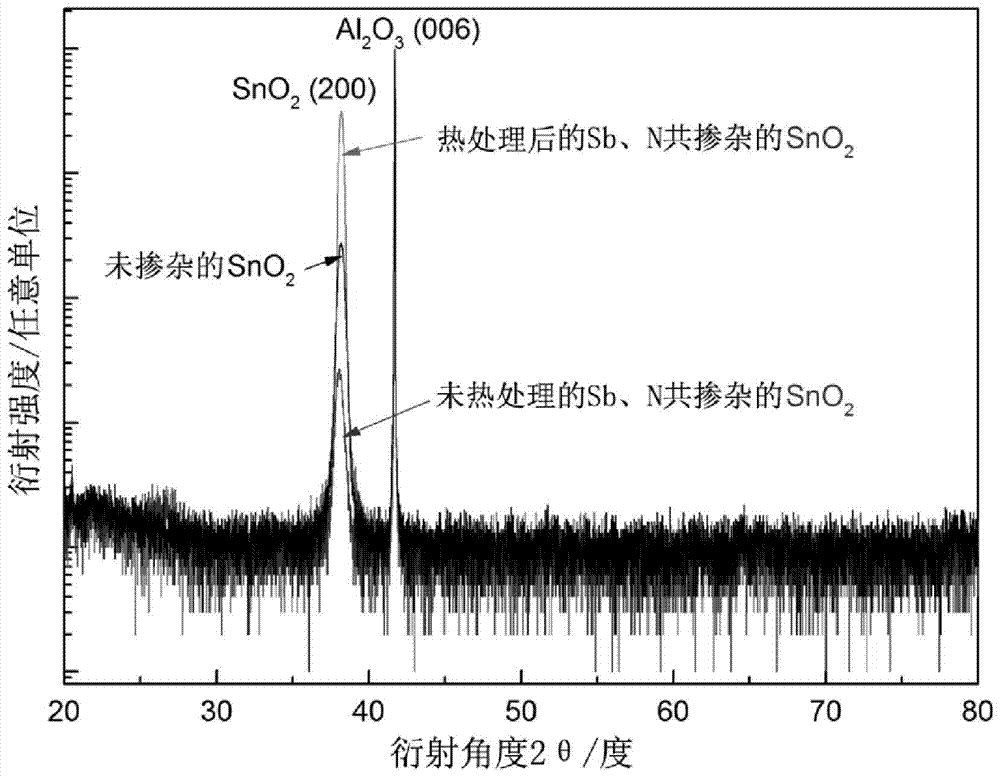

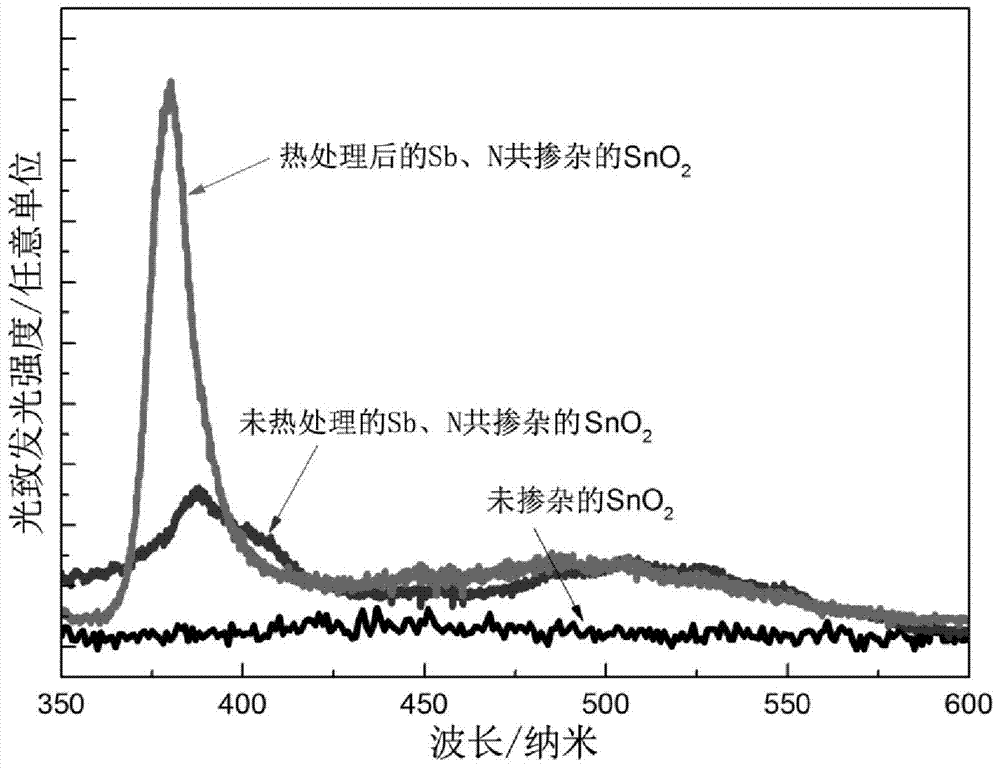

[0012] Install metal tin and metal antimony with a diameter and thickness of 60mm and 3mm respectively on the two target positions of the magnetron sputtering equipment, put the c-plane sapphire on the heating furnace (sample holder) of the growth chamber, and vacuum the system Air pressure pumped to 1×10 -4 Pa, heat the sapphire substrate to 300°C, feed a mixed gas of argon, oxygen and nitrogen with a volume ratio of 1:2:1, the gas flow rate is 40SCCM, adjust the pressure in the growth chamber to 1Pa, and place the tin target and the antimony target Adjust the sputtering power to 70W and 25W respectively, remove the two target baffles, and sputter for 60 minutes to obtain unheated Sb and N co-doped SnO 2 film. Put the film in an annealing furnace, and put 30mg of sulfur powder evenly around the film, use a vacuum pump to pump the annealing furnace pressure below 0.1Pa, and then pass in argon gas with a gas flow rate of 40 SCCM, and raise the temperature at a rate of 5°C / s A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com