Lithium-sulfur battery with composite structure

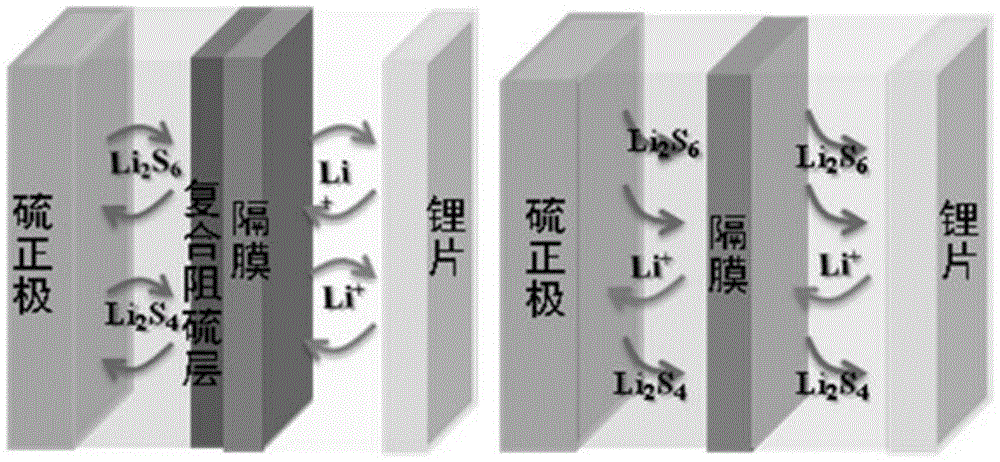

A lithium-sulfur battery and composite technology, applied in the direction of lithium batteries, structural parts, battery pack components, etc., can solve the problems of limiting the full discharge of the battery, affecting the discharge capacity of the battery, and failing to meet actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

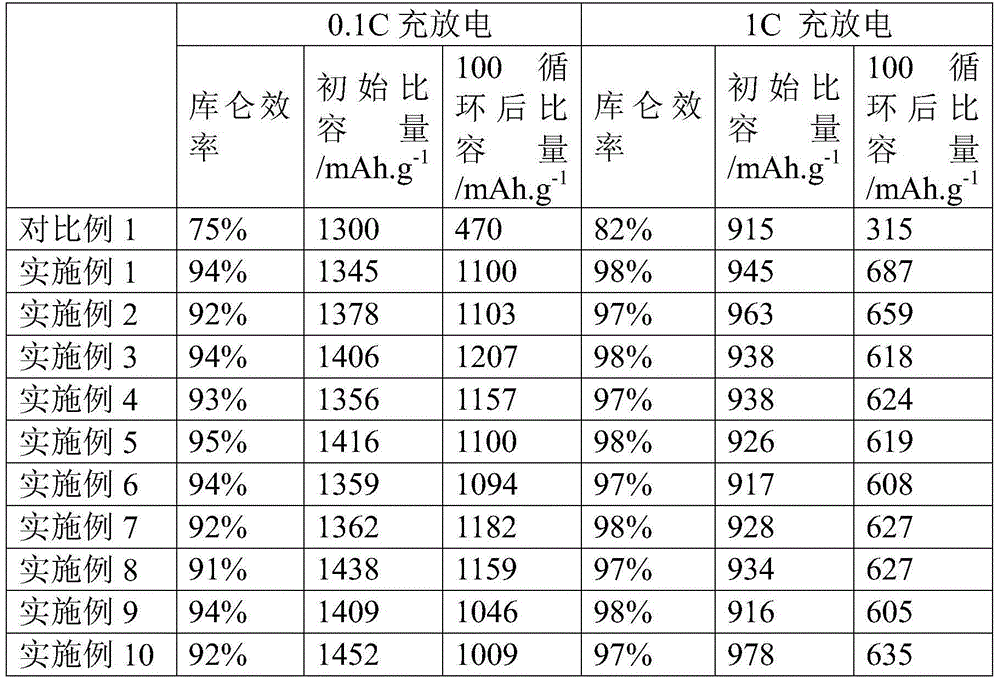

Embodiment 1

[0019] 1 mass fraction of TiS 2 Disperse evenly in 10 parts by mass of ethanol, and TiS 2 Spray the dispersion liquid on the polypropylene diaphragm, dry and remove water for later use.

[0020] The negative electrode of a lithium-sulfur battery is a lithium foil with a thickness of 20 microns. The positive electrode is prepared by the following method: 20 parts by mass of SuperP carbon, 70 parts by mass of elemental sulfur, and 10 parts by mass of polyvinylidene fluoride (PVDF) blended in N-methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.0 mg / cm2. The electrolyte solution is a solution of lithium bis(trifluoromethylsulfonyl)imide, the solvent is ethylene glycol dimethyl ether / dioxolane (volume ratio 1:1), and the concentration of the electrolyte is 1mol / L. The above components are used as positive electrode / separator (containing TiS 2 coating) / the layered structure of the negative electrode ...

Embodiment 2

[0024] Preparation of composite sulfur barrier layer: 1 mass fraction of MoS 2 1. 1 mass fraction of graphene is uniformly dispersed in 15 mass fractions of isopropanol, and the above dispersion is suction-filtered to form a solid film, and dried for later use.

[0025] The negative electrode of a lithium-sulfur battery is a lithium foil with a thickness of 20 microns. The positive electrode is prepared by the following method: 20 parts by mass of SuperP carbon, 70 parts by mass of elemental sulfur, and 10 parts by mass of polyvinylidene fluoride (PVDF) blended in N-methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.0 mg / cm2. The electrolyte solution is a solution of lithium bis(trifluoromethylsulfonyl)imide, the solvent is ethylene glycol dimethyl ether / dioxolane (volume ratio 1:1), and the concentration of the electrolyte is 1mol / L. The above-mentioned components were assembled together in a lay...

Embodiment 3

[0027] Preparation of composite sulfur barrier layer: 1 mass fraction of WS 2 1. 1 mass fraction of graphene is uniformly dispersed in 15 mass fractions of isopropanol, and the above dispersion is suction-filtered to form a solid film, and dried for later use.

[0028] The negative electrode of a lithium-sulfur battery is a lithium foil with a thickness of 20 microns. The positive electrode is prepared by the following method: 20 parts by mass of SuperP carbon, 70 parts by mass of elemental sulfur, and 10 parts by mass of polyvinylidene fluoride (PVDF) blended in N-methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.0 mg / cm2. The electrolyte solution is a solution of lithium bis(trifluoromethylsulfonyl)imide, the solvent is ethylene glycol dimethyl ether / dioxolane (volume ratio 1:1), and the concentration of the electrolyte is 1mol / L. The above-mentioned components were assembled together in a laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com