Composite nanofiber air filtration material and preparation method thereof

An air filter material and composite nanofiber technology, which is applied in the field of composite nanofiber air filter material and its preparation, can solve the problems of composite membranes not being tightly bonded, poor filtering effect, and high airflow resistance, and achieve tight composite membrane bonding and airflow resistance Low, small pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The polyvinyl alcohol (PVA) powder that takes by weighing 1.8g is dissolved in 18.2g deionized water, and accelerates dissolving under 90oC constant temperature magnetic stirring, the PVA spinning solution that the preparation obtains mass percentage is 9%; Weighs 1.4g polyacrylonitrile ( PAN) (molecular weight: 90,000) powder was dissolved in 18.6g of dimethylformamide solvent, and the dissolution was accelerated under constant temperature magnetic stirring at 70°C to prepare a PAN spinning solution with a mass percentage of 7%.

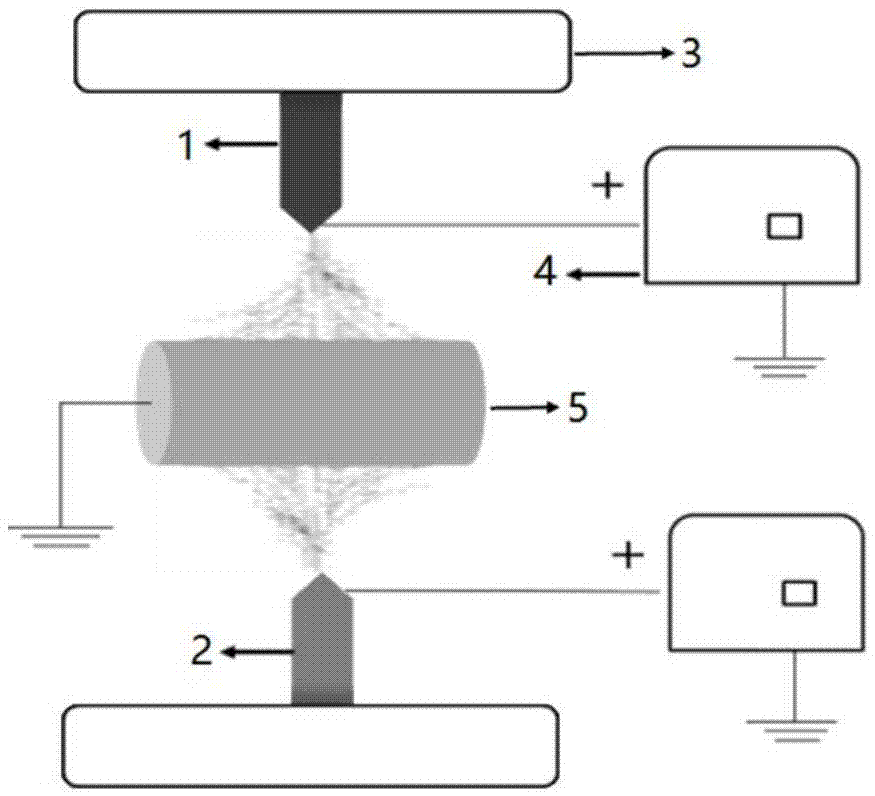

[0022] Pour the above-mentioned PVA spinning solution and the PAN spinning solution into the liquid storage cylinders communicating with the two spinning nozzles 1 and 2 respectively (such as figure 1 Shown), the nozzle place is connected with copper wire, and the 300 mesh stainless steel wire mesh is placed on the metal receiving cylinder 5. First open the PVA spinning solution separately for spinning, the spinning voltage is 10KV, the spinn...

Embodiment 2

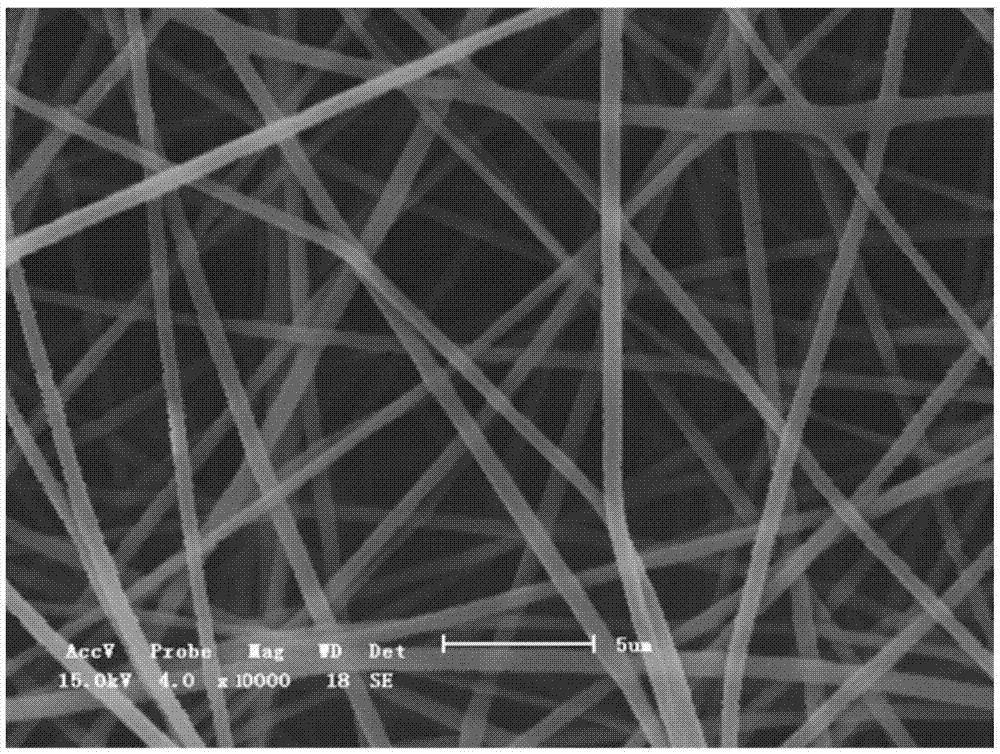

[0026] By the way of Example 1, the difference is that 2.4g of PVA powder is dissolved in 17.6g deionized water to make a PVA spinning solution with a mass percentage of 12%; 2.4g of PAN (molecular weight is 80,000) powder is dissolved in 17.6g In the dimethylformamide solvent, the PAN spinning solution with a mass percentage of 12% was prepared. Other processing conditions are all with embodiment 1. A composite fiber air filter material with a dense structure and stable performance is obtained with a thickness of 65 μm. Among them, the diameter of PVA fiber is 940±35nm, and the diameter of PAN fiber is 415±30nm. image 3 It is the surface electron microscope scanning picture of the composite nanofiber air filter material.

[0027] The complete porosity of the composite nanofiber air filter material is 76.2%, the average pore diameter is 4.20 μm, the filtration efficiency of NaCl aerosol with a number median diameter of 75nm reaches 99.98%, and the pressure drop is 560Pa.

Embodiment 3

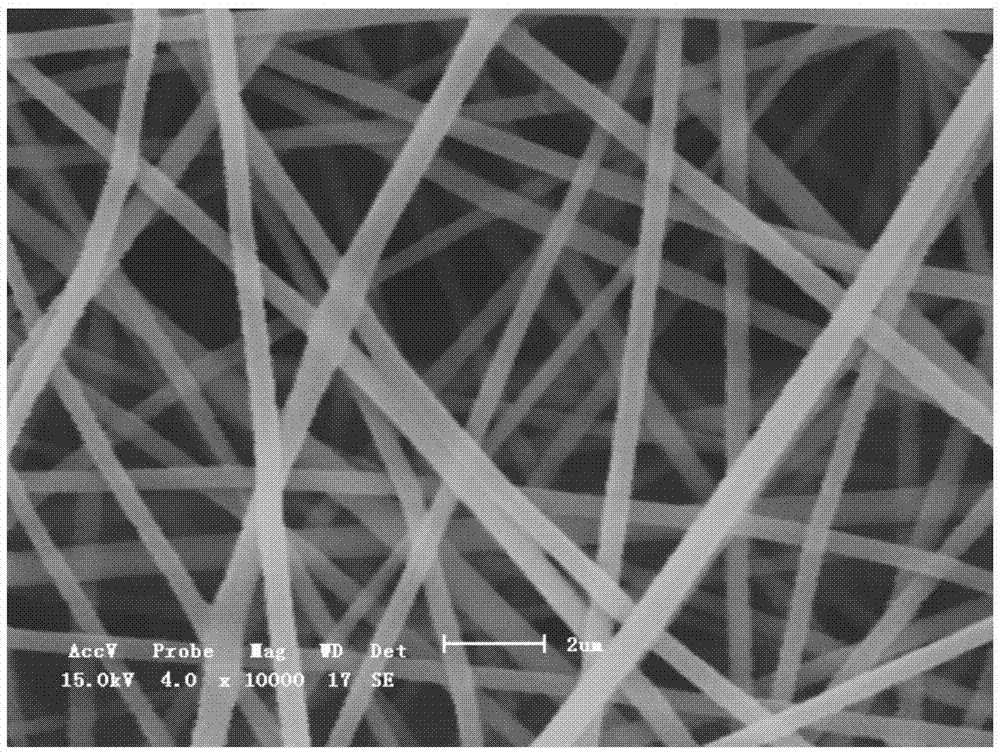

[0029] According to Example 1, the difference is that 2.8g of PVA powder is dissolved in 17.2g of deionized water to obtain a PVA spinning solution with a mass percentage of 14%; 2.8g of PAN (molecular weight is 90,000) powder is dissolved in 17.2 In g dimethylformamide solvent, a PAN spinning solution with a mass percentage of 14% was prepared. Other processing conditions are all with embodiment 1. A composite nanofiber air filter material with a dense structure and stable performance is obtained with a thickness of 85 μm. Among them, the diameter of PVA fiber is 950±50nm, and the diameter of PAN fiber is 392±45nm. Figure 4 It is a scanning electron microscope picture of the composite fiber air filter material.

[0030] The composite nanofiber air filter material has a complete porosity of 86.2%, an average pore diameter of 5.50 μm, a filtration efficiency of 99.97% for NaCI aerosols with a median diameter of 75 nm, and a pressure drop of 516 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com