Pollution gas treatment system and treatment method

A technology for polluting gas and treatment systems, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., to achieve stable operation, high selectivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

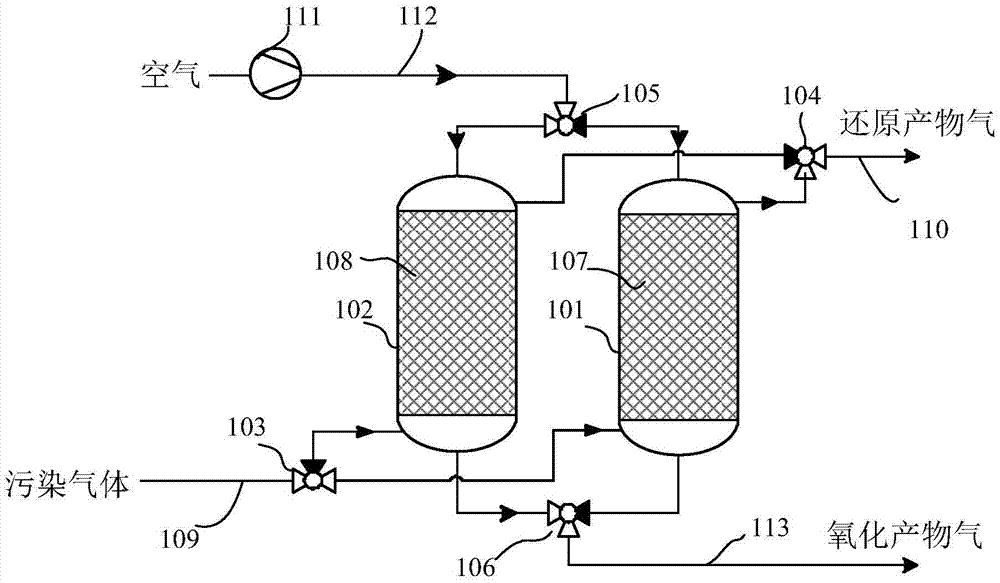

[0033] Please refer to figure 1 . The pollution gas treatment system shown includes: the first chemical looping combustion reactor 101 filled with the oxidation state 107 of the copper-based oxygen carrier, and the second chemical looping combustion reactor filled with the reduced state 108 of the copper-based oxygen carrier 102. Pollution gas pipeline 109, air blower 111, air pipeline 112, reduction reaction product gas pipeline 110, oxidation reaction product gas pipeline 113, and electric three-way valve groups 103-106. The active substance of the copper-based oxygen carrier is CuO, and the carrier is SiO 2. The polluting gas contains NH 3 .

[0034] The polluted gas enters the first chemical looping combustion reactor 101 through the three-way valve 103 on the polluted gas pipeline 109, and undergoes a reduction reaction with the oxidized oxygen carrier 107: the NH in the polluted gas 3 React with the oxidized oxygen carrier 107 to generate nitrogen and water vapor, w...

Embodiment 2

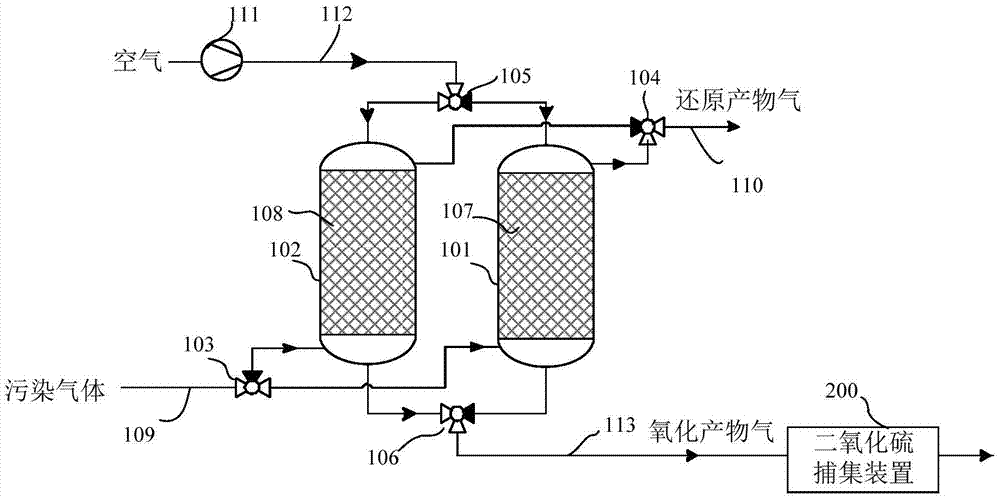

[0043] Please refer to figure 2 . Compared with Example 1, this embodiment differs in that: the oxygen carrier is an iron-based oxygen carrier, and its active material is Fe 2 o 3 , the carrier is Al 2 o 3 . The temperature of reduction reaction and oxidation reaction is 300°C. A sulfur dioxide capture device 200 is arranged on the oxidation reaction product gas pipeline 113 to capture SO in the oxidation reaction product gas 2 , the sulfur dioxide capture device 200 is a wet desulfurization device using limestone or lime slurry as a desulfurizing agent. Pollution gas contains trimethylamine and H 2 S.

[0044] Oxidation states of iron-based oxygen carriers with trimethylamine and H 2 The reduction reaction of S, and the reduced state and iron sulfide with O 2 The reaction equation of the oxidation regeneration reaction and the standard free energy change and reaction heat at the reaction temperature are as follows:

[0045] 63Fe 2 o 3 +2C 3 h 9 N(g)=42Fe 3 o ...

Embodiment 3

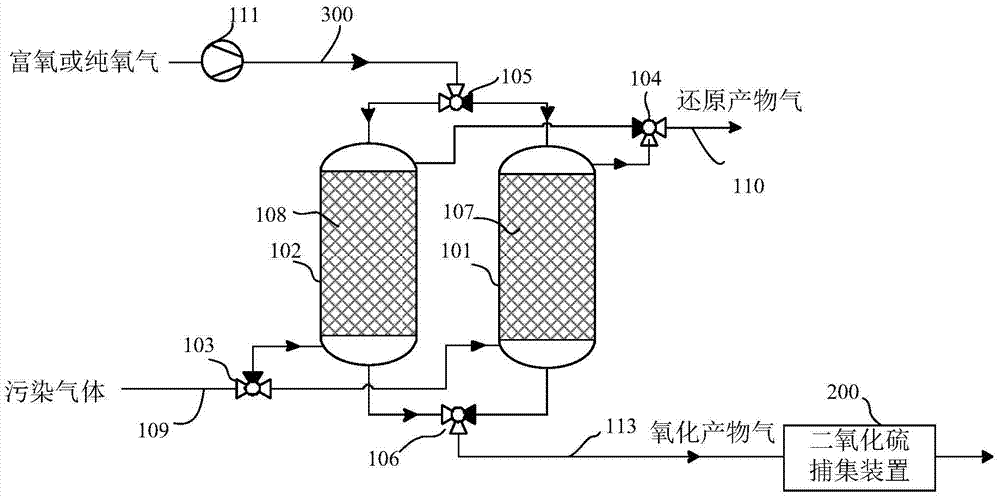

[0053] Please refer to figure 2 . Compared with Example 2, this embodiment differs in that: the oxygen carrier is a nickel-based oxygen carrier, its active material is NiO, and the carrier is TiO 2 . The temperature of the reduction reaction and the oxidation reaction is 350°C, and a sulfur dioxide capture device 200 is installed on the oxidation reaction product gas pipeline 113 to capture SO in the oxidation reaction product gas 2 , the sulfur dioxide trapping device 200 is a dry desulfurization device using calcium oxide as a desulfurizing agent. The polluting gas contains methyl mercaptan and toluene.

[0054] Reduction reactions of the oxidized state of nickel-based oxygen carriers with methyl mercaptan and toluene, and the reduced state and nickel sulfide with O 2 The reaction equation of the oxidation regeneration reaction and the standard free energy change and reaction heat at the reaction temperature are as follows:

[0055] 4NiO+CH 3 SH(g)=NiS+3Ni+CO 2 +2H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com