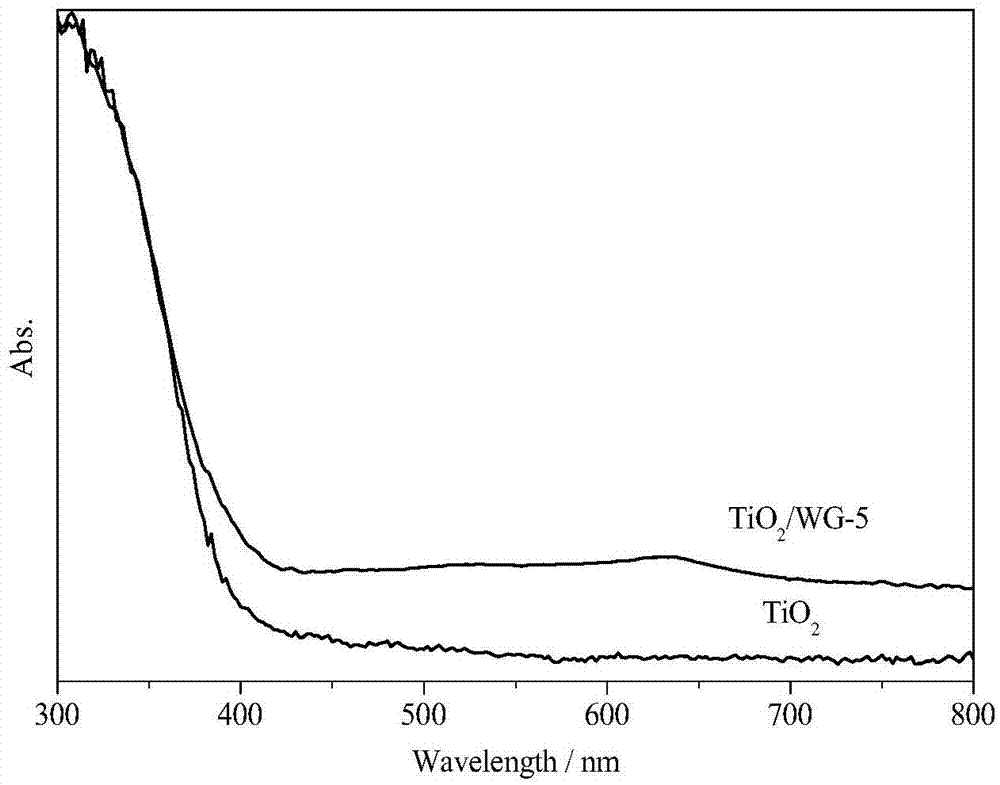

Preparation method for ternary-system TiO2/WS2/g-C3N4 composite photocatalyst with visible-light activity

A ternary system, g-c3n4 technology, used in physical/chemical process catalysts, chemical instruments and methods, light water/sewage treatment, etc. Harsh and other problems, to achieve the effect of promoting separation efficiency, good photocatalytic activity and visible light utilization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

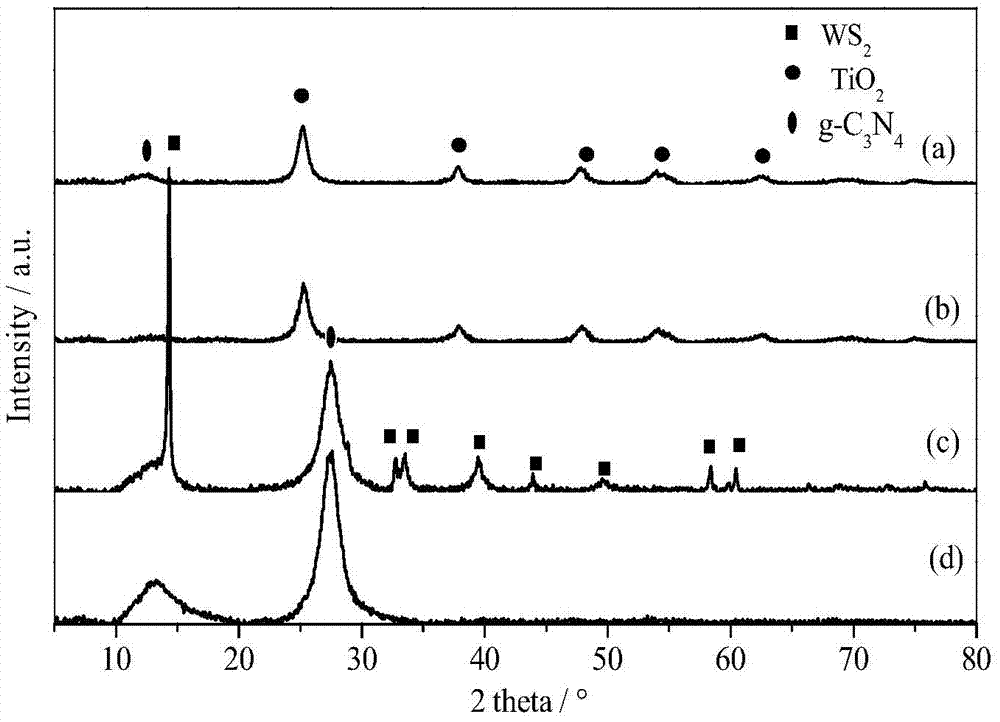

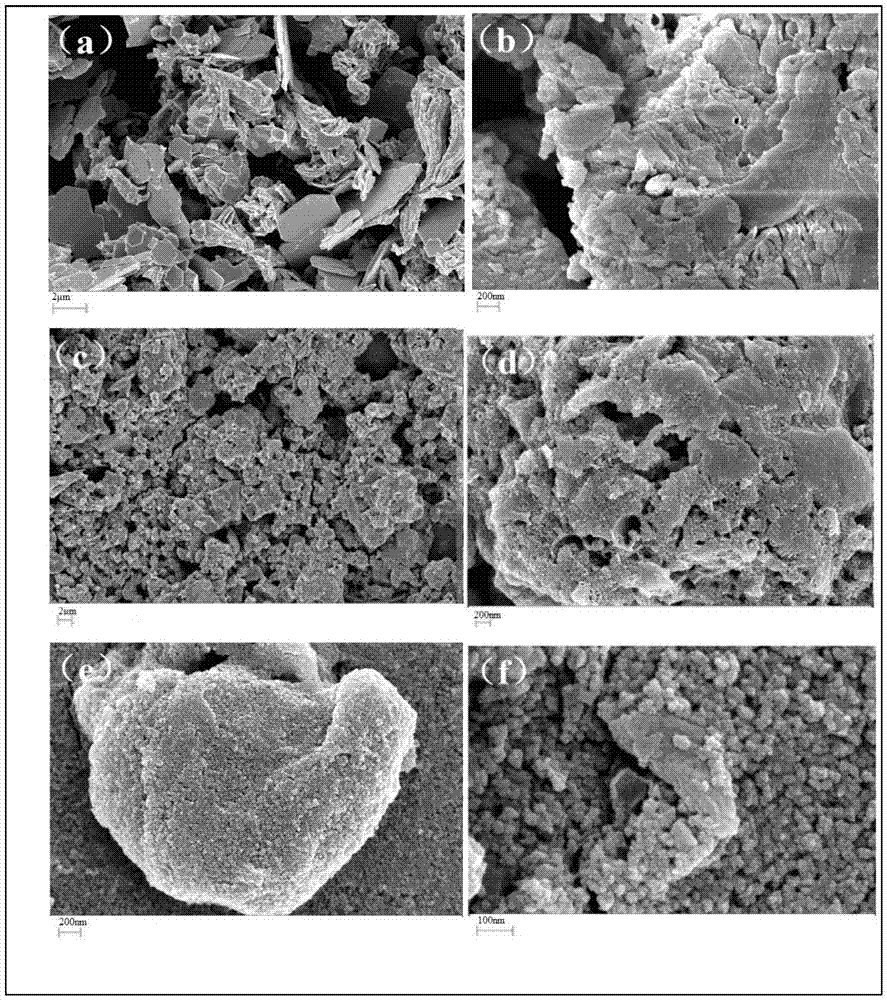

[0029] (1) Put 2.5g of thiourea and 2.5g of dicyandiamide into a mortar and grind thoroughly to obtain a uniform mixture, place the mixture in a muffle furnace at 500°C for calcination for 1 hour, then raise the temperature to 550°C and continue calcining for 2 hours, naturally Cool to room temperature, after grinding, obtain graphene-like carbon nitride (g-C 3 N 4 ).

[0030] (2) Add 0.02gWS with a mass ratio of 4.0% to 25mL hydrochloric acid ethanol solution (hydrochloric acid volume fraction is 12%) 2 (average particle size is 6μm) and 0.5gg-C 3 N 4 , sonicated for 20 min to obtain a dispersion. Transfer the dispersion liquid to a 25mL hydrothermal reaction kettle, and hydrothermally treat it in an oven at 80°C for 10 hours. get WS 2 / g -C 3 N 4 Complex.

[0031] (3) Prepare 16mL of 0.4mol / L TiCl 4 Ethanol solution in a 100mL beaker, according to WS 2 / g -C 3 N 4 :TiO 2 =5wt% Add 0.032g of WS to the ethanol solution 2 / g -C 3 N 4 The composite was ultrasoni...

Embodiment 2

[0035] (1) Put 2.5g of thiourea and 2.5g of dicyandiamide into a mortar and grind thoroughly to obtain a homogeneous mixture, place the mixture in a muffle furnace at 500°C for 1h, then heat up to 550°C for 2h, and cool naturally To room temperature, after grinding, obtain graphene-like carbon nitride (g-C 3 N 4 ).

[0036] (2) Add 0.02gWS with a mass ratio of 4.0% to 25mL hydrochloric acid ethanol solution (hydrochloric acid volume fraction is 12%) 2 (average particle size is 6μm) and 0.5gg-C 3 N 4 , sonicated for 20 min to obtain a dispersion. Transfer the dispersion liquid to a 25mL hydrothermal reaction kettle, and hydrothermally treat it in an oven at 80°C for 10 hours. WS available 2 / g -C 3 N 4 Complex.

[0037] (3) Prepare 16mL of 0.4mol / L TiCl 4 Ethanol solution in a 100mL beaker, according to WS 2 / g -C 3 N 4 :TiO 2 =7wt% Add 0.045g of WS to the ethanol solution 2 / g -C 3 N 4 The complex was ultrasonicated for 60 min at room temperature to obtain a m...

Embodiment 3

[0041] (1) Put 2.5g of thiourea and 2.5g of dicyandiamide into a mortar and grind thoroughly to obtain a homogeneous mixture, place the mixture in a muffle furnace at 500°C for 1h, then heat up to 550°C for 2h, and cool naturally To room temperature, after grinding, obtain graphene-like carbon nitride (g-C 3 N 4 ).

[0042] (2) Add 0.02gWS with a mass ratio of 4.0% to 25mL hydrochloric acid ethanol solution (hydrochloric acid volume fraction is 12%) 2 (average particle size is 6μm) and 0.05gg-C 3 N 4 , sonicated for 20 min to obtain a dispersion. Transfer the dispersion liquid to a 25mL hydrothermal reaction kettle, and hydrothermally treat it in an oven at 80°C for 10 hours. get WS 2 / g -C 3 N 4 Complex.

[0043] (3) Prepare 16mL of 0.4mol / L TiCl 4 Ethanol solution in a 100mL beaker, according to WS 2 / g -C 3 N 4 :TiO 2 =9wt% Add 0.058g of WS to the ethanol solution 2 / g -C 3 N 4 The composite was ultrasonicated for 60 min at room temperature to obtain a mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com