A preparation method of activated carbon-supported catalyst for electrocatalytic degradation of organic wastewater

A supported catalyst, electrocatalytic degradation technology, applied in physical/chemical process catalysts, chemical instruments and methods, water pollutants, etc., can solve the problems of high production equipment requirements, complex preparation process, limited adsorption capacity, etc. The effect of uniformity and refinement, increase of specific surface area, and improvement of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

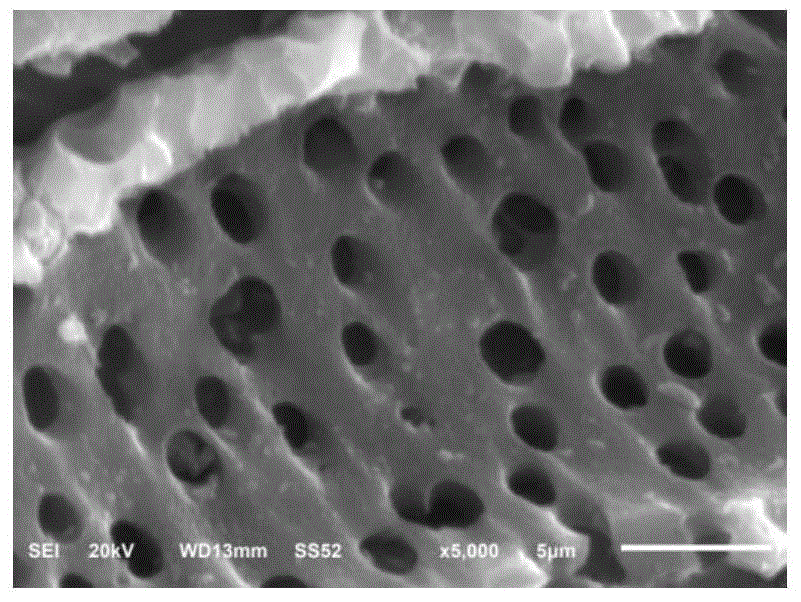

[0046] A preparation method of an activated carbon-supported catalyst for electrocatalytic degradation of organic wastewater according to the present embodiment, the method comprises the following steps:

[0047] (1) the particle diameter is that 30 mesh gacs are soaked in 40% nitric acid aqueous solution for 24h with a mass concentration, and after filtering, the filter cake is washed with deionized water until the pH value of the washing liquid is detected to be 7, and then the filter cake is soaked at 100 ℃ in a drying oven to obtain pretreated activated carbon for subsequent use;

[0048] (2) Get 20g of activated carbon after the pretreatment described in step (1), 2.256g (40ml 0.3M) Cu(NO 3 ) 2 , 0.131g (20ml 0.02M) Ce (N0 3 ) 3 Mix with 2.304g (40ml 0.3M) citric acid, make mixed reaction solution after stirring evenly, then in described mixed reaction solution, dropwise add ammoniacal liquor, the pH value of adjustment reaction solution is 6.5, then in 80 ℃ of water b...

Embodiment 2

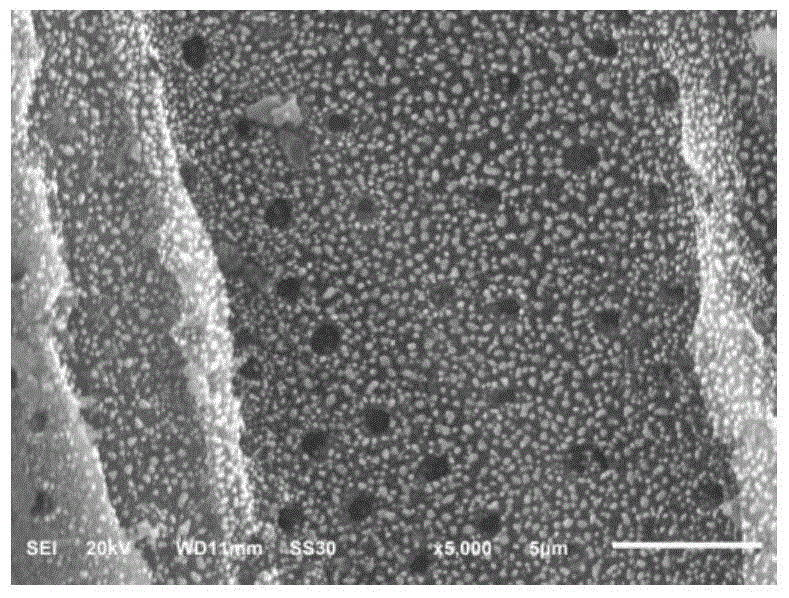

[0057] A preparation method of an activated carbon-supported catalyst for electrocatalytic degradation of organic wastewater according to the present embodiment, the method comprises the following steps:

[0058] (1) Be that 15 mesh gacs are soaked in 40% nitric acid aqueous solution for 24h with the particle size, after filtering, the filter cake is washed with deionized water until the pH value of the washing liquid is detected to be 7, and then the filter cake is soaked at 100 ℃ in a drying oven to obtain pretreated activated carbon for subsequent use;

[0059] (2) Get 20g of activated carbon after the pretreatment described in step (1), 1.121g (20ml 0.25M) Fe(NO 3 ) 3 , 0.1g (20ml 0.015M) (Ce(N0 3 ) 3 Mix with 1.152g (20ml 0.3M) citric acid, make mixed reaction solution after stirring evenly, then dropwise add ammoniacal liquor in the described mixed reaction solution, adjust the pH value of reaction solution to be 8.0, then in 80 ℃ of water bath conditions Under the r...

Embodiment 3

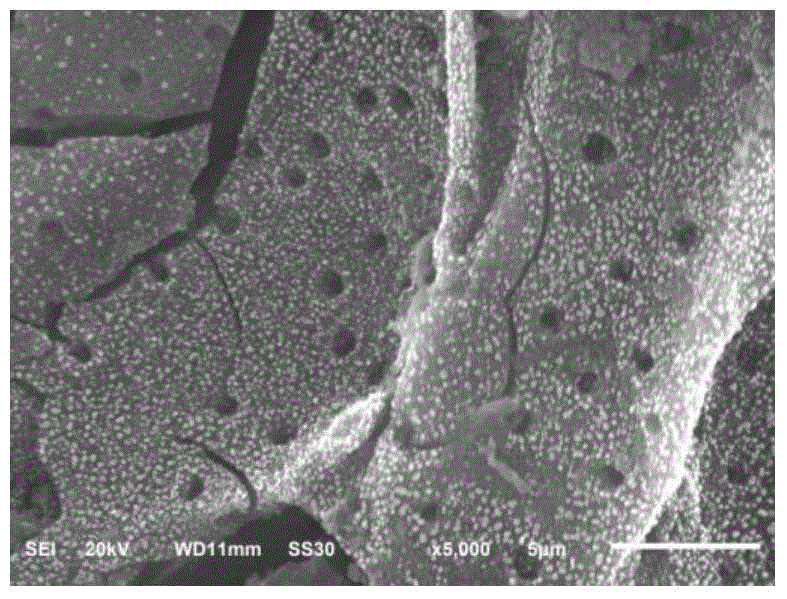

[0066] A preparation method of an activated carbon-supported catalyst for electrocatalytic degradation of organic wastewater according to the present embodiment, the method comprises the following steps:

[0067] (1) the particle diameter is that 30 mesh gacs are soaked in 40% nitric acid aqueous solution for 24h with a mass concentration, and after filtering, the filter cake is washed with deionized water until the pH value of the washing liquid is detected to be 7, and then the filter cake is soaked at 100 ℃ in a drying oven to obtain pretreated activated carbon for subsequent use;

[0068] (2) Get 20g of activated carbon after pretreatment in step (1), 0.94g (20ml 0.25M) Cu(NO 3 ) 2 , 1.452g (30ml 0.2M) Fe(NO 3 ) 3 , 0.326g (20ml 0.05M) Ce (N0 3 ) 3 Mix with 3.84g (40ml 0.5M) citric acid, make mixed reaction solution after stirring evenly, then in described mixed reaction solution, dropwise add ammoniacal liquor, the pH value of adjustment reaction solution is 8.5, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com