Distillation and water purifying equipment adopting solar

A technology of water purification equipment and solar energy, applied in the direction of solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problems of large flow heat loss, easy fouling of distillation tanks, and inability to improve the absorption rate of solar radiation, etc., to achieve transmission The effect of small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

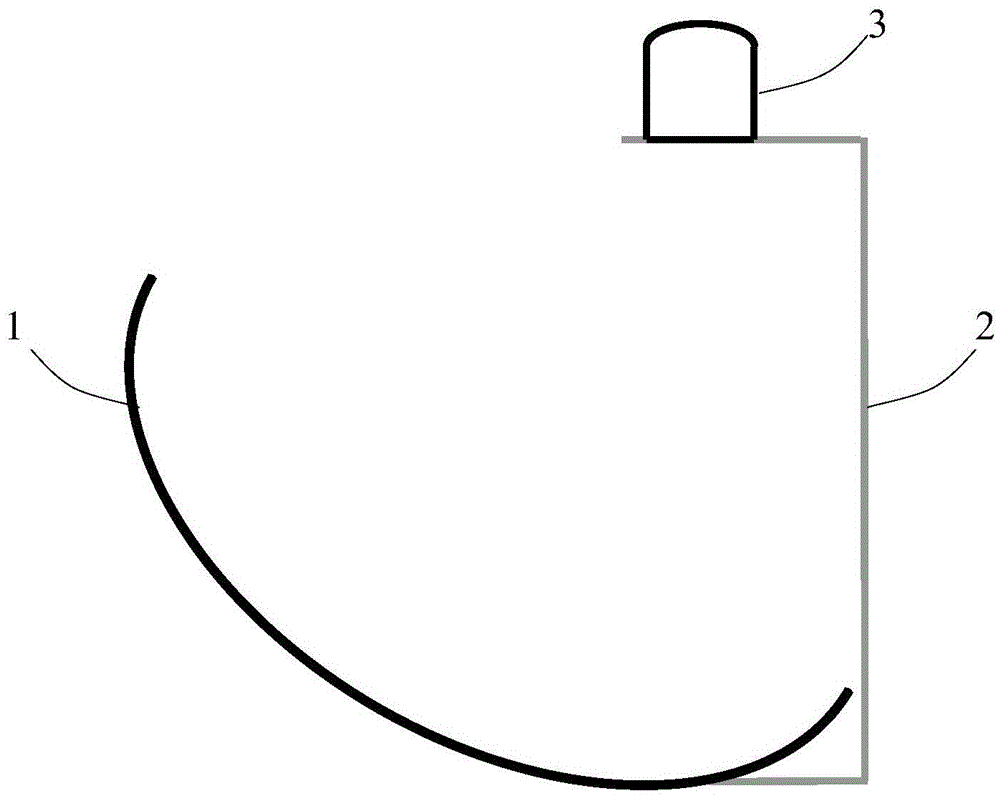

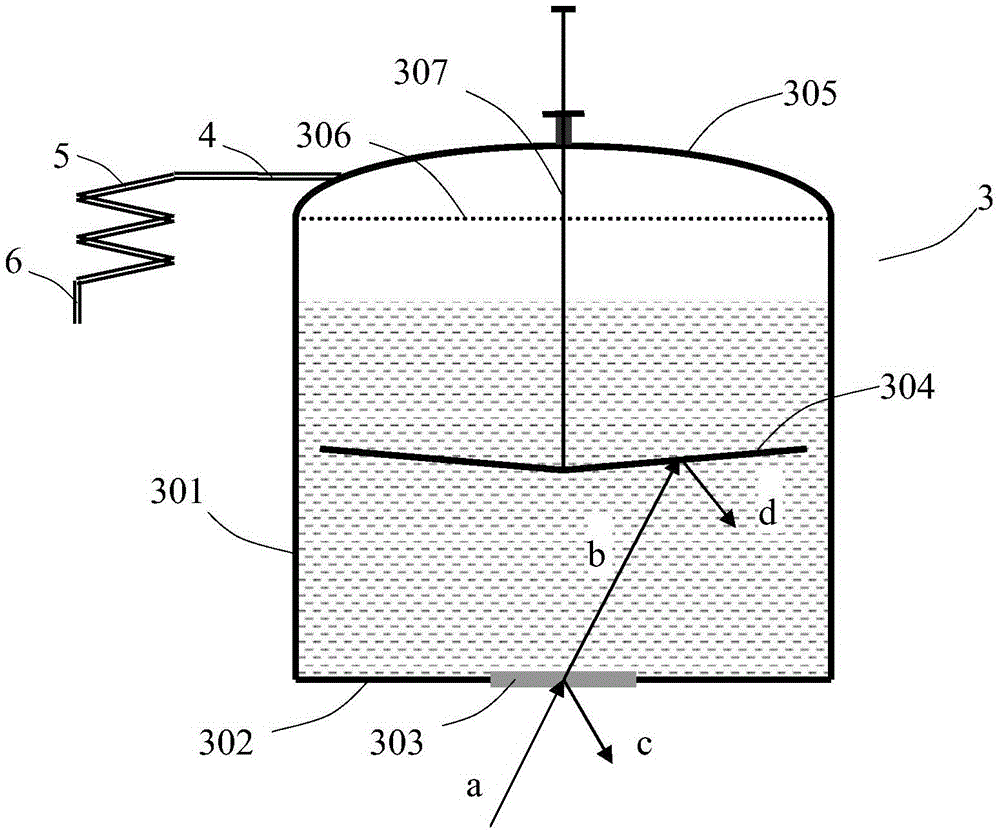

[0044] Solar energy distilled water purifying equipment of the present invention, as figure 1 As shown, the concentrator 1 focuses the reflection of sunlight to the retort 3 placed on the support 2 . see figure 2 , the retort 3 is a cylindrical container (its outer surface and inner surface are black), including a cylindrical side wall 301, and a plate glass window 303 is provided at the center of the bottom 302. Inside the distillation tank 3, there is a heat absorbing plate 304 located below the liquid surface and a defoaming plate 306 above the liquid surface. The defoaming plate 306 is fixedly installed in the upper cover 305, and there are many small holes distributed on the defoaming plate 306. , when the water in the distillation tank 3 is heated and boiled, the foam removal plate 306 can remove the foam droplets in the water vapor. The middle part of defoaming plate 306 has garden hole to let pull rod 307 pass through, and pull rod 307 lower end is connected black h...

Embodiment 2

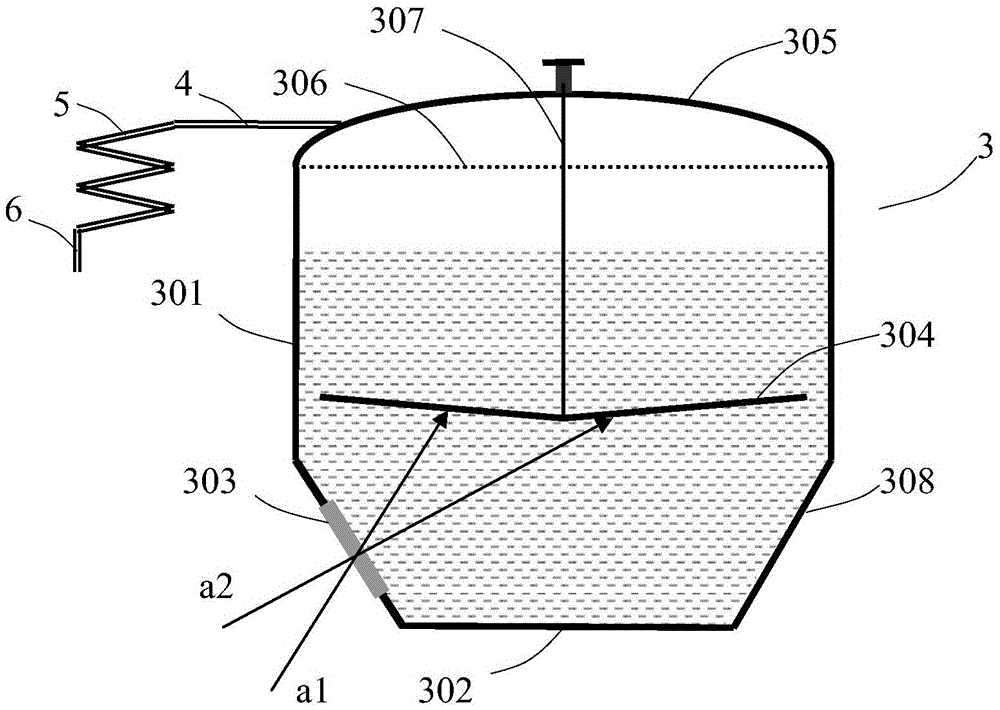

[0068] This embodiment is similar to Embodiment 1, the difference is that the plate glass window of this embodiment is arranged on the inclined wall of the retort. Specifically as image 3 As shown, the lower part of the cylindrical side wall 301 of the retort 3 has a conical transition section 308 on which the plate glass window 303 is located. This arrangement is conducive to the incidence of sun spots from various angles. For example, image 3 Both the sunlight with an incident angle of about 60° (arrow a1) and the sunlight with an angle of 30° (arrow a2) can achieve better incidence and be fully absorbed by the heat-absorbing plate and the inner wall.

[0069] Other similar arrangements include: disposing protrusions or recesses on the wall of the retort 3, these protrusions or recesses have a wall or transition section with an angle of 30° to 60° with the horizontal plane, flat glass The windows 303 are arranged on these wall surfaces or transition sections with an inc...

Embodiment 3

[0072] This embodiment is similar to Embodiment 1, the difference is that this embodiment uses concave glass windows. Specifically as Figure 4 As shown, the bottom 302 of the retort 3 is provided with a concave glass window 309 made of a glass cylinder, and the solar light transmittance of the glass cylinder material is, for example, 90%. After the solar radiation enters the opening of the glass cylinder from the direction of the arrow a, 90% of the solar radiation passes through the wall of the glass cylinder and reaches the lower surface of the heat-absorbing plate 304 along the direction of the arrow b, and the other 10% is reflected by the wall of the glass cylinder. The direction of the arrow c reaches the bottom of the glass cylinder; then, most of the solar radiation of the b arrow is converted into heat energy on the lower surface of the heat absorbing plate 304 to heat the water, and the remaining small amount is reflected by the heat absorbing plate 304 and reaches ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com