Polyimide film and preparation method thereof

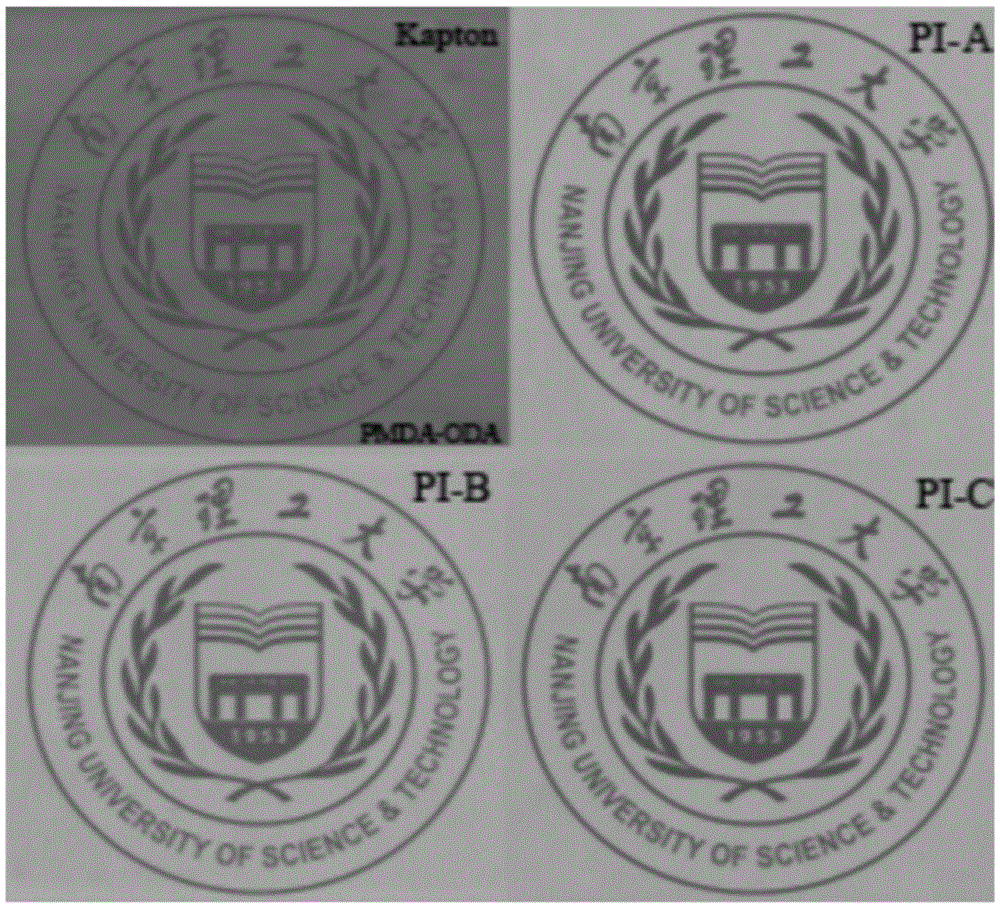

A polyimide film and film release technology, applied in the field of polymer materials, can solve the problems of mechanical and thermal properties, inability to have transparency and adhesion at the same time, and achieve good processing performance and excellent colorless transparency , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040](1) Add 9.2874g of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl and 70mL of N,N-dimethyl Acetamide (DMAC), stirred at 20-25°C for half an hour until completely dissolved, added 0.4216mL of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, Continue to stir for half an hour until the two diamines are evenly dispersed. The temperature of the system was lowered to 15°C, 4.6110g of 4,4-hexafluoroisopropylphthalic anhydride and 10mL of DMAC were added, and the reaction was continued for 1h. The temperature of the system was lowered to 8°C, and 4.6110g of 4,4-hexafluoroisopropylphthalic anhydride and 10mL of DMAC were added continuously, and the reaction was continued for 1h. Maintain the temperature of the system at 8°C, add the remaining 4.6110g of 4,4-hexafluoroisopropylphthalic anhydride and 10mL of DMAC, and continue the reaction for 15h to obtain a homogeneous, transparent, and viscous polyamic acid solution. The viscosity is 1526.3cp.

[0041] (2) Filter and defoa...

Embodiment 2

[0043] (1) Add 4.4199g of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl and 35mL of DMAC to a four-necked flask with nitrogen gas, a thermometer and a stirrer. Stir for half an hour until completely dissolved, add 0.4234mL of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, continue stirring for half an hour until the two diamines are evenly dispersed . The temperature of the system was lowered to 15°C, 2.3163g of 4,4-hexafluoroisopropylphthalic anhydride and 5mL of DMAC were added, and the reaction was continued for 1h. The temperature of the system was lowered to 8°C, and 2.3163g of 4,4-hexafluoroisopropylphthalic anhydride and 5mL of DMAC were added continuously, and the reaction was continued for 1h. Maintain the system temperature at 8°C, add the remaining 2.3163g of 4,4-hexafluoroisopropylphthalic anhydride and 5mL of DMAC, and continue the reaction for 20h to obtain a homogeneous, transparent, and viscous polyamic acid solution. The viscosity is 1419.0.3cp.

[00...

Embodiment 3

[0046] Add 7.9318g of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl and 70mL of DMAC to a four-necked flask with nitrogen gas, a thermometer and a stirrer, and stir at 20-25°C for half After 1 hour until completely dissolved, add 1.7098mL of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, and continue to stir for half an hour until the two diamines are evenly dispersed. Lower the temperature of the system to 15°C, add 7.0147g of 4,4-hexafluoroisopropylphthalic anhydride and 5mL of DMAC, and continue the reaction for 1h; lower the temperature of the system to 8°C, and continue to add 3.5074g of 4,4-hexafluoroisopropyl 1.7537g of 4,4-hexafluoroisopropylphthalic anhydride and 5mL of DMAC were added to maintain the system temperature at 8°C; and 0.8768g4 was added to maintain the reaction temperature at 8°C. 4-Hexafluoroisopropylphthalic anhydride and 5mL DMAC, continue to react for 1h; maintain the reaction temperature at 8°C, add the remaining 0.8768g of 4,4-hexafluoroisopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com