A kind of insulation-coated anti-corrosion alloy bonding wire and preparation method thereof

An alloy bonding and insulating coating technology, which is applied to insulated conductors, insulated cables, metal/alloy conductors, etc., can solve the problems of low production efficiency and uneven film coating, and achieve high production efficiency, low cost, and increased production. Effect of Bonding Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

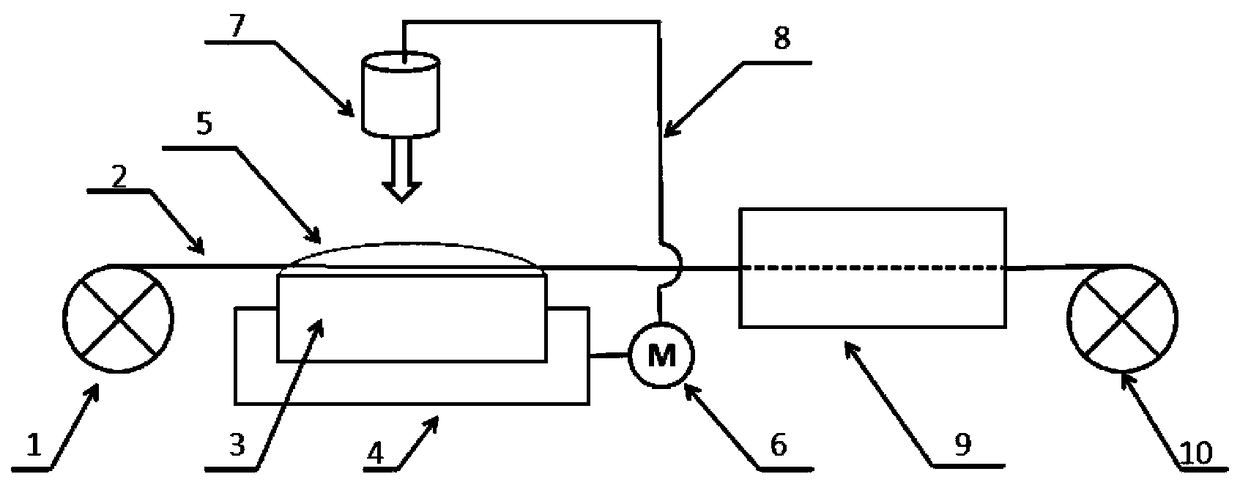

Method used

Image

Examples

Embodiment 1

[0034] Example 1: An insulating coated corrosion-resistant silver alloy bonding wire with a diameter of 25 μm (1.0 mil, not including the thickness of the insulating coating), the weight percentage of each component of the material constituting the bonding wire is:

[0035] The amount of Au (gold) is 9%, the amount of Pd (palladium) is 3%, the amount of Ce (cerium) is 5ppm, and the balance is Ag as the alloy substrate; the material of the outer insulating film is thermoplastic biphenyl polyimide resin.

[0036] Its preparation method comprises the following steps:

[0037] The first step is to select the alloy substrate: select silver metal raw materials with a high purity of more than 99.999%;

[0038] The second step, melting and casting: according to the percentage of alloy composition, use N at 1600°C 2 Blowing and stirring protection for pre-alloying and master alloying, continuous drawing casting process at 1250°C, melting and casting into silver alloy metal rods with ...

Embodiment 2

[0044] Example 2: A bonding wire with a diameter of 30 μm (1.2 mil, not including the thickness of the insulating coating) with an insulating coating and an anti-corrosion copper alloy. The weight percentages of the components of the bonding wire are:

[0045] The amount of Ag (silver) is 0.5%, and the balance is Cu (copper) as the alloy substrate; the material of the outer insulating film is thermoplastic polyphenylene polyimide resin.

[0046] Its preparation method comprises the following steps:

[0047] The first step is to select the alloy base material: select copper metal raw materials with a high purity of more than 99.999%;

[0048] The second step, melting and casting: according to the percentage of alloy composition, use N at 1300°C 2 Blowing and stirring protection for pre-alloying and master alloying, continuous drawing casting process at 1250°C, melting and casting into copper alloy metal rods with a diameter of 8±0.3mm;

[0049] The third step, wire drawing: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com