Formula food with special medical application and preparation method thereof

A medical food and application technology, applied in the field of biochemistry, can solve the problems of difficulty in the industrial production of milk-derived bioactive peptides, low initial whey protein concentration, and low yield of active peptides, and reduce the possibility of human immune rejection Sexuality, easy absorption by the body, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

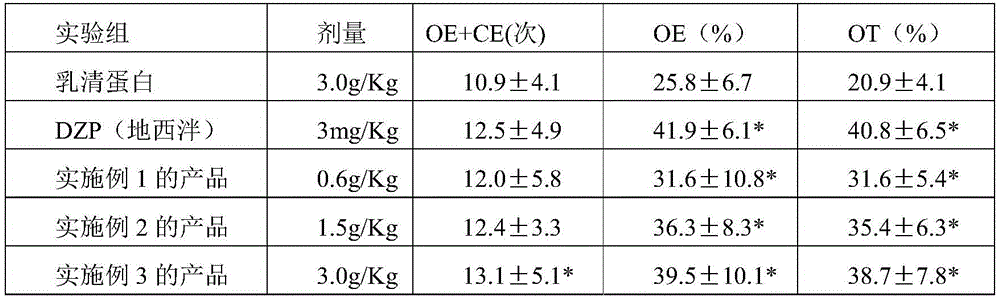

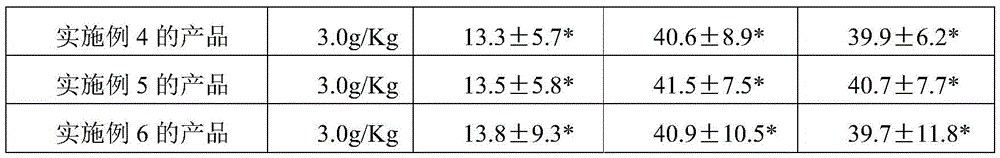

Embodiment 1

[0046] Weigh 50g of whey protein, hydrate it, and prepare it into a whey protein suspension of 1.0wt%, and add folic acid and five thousandths of the whey protein amount to the whey protein suspension. For niacin, add trypsin and papain (composed according to the weight ratio of 2:1) with a mass of 0.1% of the whey protein amount to the whey protein suspension. Under constant temperature conditions of 45°C, a completely transparent solution was obtained after enzymatic hydrolysis in a constant temperature enzymatic hydrolysis tank for 1 hour. After testing, the degree of hydrolysis of whey protein was 36.5%, and then the whey protease hydrolyzate in the reaction system was heated rapidly to 100° C. and kept for 20 minutes to inactivate the enzyme. The degree of hydrolysis is controlled, and then the obtained whey protein peptide solution is concentrated, spray-dried, and the inlet air temperature is controlled at 190°C, the outlet air temperature is 95°C, and the feed flow rat...

Embodiment 2

[0048] Weigh 50g of whey protein, hydrate it, and prepare 5.0wt% whey protein suspension, add folic acid and 3 / 1000th of the whey protein amount to the whey protein suspension Niacin, add 0.2% of whey protein Bioprase SP-20 and papain (composed of according to the weight ratio of 3:1) to the whey protein suspension, under 40 ℃ of constant temperature conditions, in the constant temperature enzymolysis tank After hydrolysis for 6 hours, a completely transparent solution was obtained. After testing, the degree of hydrolysis of whey protein is 41.2%, and then the reaction system whey protease hydrolyzate is rapidly heated to 100°C and kept for 20 minutes to inactivate the enzyme and control the degree of hydrolysis, and then concentrate the obtained whey protein peptide solution , Spray drying, controlling the inlet air temperature to 190°C, the outlet air temperature to 95°C, and the feed flow rate to 20ml / min to obtain powdered compound whey protein peptide products. After tes...

Embodiment 3

[0050] Weigh 50g of whey protein, hydrate, and prepare 20.0wt% whey protein suspension, add folic acid and 1 / 1000th of the whey protein amount of folic acid and 1 / 1000th of the whey protein suspension acid, add Bioprase SP-20 with 0.5% whey protein amount and papain (composed of according to the weight ratio of 1:1) to the whey protein suspension, under the constant temperature condition of 50 ℃, enzymatic hydrolysis in the constant temperature enzymolysis tank for 8h A completely transparent solution was obtained. After testing, the degree of hydrolysis of whey protein is 47.3%, and then the reaction system whey protease hydrolyzate solution is rapidly heated to 100°C and kept for 20 minutes to inactivate the enzyme and control the degree of hydrolysis, and then concentrate the obtained whey protein peptide solution , Spray drying, controlling the inlet air temperature to 190°C, the outlet air temperature to 95°C, and the feed flow rate to 10ml / min to obtain a powdered comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com