Tissue engineering meniscus scaffold and preparation method thereof

A tissue engineering, meniscus technology, applied in the direction of tissue regeneration, additive processing, medical science, etc., can solve problems such as the inability to meet the performance requirements of the meniscus stent, and achieve improved tensile and compressive elastic modulus, good mechanical properties, The effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

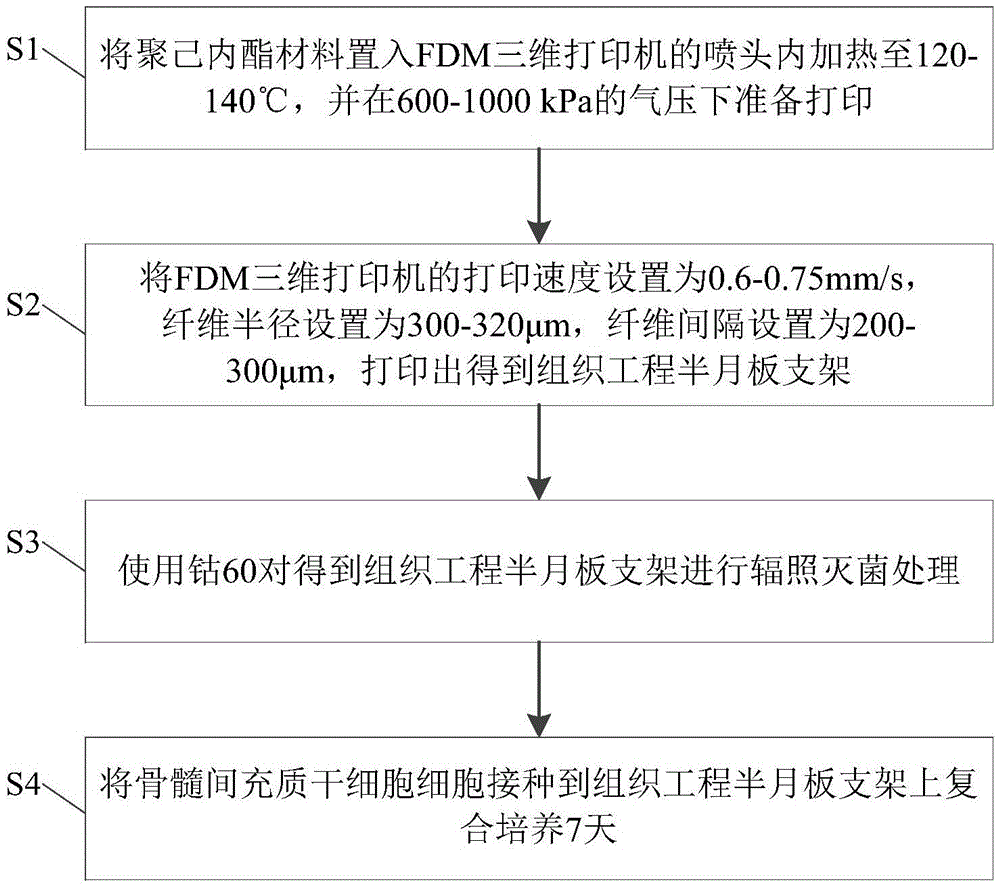

[0030] see figure 1 , is a flowchart of a method for preparing a tissue engineered meniscus scaffold according to a preferred embodiment of the present invention. Such as figure 1 As shown, the preparation method provided by this embodiment mainly includes the following steps:

[0031] First, in step S1, put the polycaprolactone (PCL) material into the nozzle of the fused deposition modeling (FDM) three-dimensional printer, heat it to 120-140°C, and prepare for printing under the pressure of 600-1000kPa. The fused deposition modeling 3D printer includes a high-precision pneumatic 3D experimental platform and a sharp pen direct writing nozzle. Preferably, the weight average molecular weight Mw of the PCL material is 60000, and the melting point is 60°C.

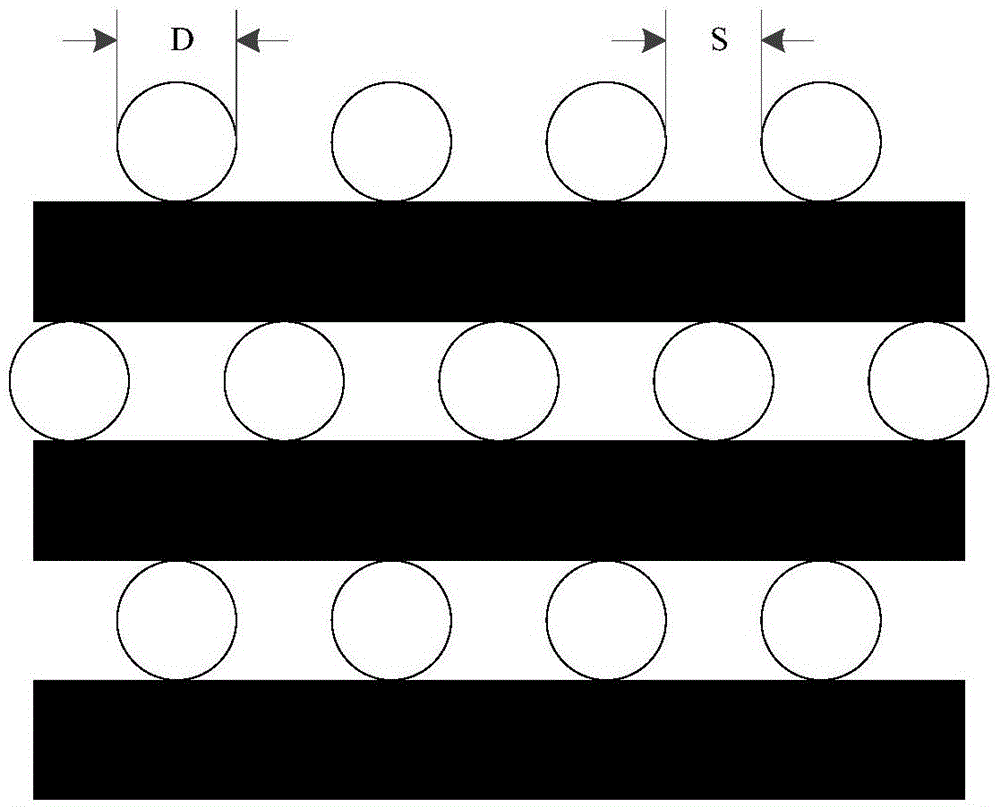

[0032] Subsequently, in step S2, the printing speed of the FDM three-dimensional printer is set to 0.6-0.75 mm / s, the fiber diameter is set to 300-320 μm, and the fiber spacing is set to 200-300 μm, and the tissue engineeri...

Embodiment 1

[0040] 1. Put the polycaprolactone material into the nozzle of the fused deposition modeling 3D printer, heat it to 120-140°C, and prepare for printing under the pressure of 600-1000kPa.

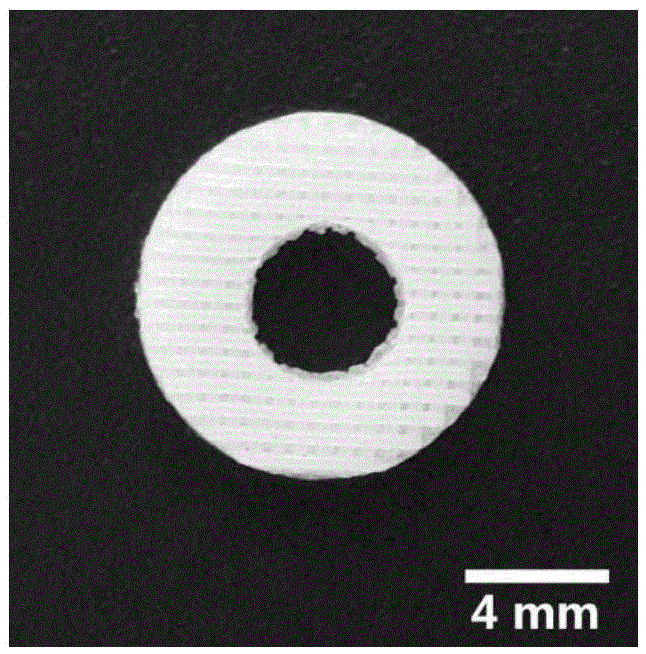

[0041] 2. Set the printing speed of the fused deposition modeling 3D printer to 0.6-0.75 mm / s, the fiber diameter to 300 μm, and the fiber spacing to 200 μm to print out a ring-shaped tissue engineering meniscus scaffold, in which the ring outer diameter d1 is 10 mm. The inner diameter d2 of the ring is 4 mm, and the thickness h is 1.5 mm.

[0042] 3. Using cobalt-60 to sterilize the tissue engineered meniscus bracket by irradiation.

Embodiment 2

[0044] 1. Put the polycaprolactone material into the nozzle of the fused deposition modeling 3D printer, heat it to 120-140°C, and prepare for printing under the pressure of 600-1000kPa.

[0045] 2. Set the printing speed of the fused deposition modeling 3D printer to 0.6-0.75 mm / s, the fiber diameter to 320 μm, and the fiber spacing to 300 μm to print out a ring-shaped tissue engineering meniscus scaffold, in which the ring outer diameter d1 is 10.5 mm , the ring inner diameter d2 is 4.5mm, and the thickness h is 1.6mm.

[0046] 3. Using cobalt-60 to sterilize the tissue engineered meniscus bracket by irradiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com