Modified biological filter packing

A biological filter and modification technology, applied in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of poor hydrophilic performance and biological affinity, low pollution load, slow growth rate, etc. , to achieve the effects of strong hydrophilicity and bioaffinity, improved transformation speed and efficiency, large proliferation and metabolic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

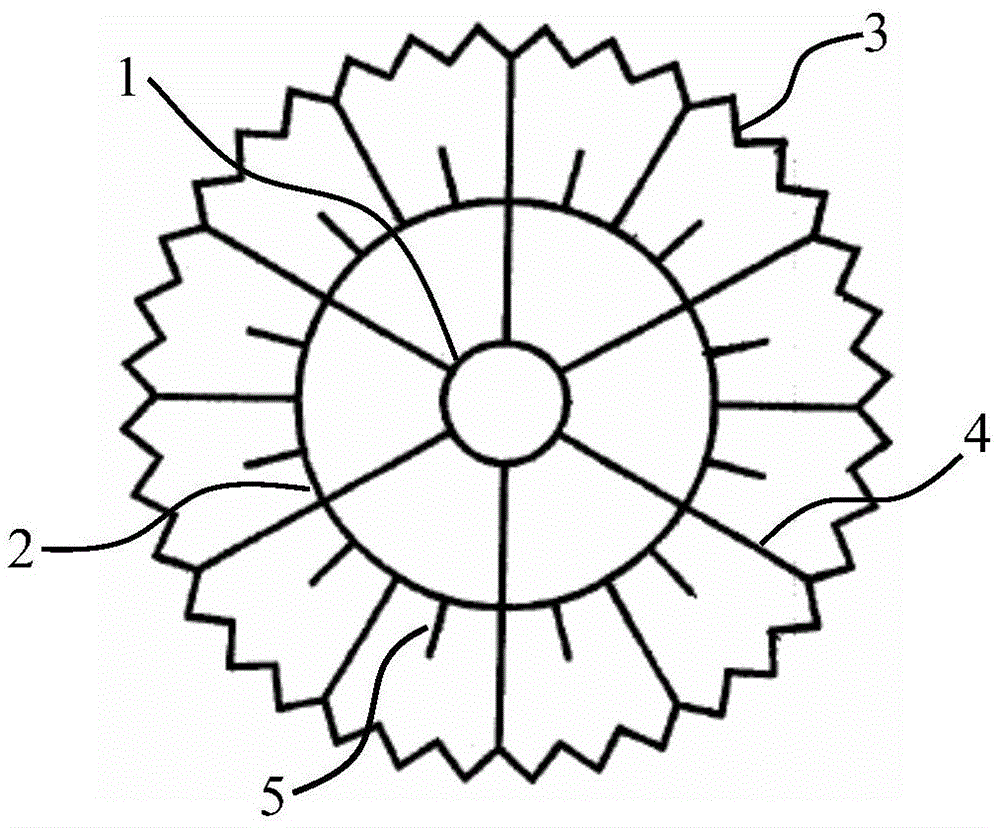

[0032] Embodiments 1 to 4: A modified biofilter filler, which includes a short hollow tube 1, a first concentric ring 2 concentrically arranged outside the short hollow tube 1, and a second concentric ring 2. Ring 3, the hollow short tube 1, the first concentric ring 2 and the second concentric ring 3 are connected by ribs 4, and the surface of the outermost second concentric ring 3 is serrated;

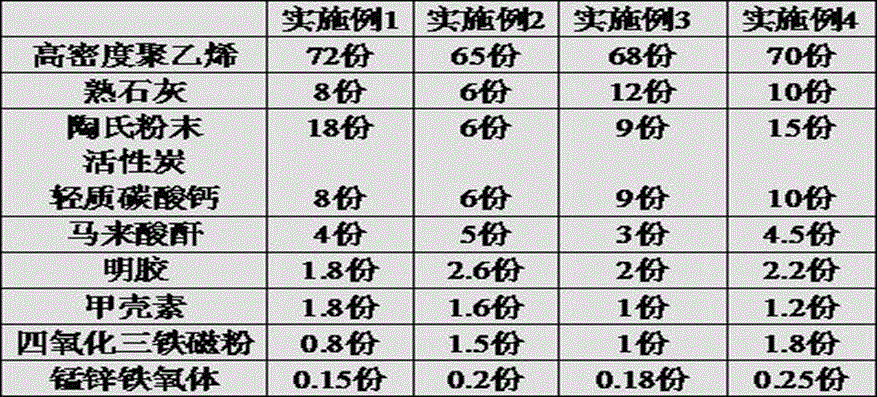

[0033] The suspended microbial filler is composed of the following components by weight, as shown in Table 1:

[0034] Table 1

[0035]

[0036] The density of the above-mentioned modified biofilter filler is 0.96~0.98g / cm 3 .

[0037] The above-mentioned slaked lime is mixed with Dow powdered activated carbon and light calcium carbonate according to the ratio of 1:1.2:0.9 by weight.

[0038] A manufacturing method for the above-mentioned modified biofilter filler, comprising the following steps:

[0039] Step 1, take 3 to 5 parts of maleic anhydride, dissolve them with 2.5 kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com