Comprehensive utilization method of nickel and iron slags

A technology for nickel-iron slag and filter slag, which is applied to the treatment field of ferroalloy slag, can solve the problems of swelling of building materials, high content of silicon and magnesium, and low content of calcium, and achieves the effect of reducing the stock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

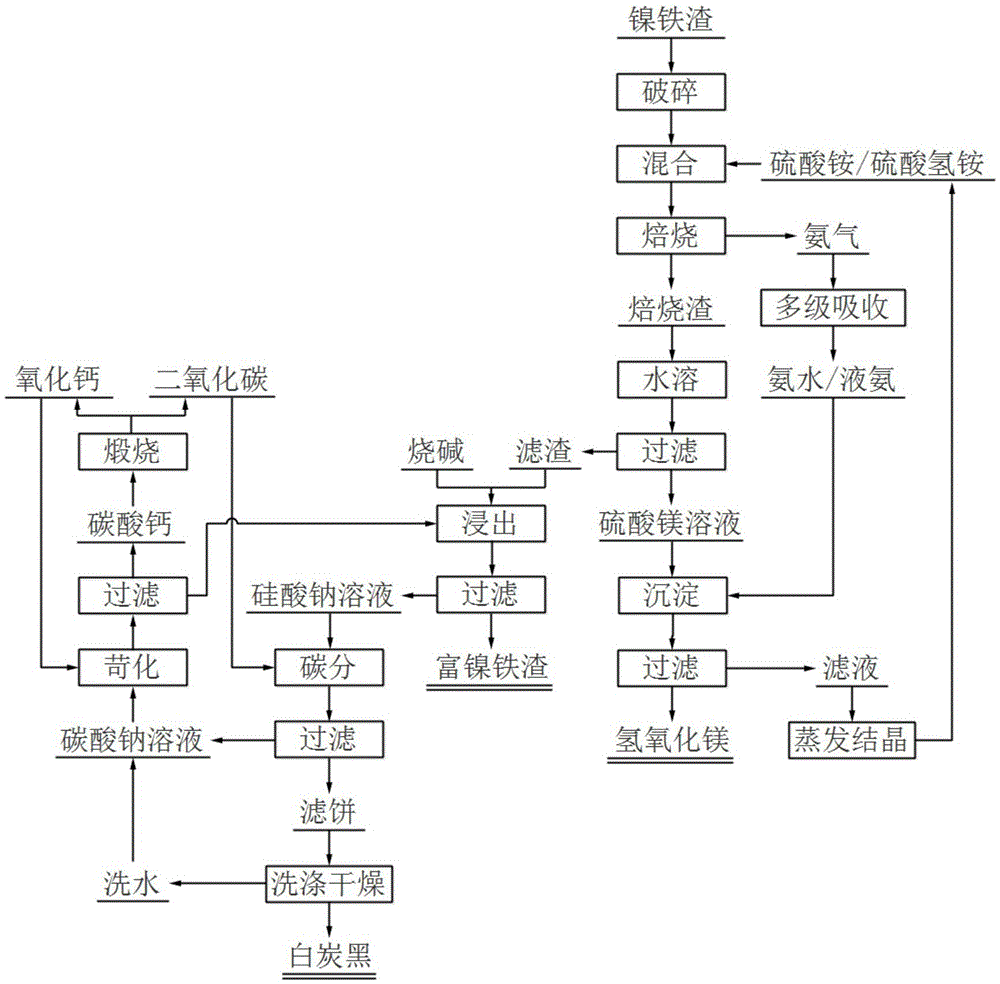

[0015] Such as figure 1 As shown, a comprehensive utilization method of nickel-iron slag, the method steps are as follows:

[0016] 1. Inspect the chemical composition of nickel-iron slag, the result is: NiO0.16%, SiO 2 53.48%, Fe 2 O 3 5.91%, CaO1.56%, MgO28.34%, Al 2 O 3 4.62%, other 5.93%;

[0017] 2. After the ferronickel slag is crushed and finely ground to below 100 mesh, it is mixed with ammonium sulfate according to the mass ratio of ammonium ore 4:1, and roasted at 400°C for 2 hours. The ammonia generated during the roasting process is absorbed by water and used for roasting After 3 times the volume of water is fully dissolved, liquid-solid separation is performed to obtain magnesium sulfate filtrate and filter residue;

[0018] 3. Continuously add ammonia water to the magnesium sulfate filtrate, keep the solution temperature at 60°C, control the pH value to 9, fully stir until no precipitation occurs, filter the solution after the precipitation, to obtain the magnesium hyd...

Embodiment 2

[0022] Such as figure 1 As shown, a comprehensive utilization method of nickel-iron slag, the method steps are as follows:

[0023] 1. Check the chemical composition of nickel-iron slag, the result is: NiO0.22%, SiO 2 51.78%, Fe 2 O 3 7.06%, CaO3.39%, MgO29.17%, Al 2 O 3 2.86%, other 5.52%;

[0024] 2. After the ferronickel slag is crushed and finely ground to below 150 mesh, it is mixed with ammonium bisulfate at a mass ratio of 5:1 and roasted at 450°C for 1.5 hours. The ammonia produced during the roasting process is pressurized and liquefied to obtain a liquid Ammonia and roasting residue are fully dissolved in 4 times the volume of water and then liquid-solid separation is performed to obtain magnesium sulfate filtrate and filter residue;

[0025] 3. Continuously add liquid ammonia to the magnesium sulfate filtrate, keep the temperature of the solution at 50°C, control the pH value to 10, and stir well until no more precipitation occurs. The solution after precipitation is fil...

Embodiment 3

[0029] Such as figure 1 As shown, a comprehensive utilization method of nickel-iron slag, the method steps are as follows:

[0030] 1. Inspect the chemical composition of nickel-iron slag, the result is: NiO 0.37%, SiO 2 49.65%, Fe 2 O 3 8.33%, CaO4.75%, MgO30.62%, Al 2 O 3 3.18%, other 3.1%;

[0031] 2. After the ferronickel slag is crushed and finely ground to below 120 mesh, it is mixed with the mixture of ammonium sulfate and ammonium bisulfate according to the ammonium ore mass ratio 4:1, and roasted at 460℃ for 2 hours. The ammonia gas produced during the roasting process is water The ammonia water is obtained by absorption, the roasting residue is fully dissolved in 5 times the volume of water, and then liquid-solid separation is performed to obtain magnesium sulfate filtrate and filter residue;

[0032] 3. Continuously add liquid ammonia to the magnesium sulfate filtrate, keep the temperature of the solution at 55°C, control the pH value to 10, and stir well until no more pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com