Method for preparing graphite-titanium oxide composite

A technology of titanium oxide and manufacturing method, applied in the directions of titanium oxide/hydroxide, chemical instruments and methods, graphite, etc., can solve the problems of high irreversible capacity and low thermal stability, achieve common use, delay graphite Structural collapse, improved effect of rate-determining properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] graphite-lithium titanium oxide (Li 4 Ti 5 o 12 ) complexes

[0090] Firstly, the graphite is dispersed by benzyl alcohol and then filtered to obtain the surface-modified graphite. Next, it is put into ethanol and distilled water for uniform dispersion, and then the titanium precursor is put into it for stirring and hydrolysis, and after a uniform coating is formed on the graphite surface, it is filtered and dried.

[0091] Next, the graphite-titanium oxide powder and lithium hydroxide aqueous solution produced above were put into a polytetrafluoroethylene container, and a hydrothermal synthesis treatment was performed at 80° C. for 10 hours.

[0092] In an argon (Ar) environment at 600°C, the mixture produced by hydrothermal synthesis was heat-treated for 2 hours to complete graphite-lithium titanium oxide (Li 4 Ti 5 o 12 )Complex.

Embodiment 2

[0093] graphite-titanium oxide (TiO 2 ) complexes

[0094] In the graphite-lithium titanium oxide (Li 4 Ti 5 o 12 ) complex, the stage of adding lithium precursors for hydrothermal synthesis is not performed, and graphite-titanium oxide (TiO 2 ).

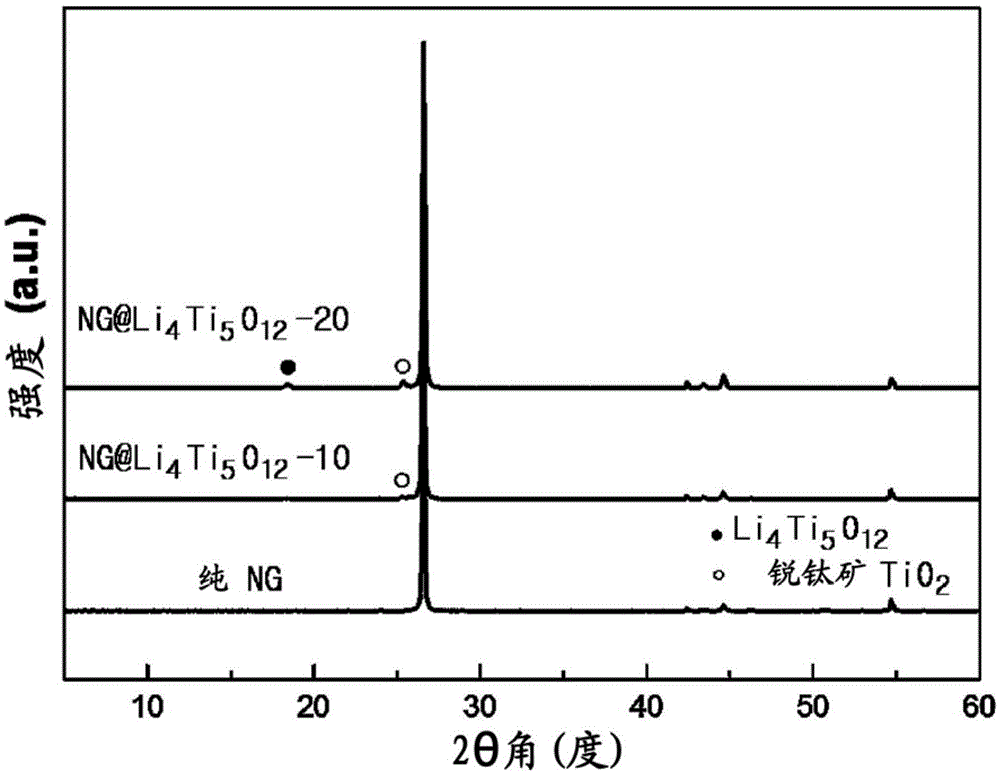

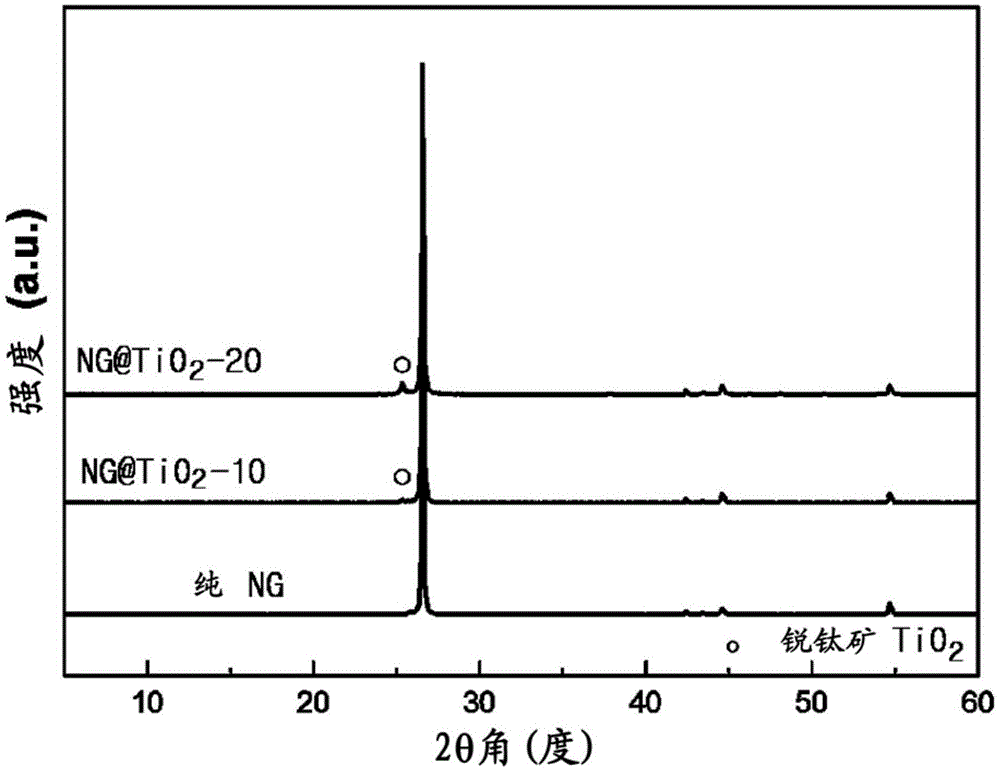

[0095] X-ray refraction analysis

[0096] In order to analyze the structure of the graphite-(lithium) titanium oxide composite produced in the above-mentioned Examples 1 and 2, X-ray refraction analysis was carried out with graphite particles as a control group. The results are as follows figure 1 , 2 shown.

[0097] Such as figure 1 , 2 As shown, graphite exhibits a characteristic peak (peak), and the graphite-(lithium) titanium oxide composite produced by the present invention also exhibits a characteristic peak at the same 2θ angle as graphite. In addition, as the ratio of titanium precursor to graphite increases, the corresponding Li 4 Ti 5 o 12 , TiO 2 Peak.

[0098] From the above results, it was confirmed tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com