A nitrogen-doped ordered porous highly conductive graphene fiber and its preparation method and application

A technology of graphene fiber and nitrogen doping, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, etc. It can solve the problems of electrochemical performance improvement and limited space for improvement, poor electrochemical performance, and no simultaneous realization. , to achieve the effect of facilitating electron transmission, increasing the total capacitance, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

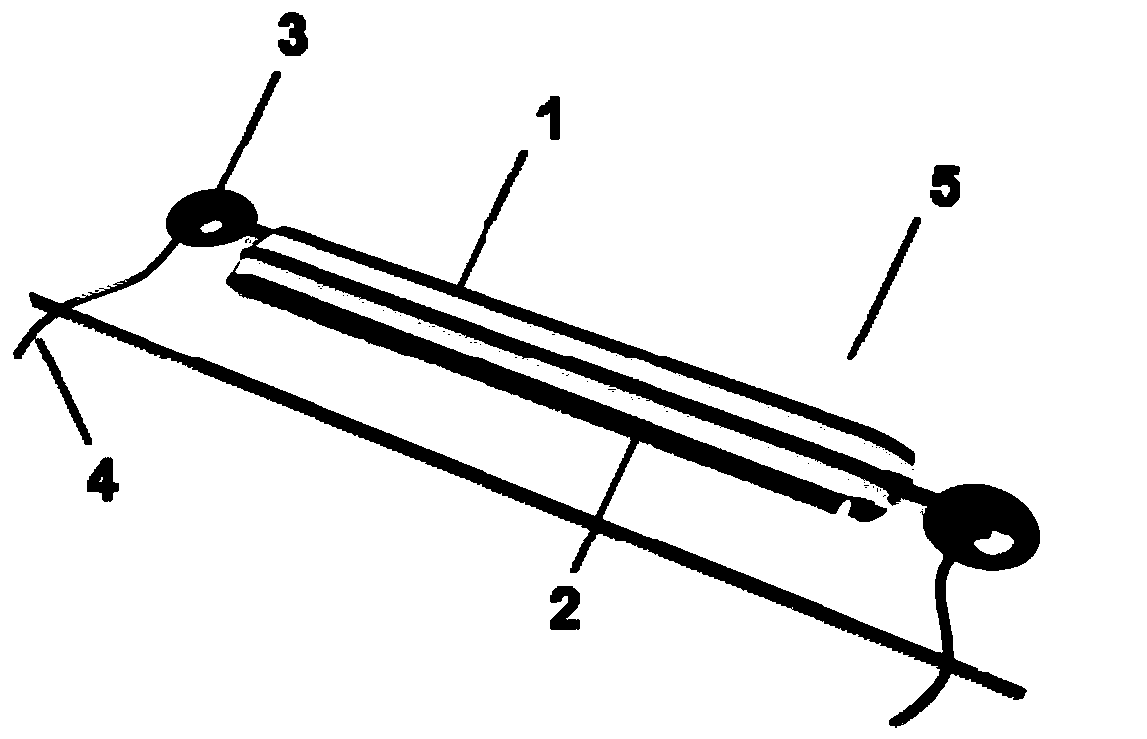

[0049] Using 160-mesh natural graphite flakes as raw materials, the graphene oxide aqueous solution was prepared according to the Hummers improved method, and after centrifugation and concentration at a speed of 12,000 rpm or more for 50 minutes, a 14 mg / mL graphene oxide dispersion was obtained; 30 mL of the graphene oxide was dispersed solution and 210 mg urea (mass ratio of graphene oxide to urea is 1:0.5) were fully stirred and mixed evenly, and the above mixed solution was injected into a polytetrafluoroethylene cylinder with an inner diameter of 3 mm through a needle at an extrusion speed of 20 mL / h. Shaped microchannel and sealed at both ends, placed in an oven and heated at 90°C for 4h, then hydrothermally reacted at 160°C for 5h to obtain amino-functionalized graphene fibers; then cooled the cylindrical microchannel to room temperature Open the seals at both ends and dry at 90°C to obtain dehydrated amino-functionalized graphene fibers; the dried amino-functionalized g...

Embodiment 2

[0056] Using 100-mesh natural graphite flakes as raw materials, the graphene oxide aqueous solution was prepared according to Hummers' improved method, and after centrifugation and concentration at a speed of more than 13,000 rpm for 60 minutes, a 20 mg / mL graphene oxide dispersion was obtained; 30 mL of the graphene oxide dispersion was obtained. solution and 150 mg urea (mass ratio of graphene oxide to urea is 1:0.25) were fully stirred and mixed evenly, and the above mixed solution was injected into a polytetrafluoroethylene cylinder with an inner diameter of 4 mm through a needle at an extrusion speed of 10 mL / h. Shaped microchannel and sealed at both ends, placed in an oven and heated at 100°C for 1h, then hydrothermally reacted at 180°C for 4h to obtain amino-functionalized graphene fibers; then cooled the cylindrical microchannel to room temperature Open the seals at both ends, and dry at 80°C to obtain dehydrated amino-functionalized graphene fibers; place the dried ami...

Embodiment 3

[0060] Using 500-mesh natural graphite flakes as raw material, the graphene oxide aqueous solution was prepared according to Hummers' improved method, and after centrifugation and concentration at a speed of more than 10,000 rpm for 30 minutes, a graphene oxide dispersion of 8 mg / mL was obtained; 30 mL of the graphene oxide dispersion was obtained. Liquid and 1200mg of dicyandiamide (the mass ratio of graphene oxide and dicyandiamide is 1:5) are fully stirred and mixed evenly, and the above-mentioned mixture is injected through a needle with an inner diameter of 8 mm at an extrusion speed of 100mL / h. In the glass cylindrical microchannel and sealed at both ends, put it in an oven and heat it at 70°C for 6h, then hydrothermally react at 140°C for 10h to obtain amino-functionalized graphene fibers; then the cylindrical slender pipe After cooling to room temperature, open the seals at both ends, and dry at 100°C to obtain dehydrated amino-functionalized graphene fibers with furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com