Method for preparing cerium, molybdenum and cobalt composite oxide selective denitration catalyst from dimethylamine

A composite oxide and denitrification catalyst technology, which is applied in the field of catalyst preparation, can solve the problems of widening catalyst operating temperature, low NOx removal rate, poor resistance to sulfur and water, etc., and achieves good industrial application prospects, strong anti-poison performance, The effect of wide operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

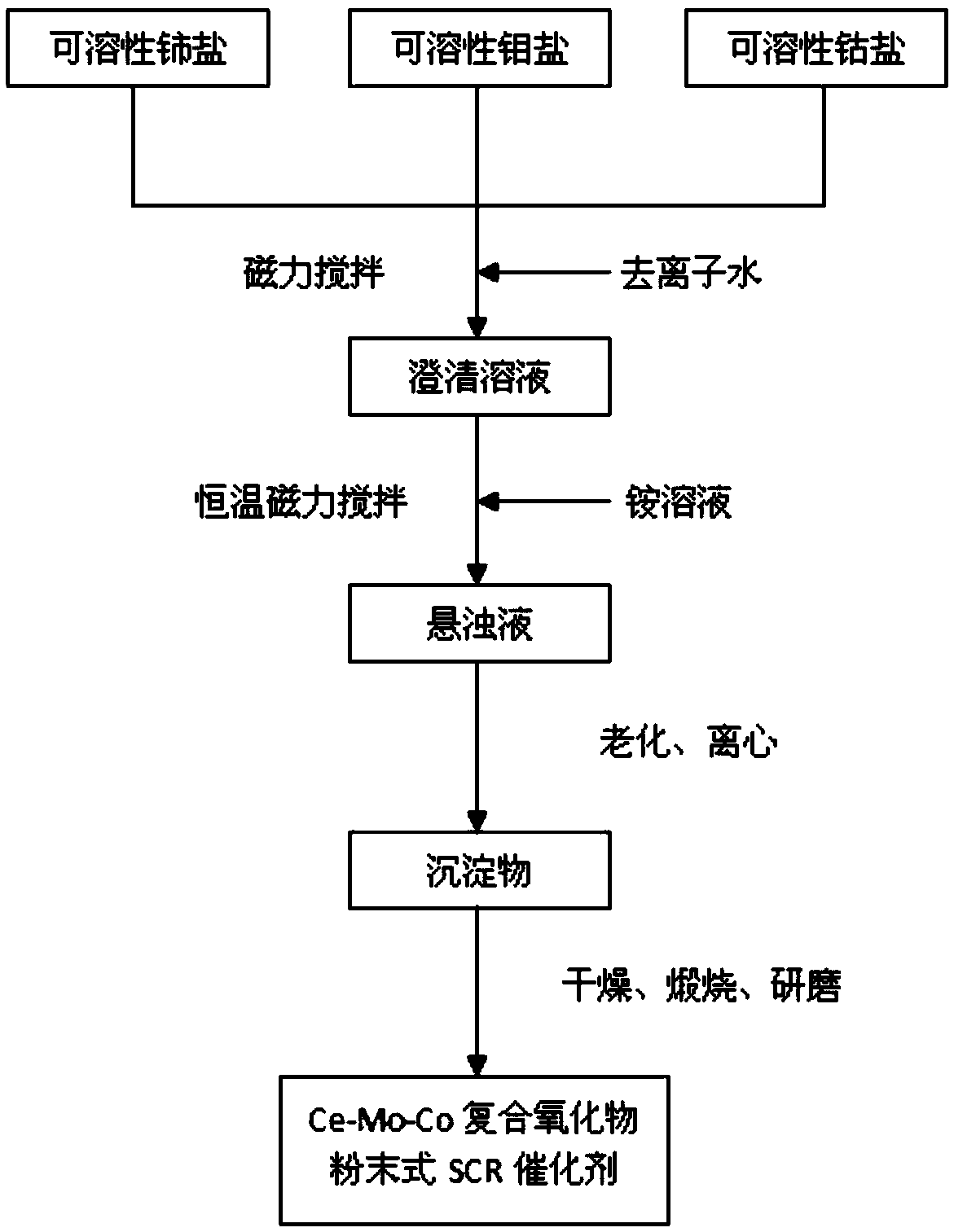

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 21.7g of Ce(NO 3 ) 3 ·6H 2 O, 1.77g of (NH 4 ) 6 Mo 7 o 24 4H 2 O and 0.728g of Co(NO 3 ) 2 ·6H 2 O, dissolved in 100 mL of deionized water (molar ratio Ce: Mo: Co = 1: 0.2: 0.05), magnetically stirred until completely dissolved;

[0034] (2) Place the obtained clear liquid in a heat-collecting stirrer, keep the temperature at 90° C., slowly add 25% ammonia water dropwise, adjust the pH to 12, stop the dropwise addition, and stir and age at room temperature for 4 hours;

[0035] (3) Centrifuge the obtained suspension, and dry the lower part of the precipitate at 110°C for 8 hours;

[0036] (4) The material obtained in (3) was calcined at 400°C for 4h, ground, and passed through a 200-mesh sieve to obtain CeMo x co y o z Composite oxide type SCR catalyst;

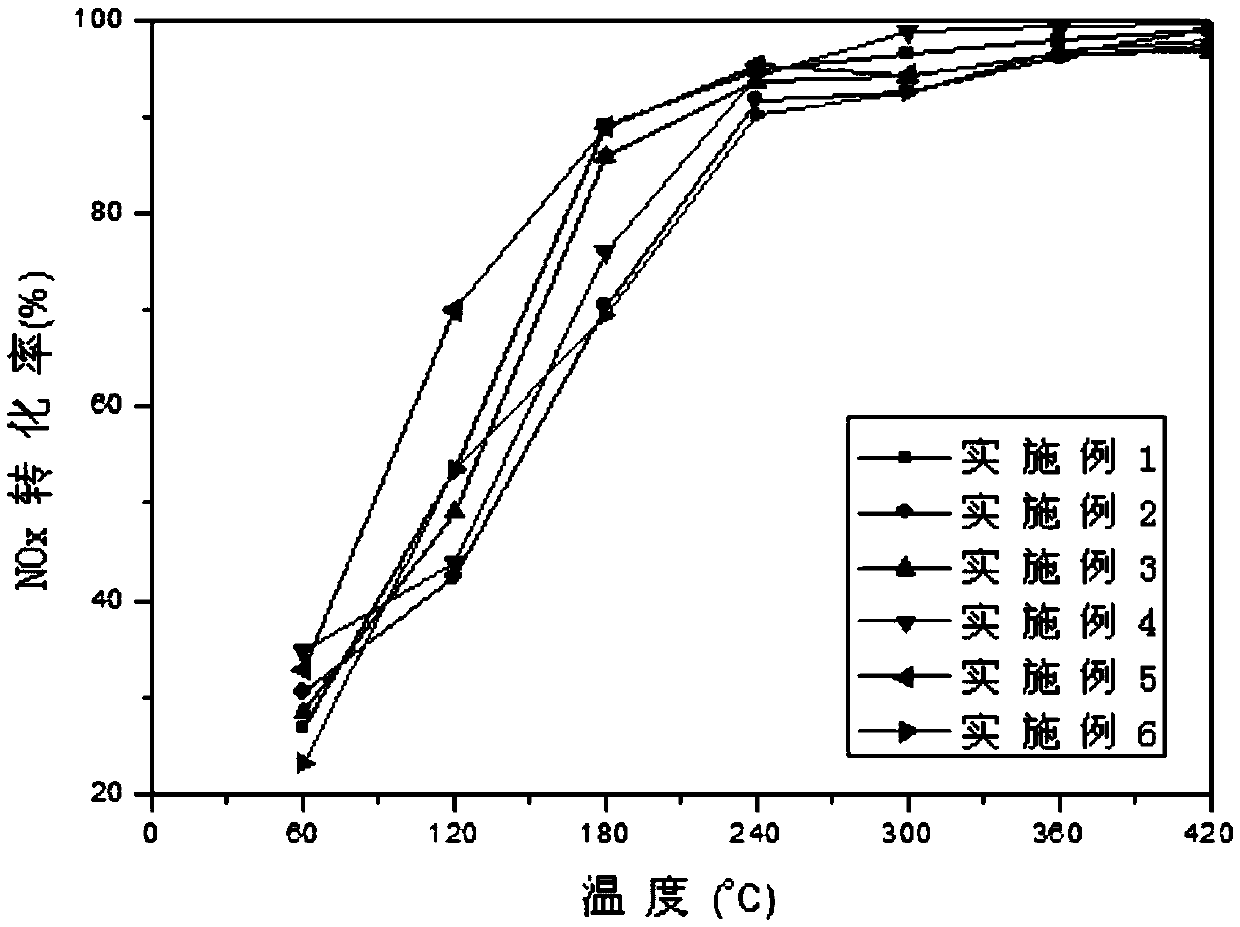

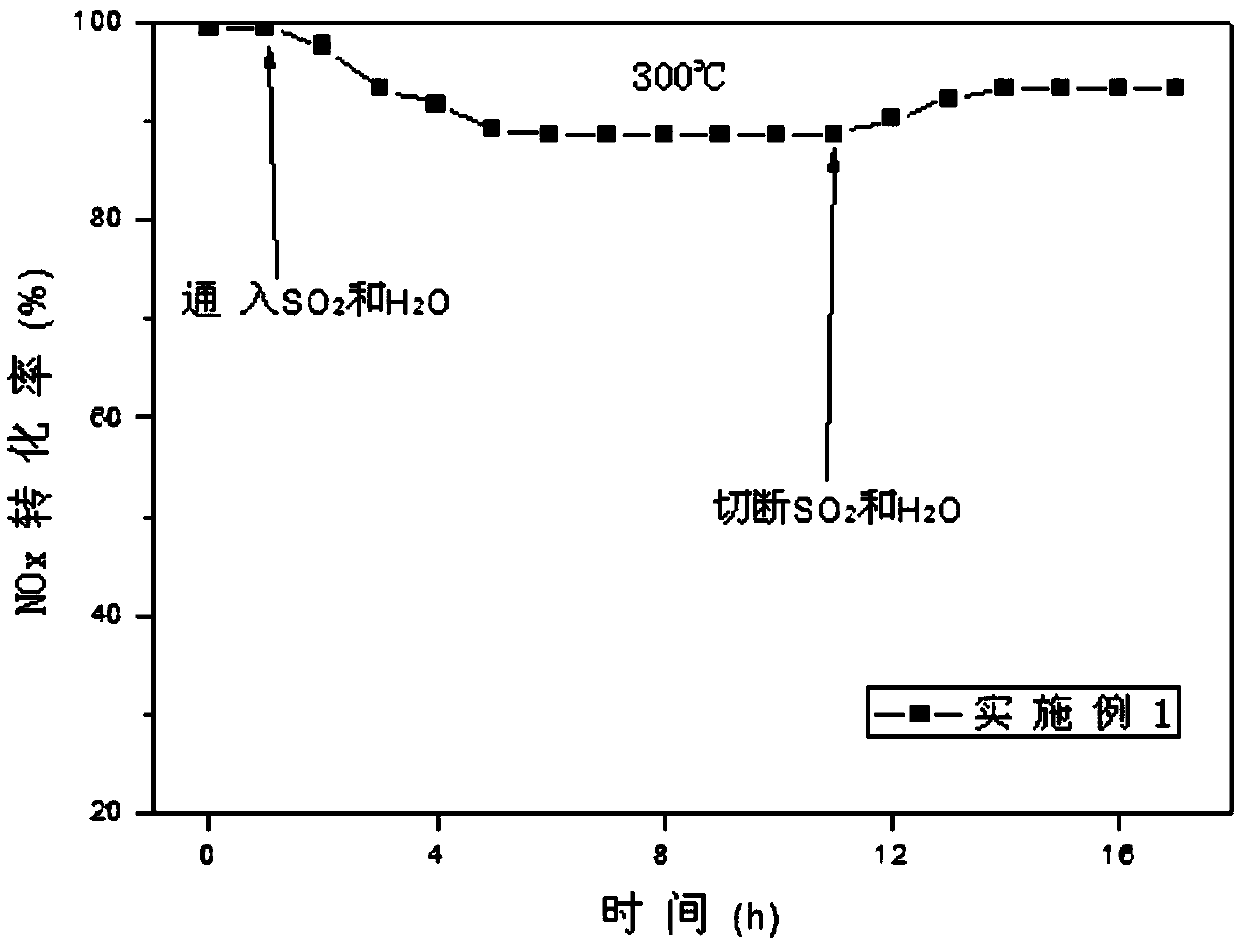

[0037] Characterized by BET, the prepared CeMo 0.2 co 0.05 o z (5 and 10 are Mo / Ce molar ratio and Co / Ce molar ratio respectively, and z is the number of oxygen atoms) The specific surface a...

Embodiment 2

[0047] (1) Weigh 0.356g of Ce 2 (SO 4 ) 3 ·8H 2 O, 0.0887g of Mo(NO 3 ) 3 ·5H 2 O and 28.5 g of CoSO 4 ·7H 2 O, dissolved in 100 mL of deionized water (molar ratio Ce: Mo: Co = 1: 0.2: 100), magnetically stirred until completely dissolved;

[0048] (2) Place the obtained clear liquid in a heat-collecting stirrer, keep the temperature at 80° C., slowly add the urea solution dropwise, adjust the pH to 11, stop the dropwise addition, and stir and age at room temperature for 3 hours;

[0049] (3) Centrifuge the resulting suspension, and dry the lower part of the precipitate at 100°C for 10 hours;

[0050] (4) The material obtained in (3) was calcined at 500°C for 5h, ground, and passed through a 200-mesh sieve to obtain CeMo x co y o z Composite oxide type SCR catalyst;

[0051] Characterized by BET, the prepared CeMo 0.2 co 100 o z The specific surface area of the powder catalyst is 159m 2 / g.

[0052] The catalytic activity of the catalyst was evaluated in a f...

Embodiment 3

[0056] (1) Weigh 0.373g of CeCl 3 ·7H 2 O, 27.3g of MoCl 5 and 0.0119g of CoCl 2 ·6H 2 O, dissolved in 100 mL of deionized water (molar ratio Ce: Mo: Co = 1: 100: 0.05), magnetically stirred until completely dissolved;

[0057] (2) Place the obtained clear liquid in a heat-collecting stirrer, keep the temperature at 30°C, slowly add ammonium carbonate solution dropwise, adjust the pH to 8, stop the dropwise addition, and stir and age at room temperature for 4 hours;

[0058] (3) Centrifuge the obtained suspension, and dry the lower part of the precipitate at 120°C for 9 hours;

[0059] (4) The material obtained in (3) was calcined at 600°C for 7 hours, ground, and passed through a 200-mesh sieve to obtain CeMo x co y o z Composite oxide type SCR catalyst;

[0060] Characterized by BET, the prepared CeMo 100 co 0.05 o z The specific surface area of the powder catalyst is 176m 2 / g.

[0061] The catalytic activity of the catalyst was evaluated in a fixed bed react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com