Transparent super-amphiphobic surface layer and layer-by-layer in-situ spraying reaction preparation method

A super-amphiphobic surface, transparent technology, applied to the surface coating device, special surface, coating and other directions, can solve the problems of inability to large-scale application, high comprehensive production cost, high equipment requirements, to eliminate phase separation phenomenon, the effect of improving transparency and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

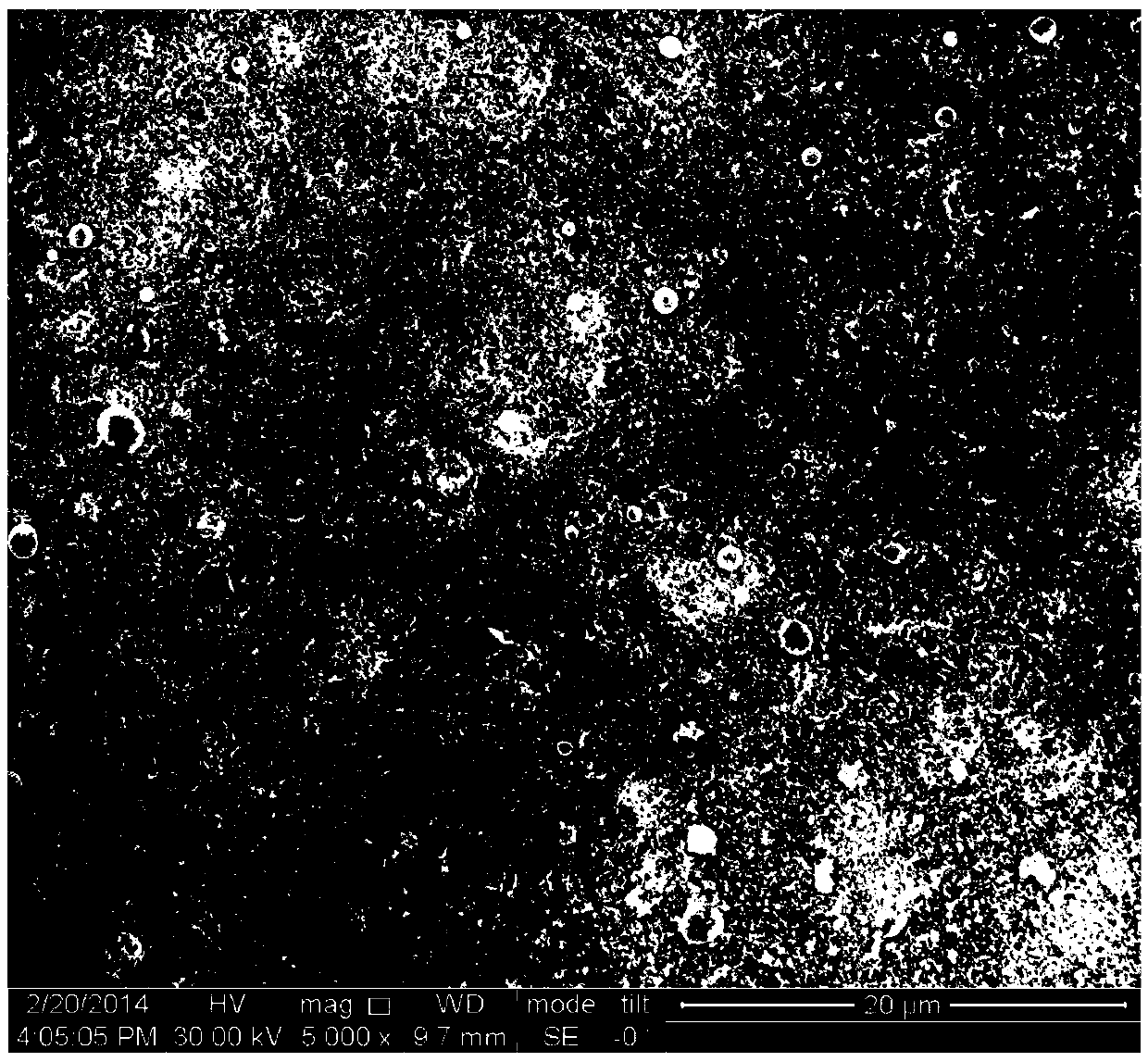

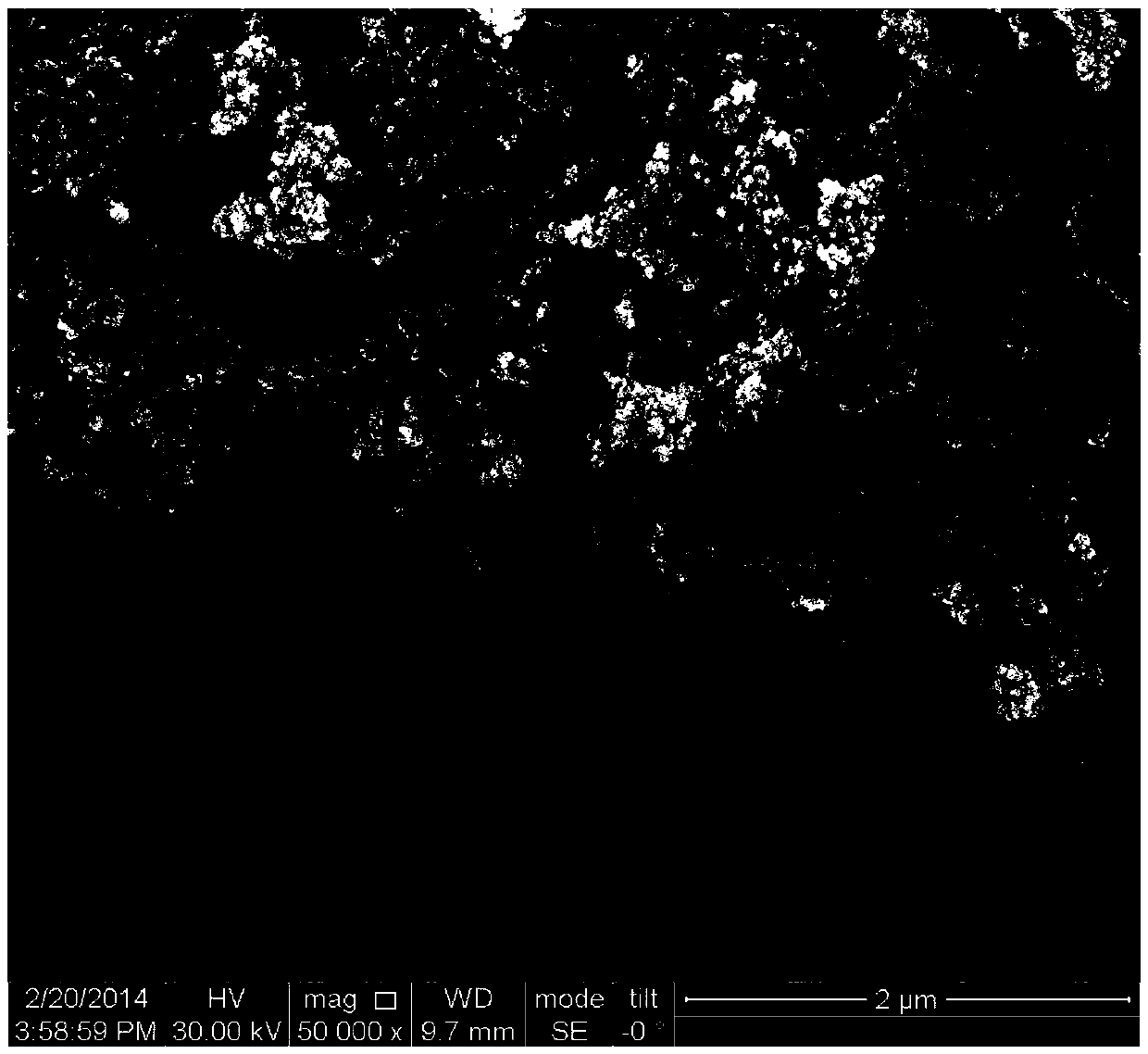

[0039] (1) Add the hydrophobic transparent fluorocarbon resin and its corresponding curing agent into the compatible solvent ethyl acetate, and disperse for 5 minutes under the condition of ultrasonic frequency of 40kHz until the resin is completely dissolved to obtain a primer resin solution with a concentration of 5mg / mL. Add hydrophilic fumed silica with a diameter of 15-40nm into ethanol, and sonicate for 15min to form a nanoparticle solution with a concentration of 10mg / mL. That is, the required primer spraying liquid and topcoat nano particle spraying liquid are obtained.

[0040] (2) Primer coating spraying: wipe the glass slide with a clean cotton cloth, and dry it at room temperature. Use a commercial spray gun with a nozzle diameter of 0.5-2mm, use compressed air as the carrier, adjust the spray spot to a fan shape, the nozzle is 10-20cm away from the surface to be sprayed on the substrate, and move from left to right at a speed of 2-5cm / s from top to bottom Spray t...

Embodiment 2

[0044] (1) Add transparent acrylate and polyurethane to acetone in turn, disperse for 30 minutes under 40kHz frequency ultrasonic conditions until the resin is completely dissolved, add curing agent polyisocyanate, stir for 10 minutes, and obtain a primer resin solution with a concentration of 20mg / mL. Add hydrophilic fumed silica with a diameter of 15-40 nm into ethanol, and ultrasonicate for 5 min to form a nanoparticle solution with a concentration of 5 mg / mL. That is, the required primer spraying liquid and topcoat nano particle spraying liquid are obtained.

[0045] (2) Primer coating spraying: Wipe the metal copper sheet with a clean cotton cloth, wash off the surface oil with deionized water and ethanol, and dry at room temperature. Use a commercial spray gun with a nozzle diameter of 0.5-2mm, use compressed air as the carrier, adjust the spray spot to a fan shape, the nozzle is 10-20cm away from the surface to be sprayed on the substrate, and move from left to right at...

Embodiment 3

[0049] (1) Add epoxy resin to ethanol, disperse for 30 minutes under 40kHz frequency ultrasonic conditions until the resin is completely dissolved, add curing agent ethylenediamine, stir for 15 minutes, and obtain a primer resin solution with a concentration of 10 mg / mL. Add hydrophilic fumed silica with a diameter of 15-40 nm into ethanol, and ultrasonicate for 40 min to form a nanoparticle solution with a concentration of 20 mg / mL. That is, the required primer spraying liquid and topcoat nano particle spraying liquid are obtained.

[0050] (2) Spraying of the primer coating: Wipe the plastic PET sheet with a clean cotton cloth, wash off the surface oil with deionized water and ethanol, and dry at room temperature. Use a commercial spray gun with a nozzle diameter of 0.5-2mm, use compressed air as the carrier, adjust the spray spot to a fan shape, and the nozzle is 10-20cm away from the surface to be sprayed on the substrate, from left to right at a speed of 2-5cm / s from top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com