Nanometer dysprosium oxide preparation method

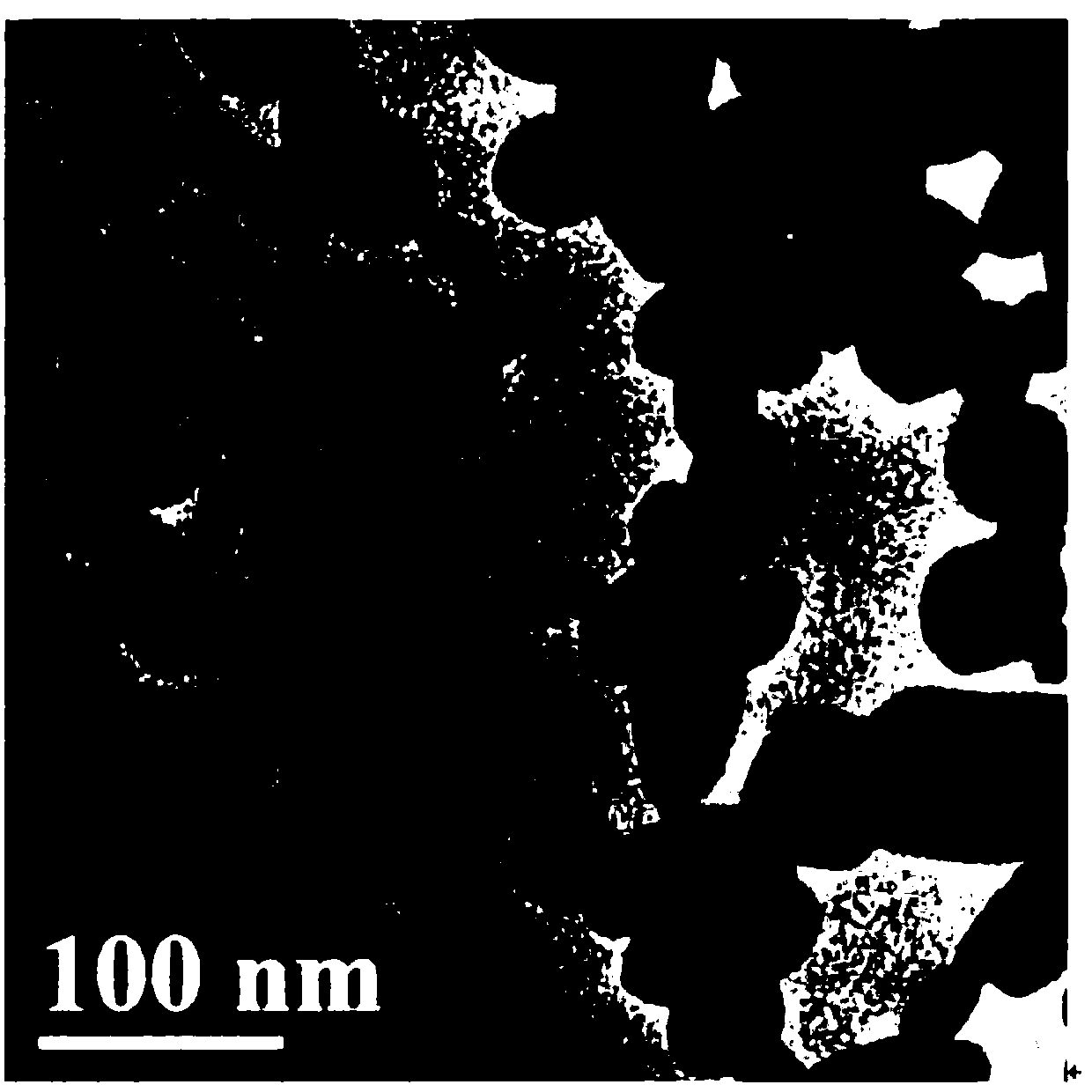

A technology of nano-dysprosium oxide and dysprosium nitrate, which is applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of insufficient uniformity of nano-dysprosium oxide particles, insufficient dispersion, and inability to prepare, so as to achieve large specific surface area and process technology Simple, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: add in reaction kettle and be mixed with pure water and be mixed with dysprosium nitrate that concentration is 0.4mol / L, volume is 13.4L, after measuring temperature is 15 degree, then take by weighing analytical pure sodium carbonate 1KG, be mixed with pure water The concentration is 0.4mol / L, the volume is 23.58L, and the temperature is 15 degrees. Weigh 100 grams of PEG-20000 surfactant with an oxide mass ratio of 10%, add 1L of pure water, heat to dissolve it into a liquid, and dissolve the PEG -20000 was put into dysprosium nitrate and mixed and stirred for 15 minutes, and finally sodium carbonate was added dropwise evenly. After finishing, continue to stir for 0.5 hours, age for 2 hours, soak and wash with hot pure water above 95 degrees in the suction filter barrel, wash about 500L with water, and finally filter dry, add 200ml of n-butanol to the filter cake, stir evenly and thoroughly , put it in a bowl, and heat it at 800 degrees for a total of 4 ...

Embodiment 2

[0014] Embodiment 2: add in reaction kettle and be mixed with pure water and be mixed with the dysprosium nitrate that concentration is 0.4mol / L, volume is 47.66L, after measuring temperature is 17 degree, then take by weighing analytical pure sodium carbonate 4KG, be mixed with pure water The concentration is 0.4mol / L, the volume is 94.34L, and the temperature is 18 degrees. Weigh 320 grams of PEG-20000 surfactant with an oxide mass ratio of 8%, add 3.2L of pure water, and heat to dissolve it into a liquid. Put PEG-20000 into dysprosium nitrate and mix and stir for 15 minutes, and finally add sodium carbonate dropwise evenly. The dropping time is 141 minutes. From this, it can be calculated that the adding rate is 0.67 L / min. The flow and adding speed are controlled by the governor. After the addition, continue to stir for 0.5 hours, age for 2 hours, soak and wash with hot pure water above 95 degrees in the suction filter barrel, wash about 2000L with water, and finally filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com