Ammonium dimolybdate automatic continuous crystallization production process

An ammonium dimolybdate and production process technology, applied in the directions of molybdenum compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problem that the particle size of ammonium dimolybdate products varies greatly, the control of process parameters is difficult, and the degree of automation is low. problems, to achieve the effect of wide adaptability of raw materials, uniform growth of product particle size, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

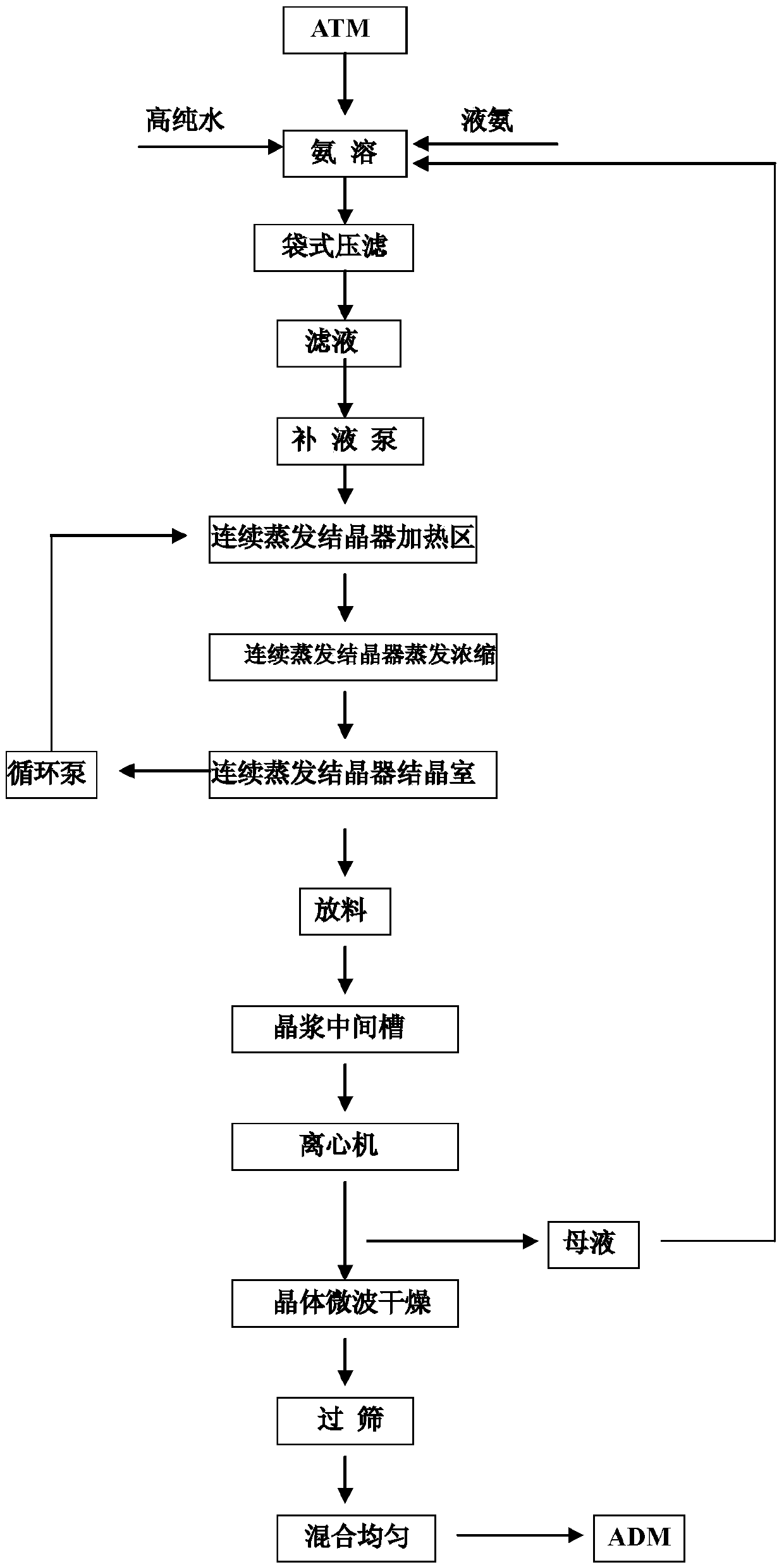

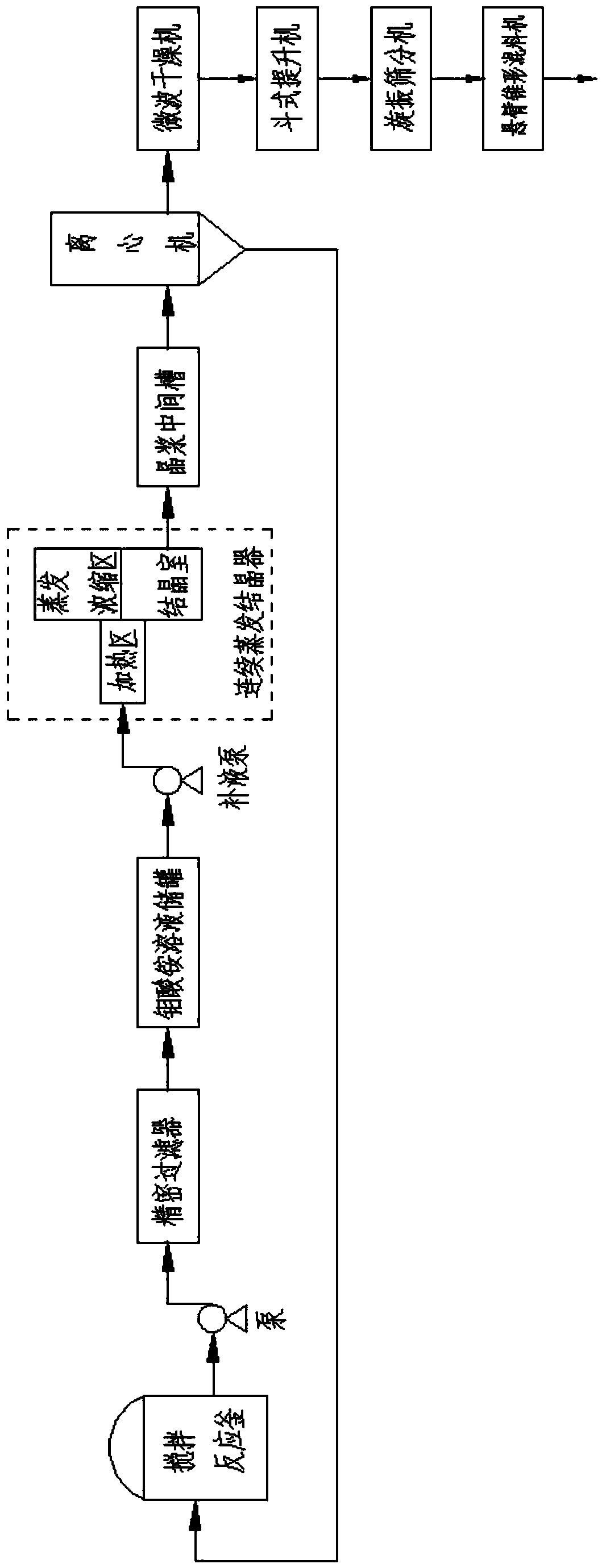

[0023] like figure 1 and figure 2 As shown, the ammonium dimolybdate continuous crystallization system is adopted, which consists of a stirred reactor, a pump, a precision filter, an ammonium molybdate solution storage tank, a liquid replenishment pump, a continuous evaporation crystallizer, a middle tank for crystal slurry, a centrifuge, a microwave drying Machine, bucket elevator, rotary vibrating screener and arm cone mixer are connected in sequence. The continuous evaporation crystallizer is divided into a heating area on the left, an evaporation concentration area on the right of the heating area and an evaporation The crystallization chamber on the lower side of the concentration zone. First, start stirring during the process of adding ATM (wet ammonium tetramolybdate) into the stirred reactor with high-purity water and liquid ammonia, and adjust the density of the ammonia solution to 1.20g / cm 3 , The pH value is 8.5, so that the temperature of the solution reaches 70...

Embodiment 2

[0026] Start stirring in the process of adding ATM (wet ammonium tetramolybdate) in the reactor of adding the mother liquor in high-purity water, liquefied ammonia and embodiment 1, adjust ammonia solution density 1.23g / cm 3 , the pH value is 8.7, so that the reaction temperature of the solution reaches 75 °C; pump into the precision filter, pressurize and filter under the pressure of 0.3MPa, the filtrate enters the ammonium molybdate solution storage tank, and then adjust the rehydration pump to keep the ammonium molybdate solution in the storage tank The amount of ammonia liquid feed in 1.6m 3 / h, circulating into the continuous evaporation crystallizer, the heating, evaporation and crystallization of the solution are simultaneously operated in the heating area, evaporation concentration area and crystallization chamber of the continuous evaporation crystallizer. The heating temperature in the heating zone is 115°C, keep the temperature in the heating zone at 103°C, stop fee...

Embodiment 3

[0029] Start stirring in the process of adding ATM (wet ammonium tetramolybdate) in the reactor of the mother liquor in adding high-purity water, liquefied ammonia and embodiment 2, adjust ammonia solution density 1.25g / cm 3 , The pH value is 8.8, so that the reaction temperature of the solution reaches 60°C; pump into the precision filter, pressurize and filter under the pressure of 0.25MPa, and the filtrate enters the ammonium molybdate solution storage tank. Then adjust the replenishment pump to keep the ammonia solution feed rate in the ammonium molybdate solution storage tank at 1.8m 3 / h, circulating into the oslo crystallizer, the heating, evaporation and crystallization of the solution are simultaneously operated in the heating zone, evaporation concentration zone and crystallization chamber of the oslo crystallizer; the heating temperature in the heating zone is 120°C, and the temperature in the heating zone is kept at 104°C, the liquid level in the evaporation concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com